Magnetic cadmium ion-imprinted polymer and preparation method thereof

A technology for imprinting polymers and cadmium ions, which is applied in the field of food safety and can solve the problem of less imprinting of magnetic ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Example 1 Preparation method of magnetic cadmium ion imprinted polymer

[0078] The preparation method of magnetic cadmium ion imprinted polymer comprises the following steps:

[0079] S1. Preparation of Fe 3 o 4 Particles:

[0080] Weigh 0.02mol Fe 3 Cl 3 ·6H 2 O, 0.012mol FeCl 2 4H 2 O was placed in a 250ml Erlenmeyer flask, dissolved in 100ml of ultrapure water under nitrogen, heated and stirred in a constant temperature magnetic stirrer to 80°C, added 10ml of ammonia water and 2ml of PEG200, heated and stirred for 3h, the reaction was completed, cooled to room temperature, and After separating and removing the supernatant, wash with ethanol and ultrapure water three times each, dry in an oven at 60°C, and grind to obtain Fe 3 o 4 powder;

[0081] S2. Preparation of Fe 3 o 4 @SiO 2 :

[0082] Weigh 0.5g Fe 3 o 4 Disperse the powder into a mixed solution of 100ml distilled water, 50ml ethanol and 10ml ammonia water, then add 0.5ml TEOS dropwise, and st...

Embodiment 2

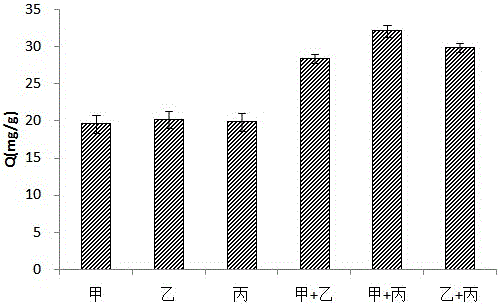

[0087] Example 2 Optimization of preparation process - selection of functional monomers (methacrylic acid and acrylamide)

[0088] 1. The preparation method is the same as in Example 1, except that the functional monomers used in step S4—methacrylic acid and acrylamide—are replaced by the following different combinations:

[0089] (1) Methacrylic acid;

[0090] (2) Vinylpyridine;

[0091] (3) Acrylamide;

[0092] (4) Methacrylic acid and vinylpyridine;

[0093] (5) Methacrylic acid and acrylamide;

[0094] (6) Acrylamide and vinylpyridine.

[0095] The functional monomers were screened by comparing the cadmium adsorption capacity of different combinations of functional monomers.

[0096] 2. The results are attached figure 1 As shown, in the preparation of magnetic cadmium ion-imprinted polymer (M-IIP), the adsorption capacity of ion-imprinted polymers prepared by bifunctional monomers was higher than that of ion-imprinted polymers prepared by single-functional monomers. ...

Embodiment 3

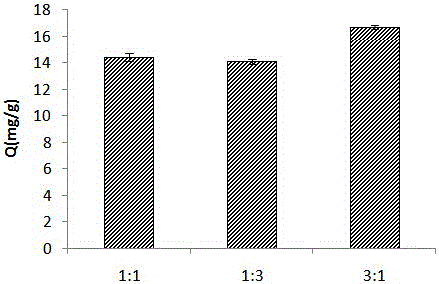

[0097] Example 3 Optimization of the preparation process - selection of the ratio of methacrylic acid and acrylamide

[0098] 1. The preparation method is the same as in Example 1, except that the ratios of the functional monomers used in step S4—methacrylic acid and acrylamide—are different: 1:1, 1:3, and 3:1, respectively.

[0099] 2. The results are attached figure 2 As shown, the adsorption capacity of cadmium is the highest when the ratio of methacrylic acid and acrylamide is 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com