Method of preparing porous silicon carbide support at low temperature

A porous silicon carbide and support technology, applied in the field of porous ceramic materials, can solve the problems of high energy consumption and achieve the effects of lower sintering temperature, good gas permeability and chemical stability, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

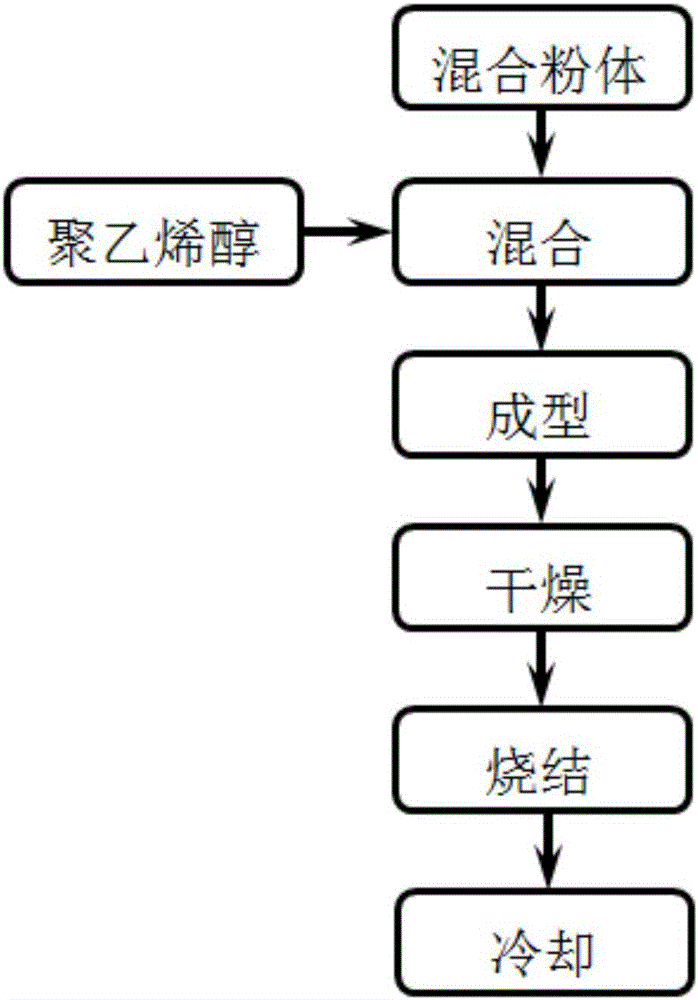

Method used

Image

Examples

Embodiment 1

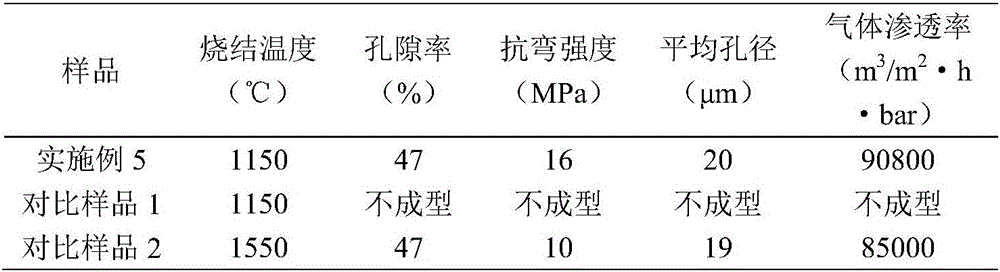

[0027] Calculated by mass ratio, 4% of sodium dodecylbenzenesulfonate (SDBS) powder, 10% of 2 μm zirconia and 86% of 100 μm silicon carbide powder are uniformly mixed. Add polyvinyl alcohol (PVA) aqueous solution with a mass concentration of 10% of the mass of 1% of the mixed powder, mix thoroughly and evenly, and then prepare the tubular porous silicon carbide support body by extrusion method from the mixed powder. Dry the pressed support body in an oven at 60°C for 60 minutes, then put it into a high-temperature electric furnace to raise the temperature to 100°C at 1°C / min, keep it warm for 1 hour, then raise the temperature to 500°C at 2°C / min and Keep it warm for 1 hour, then raise the temperature to 900°C at 2°C / min, then raise the temperature to 1150°C at 1°C / min, keep it warm for 4 hours, and then cool down naturally.

[0028] The test results are: the porosity of the prepared porous silicon carbide support is 27.7%, and the bending strength is 13.6MPa.

Embodiment 2

[0030] Calculated by mass ratio, 8% SDBS powder, 10% 20 μm activated carbon powder, 10% 4 μm zirconia and 72% 100 μm silicon carbide powder were uniformly mixed. Add 3% of the mixed powder mass and 8% PVA aqueous solution, mix thoroughly and evenly, and then prepare the tubular porous silicon carbide support body by extrusion method from the mixed powder. Dry the pressed support body in an oven at 90°C for 70 minutes, then put it into a high-temperature electric furnace to raise the temperature to 100°C at 1°C / min, keep it warm for 2 hours, then raise the temperature to 500°C at 2°C / min and Keep it warm for 2 hours, then raise the temperature to 900°C at 2°C / min, then raise the temperature to 1150°C at 1°C / min, keep it warm for 5 hours, and then cool down naturally.

[0031] The test results are: the porosity of the prepared porous silicon carbide support is 40.7%, and the bending strength is 27.57MPa.

Embodiment 3

[0033] Calculated by mass ratio, 8% SDBS powder, 15% 10 μm activated carbon powder, 5% 5 μm zirconia and 72% 50 μm silicon carbide powder were uniformly mixed. Add 3% PVA aqueous solution with a mass fraction of 8% and mix thoroughly and uniformly, and then prepare the flat porous silicon carbide support body by extrusion method from the mixed powder. Dry the pressed support body in an oven at 90°C for 80 minutes, then put it into a high-temperature electric furnace to raise the temperature to 100°C at 1°C / min, keep it warm for 2 hours, then raise the temperature to 500°C at 3°C / min and Keep it warm for 3 hours, then raise the temperature to 900°C at 3°C / min, then raise the temperature to 1150°C at 1°C / min, keep it warm for 5h, and then cool down naturally.

[0034] The test results are: the porosity of the prepared porous silicon carbide support is 43.7%, and the bending strength is 21.3 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com