Method for enhancing formation speed of anaerobic ammoxidation granular sludge by controlling reflux ratio

An anaerobic ammonia oxidation and granular sludge technology, applied in chemical instruments and methods, return water treatment, water treatment parameter control, etc. Problems such as poor mixing effect, to achieve the effect of easier separation of mud and water, resistance to changes in external environmental conditions, and prevention of sludge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for controlling the reflux ratio to increase the formation rate of anaerobic ammonium oxidation granular sludge is carried out according to the following steps:

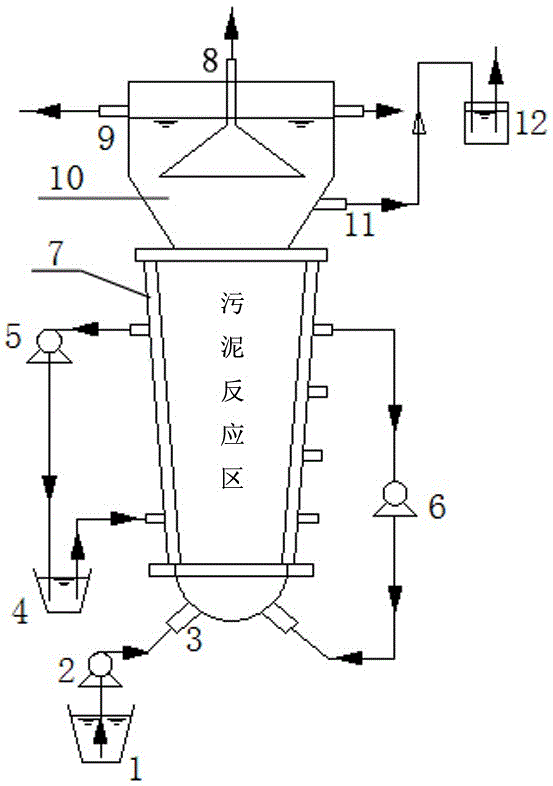

[0027] (1) The sludge reaction zone of the UASB reactor tank is set in the shape of an inverted cone column, and the diameter ratio of the bottom surface of the inverted cone column to the upper surface is 1: (1.1~1.25). The structure of the UASB reactor is as follows figure 1 Shown: The sludge reaction area is heated by a constant temperature water bath, with a two-layer structure inside and outside, the inner layer is the reaction area, and the outer layer is the constant temperature water bath area, and the reactor is protected from light;

[0028] (2) Use the mixture of landfill leachate and sewage plant anaerobic sludge as inoculation sludge to inoculate and acclimatize the UASB reactor, and add polymer flocculant PAM with a molecular weight of 4 to 8 million, in which the MLSS of the inoculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com