Method for producing uniform lamella zinc pyrithione

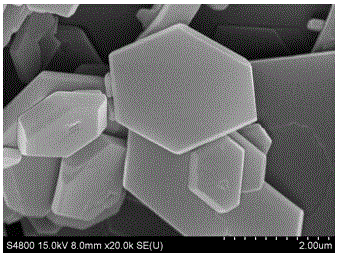

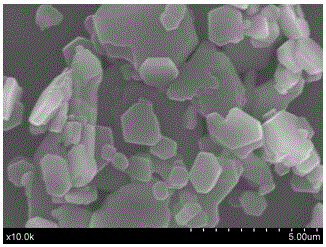

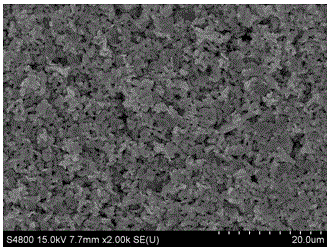

A lamella-crystalline zinc pyrithione, uniform technology, applied in the field of producing uniform lamella-crystalline zinc pyrithione, can solve the problem of large particle size of zinc pyrithione, achieve the effect of improving the sterilization effect and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first step: Oxidation reaction: Add 2-chloropyridine, catalyst and deionized water into the reaction kettle, raise the temperature to 55°C, stir for 1h, slowly add hydrogen peroxide dropwise, raise the temperature to 70°C, keep it warm for 4h, then add dropwise hydrogen oxidation Sodium adjusts the pH value to 7.5 to generate 2-chloro-N-oxypyridine solution;

[0033] Its specific reaction is as follows:

[0034]

[0035] The second step: mercaptolation reaction: add sodium hydrosulfide solution and sodium hydroxide solution dropwise to the reaction kettle of the 2-chloro-N-oxypyridine solution in the first step to adjust the pH to 9, and stir at a temperature of 80°C for 2h , generate 2-mercapto-N-oxypyridine solution;

[0036] Its specific reaction is as follows:

[0037]

[0038] The third step: acid stripping reaction: add hydrochloric acid to the reaction kettle of the 2-mercapto-N-oxypyridine solution in the second step, and adjust the pH value to 3;

...

Embodiment 2

[0048]Example 2: Step 1: Oxidation reaction: Add 2-chloropyridine, catalyst and deionized water into the reactor, heat up to 50°C, stir for 1 hour, slowly add hydrogen peroxide dropwise, heat up to 60°C, keep warm for 3 hours, and then Add dropwise sodium hydroxide to adjust the pH value to 6 to generate 2-chloro-N-oxypyridine solution;

[0049] The second step: mercaptolation reaction: add sodium hydrosulfide solution and sodium hydroxide solution dropwise to the reaction kettle of the 2-chloro-N-oxypyridine solution in the first step to adjust the pH to 8, and stir at a temperature of 70°C for 1h , generate 2-mercapto-N-oxypyridine solution;

[0050] The third step: acid stripping reaction: add hydrochloric acid to the reaction kettle of the 2-mercapto-N-oxypyridine solution in the second step, and adjust the pH value to 2;

[0051] The fourth step: salt formation reaction: add sodium hydroxide solution to the solution in the third step to adjust the pH value to 8, and then...

Embodiment 3

[0055] The first step: Oxidation reaction: Add 2-chloropyridine, catalyst and deionized water into the reaction kettle, raise the temperature to 60°C, stir for 2.5h, slowly add hydrogen peroxide dropwise, raise the temperature to 80°C, keep it warm for 5h, and then add hydrogen dropwise Sodium oxide adjusts the pH value to 8 to generate 2-chloro-N-oxypyridine solution;

[0056] The second step: mercaptolation reaction: add sodium hydrosulfide solution and sodium hydroxide solution dropwise to the reaction kettle of the 2-chloro-N-oxypyridine solution in the first step to adjust the pH to 10, and stir at a temperature of 90°C for 3h , generate 2-mercapto-N-oxypyridine solution;

[0057] The third step: acid stripping reaction: add hydrochloric acid to the reaction kettle of the 2-mercapto-N-oxypyridine solution in the second step, and adjust the pH value to 4;

[0058] The fourth step: salt formation reaction: add sodium hydroxide solution to the solution in the third step to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com