Immobilized lipase, preparation method thereof and application in catalyzed synthesis of glyceride type PUFA

An immobilized lipase, glyceride type technology, applied in the direction of immobilization on/in organic carriers, fermentation, etc., can solve the problems of low triglyceride content, low enzyme catalysis efficiency, low substrate conversion rate, etc., Achieve the effect of saving production cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of immobilized lipase MAS1

[0026] 1.1 Pretreatment and screening of immobilized resin

[0027] 10g of XAD1180 / DA201 / HP20 / HP2MGL / AB8 five kinds of macroporous adsorption resins were respectively treated with 30mL 95% ethanol, 5% hydrochloric acid and 2% sodium hydroxide for 24h, 4h, 4h respectively. After each step of treatment, the supernatant was filtered Wash it repeatedly with distilled water until the pH value of the supernatant is 7.0, and then proceed to the next step. Finally, the resin is soaked in 20mmol / L buffer solution with different pH values for 4h, and the filtered resin is placed in Store in a 4°C refrigerator for later use. The purpose of soaking the resin with ethanol and acid and alkali is to drive out the air bubbles in the macropores and remove the residual monomers and compounds in the macropores respectively.

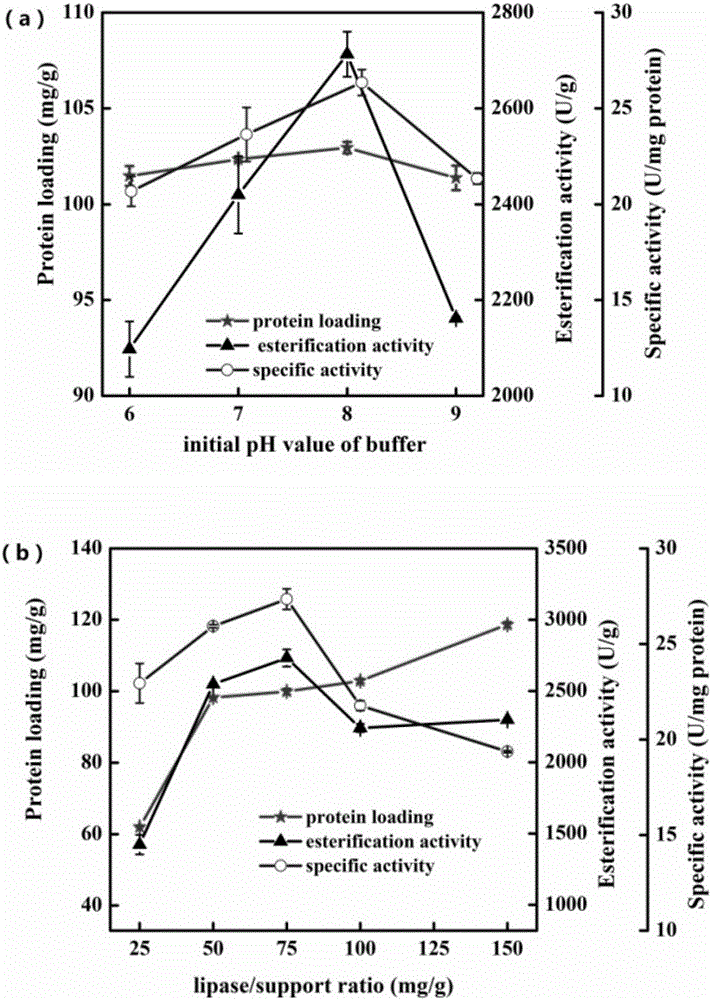

[0028] Mix lipase MAS1 enzyme solution 50mg / g resin, equal volume of 20mM pH8 phosphate buffer, and resin pretreated wit...

