A scale-up method for CVD-grown large-area graphene

A graphene, large-area technology, applied in the field of high-efficiency CVD growth of large-area graphene, can solve problems such as uneven growth of graphene, and achieve the effects of increasing the loading capacity of a single batch, increasing the output, and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

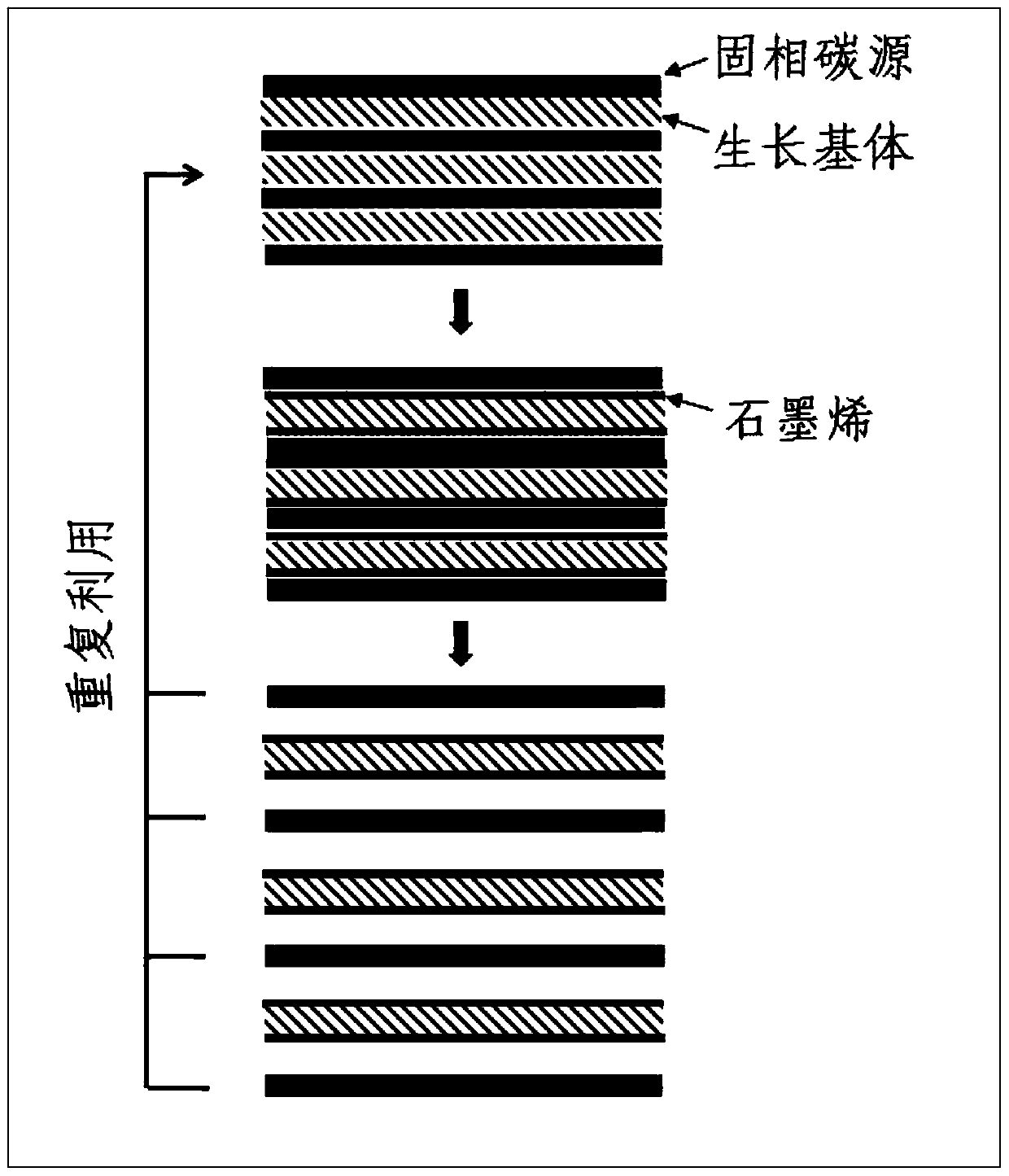

[0028] Such as figure 1 As shown, metal copper foil (25 μm thick) was used as the growth substrate, and carbon felt (50 μm thick) was used as the solid-phase carbon source. The flat large-area copper foil and carbon felt are stacked alternately, and the number of layers is 200 layers. Put the laminated copper foil and carbon felt into an electrically heated CVD furnace for growth. First, vacuumize the furnace chamber until the pressure is less than 1Pa, then feed in hydrogen gas with a flow rate of 100 sccm, and maintain the pressure at 50Pa; within 30 minutes, raise the furnace temperature to 1000°C, keep it for 10 minutes and then cool it down to room temperature with the furnace. Complete CVD growth. High-quality large-area single-layer graphene is formed on both the upper and lower surfaces of the copper foil, while the carbon felt can be reused for CVD growth.

Embodiment 2

[0030] The difference with Example 1 is:

[0031] Other materials are used as solid-phase carbon sources, including flexible graphite paper, carbon nanotube film, fullerene, carbon black or silicon carbide, etc.; the growth is carried out by atmospheric pressure CVD process, and the carrier gas is argon.

Embodiment 3

[0033] Such as figure 1 As shown, a quartz plate coated with a nickel film (500 nm thick) was used as the growth substrate, and a carbon fiber cloth (200 μm thick) impregnated with epoxy resin was used as the solid-phase carbon source. The nickel film / quartz plate and the carbon fiber / resin cloth are stacked alternately, and the number of layers is 100. The stacked samples were placed in an induction heating CVD furnace for growth. First vacuumize the furnace cavity until the pressure is less than 1Pa, then introduce hydrogen with a flow rate of 50sccm, and maintain the pressure at 20Pa; within 3 minutes, raise the furnace temperature to 1000°C and keep it for 1 minute; then stack the samples Perform rapid cooling to room temperature at a cooling rate of 15° C. / second to complete CVD growth. High-quality large-area few-layer graphene is formed on the surface of the nickel film, and the carbon fiber cloth can be reused for CVD growth.

[0034] The results of the examples sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com