Embodiment 2

[0041] Synthesis of n-3PUFA-enriched triglycerides through esterification reaction catalyzed by immobilized lipase MAS1

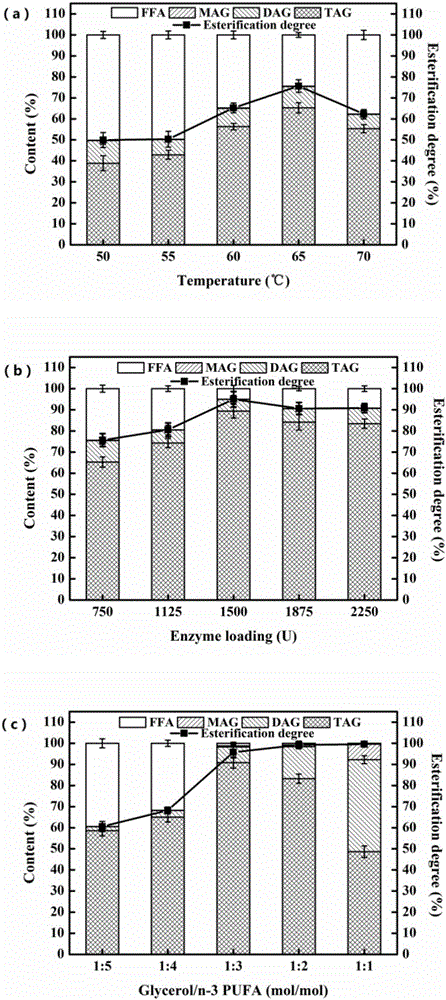

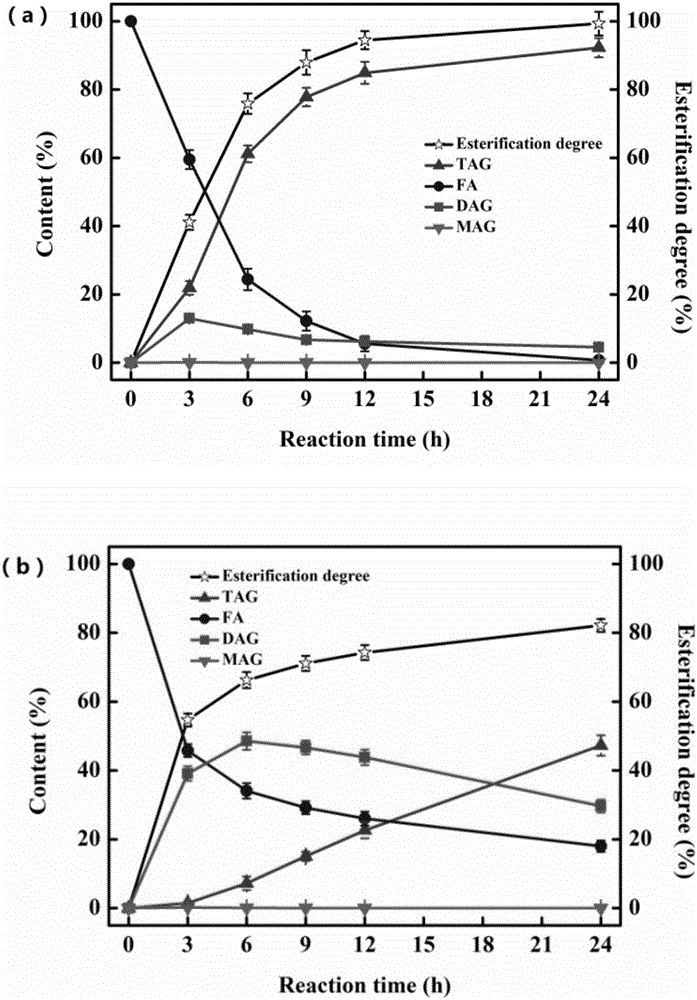

[0042] 10g of substrate (molar ratio of glycerol to PUFA is 1:1, 1:2, 1:3, 1:4, 1:5) was placed in a 250mL Erlenmeyer flask with a stopper, and a certain amount of lipase was added according to the enzyme activity unit ( 750U, 1125U, 1500U, 1875U, 2250U), placed in constant temperature oscillators at different temperatures (50°C, 55°C, 60°C, 65°C, 70°C) for 24 hours of vacuum reaction at a speed of 200rpm, at different reaction times Sampling, HPLC analysis of the composition of the reaction mixture, GC analysis of the fatty acid composition of TAG, and comparison with the esterification reaction catalyzed by Novozym 435 with the same enzyme activity unit under the same conditions.

[0043] Depend on figure 2 (a) It can be seen that under the condition that the molar ratio of glycerol to n-3PUFA is 1:3 and 750 U of immobilized enzyme, when the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Protein adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com