A kind of elastic renewable polyester and preparation method thereof

A technology of recycled polyester and elasticity, applied in the field of textile fibers or chemical fibers, can solve the problems of low moisture absorption rate of polyester, and achieve the effect of improving elasticity and hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

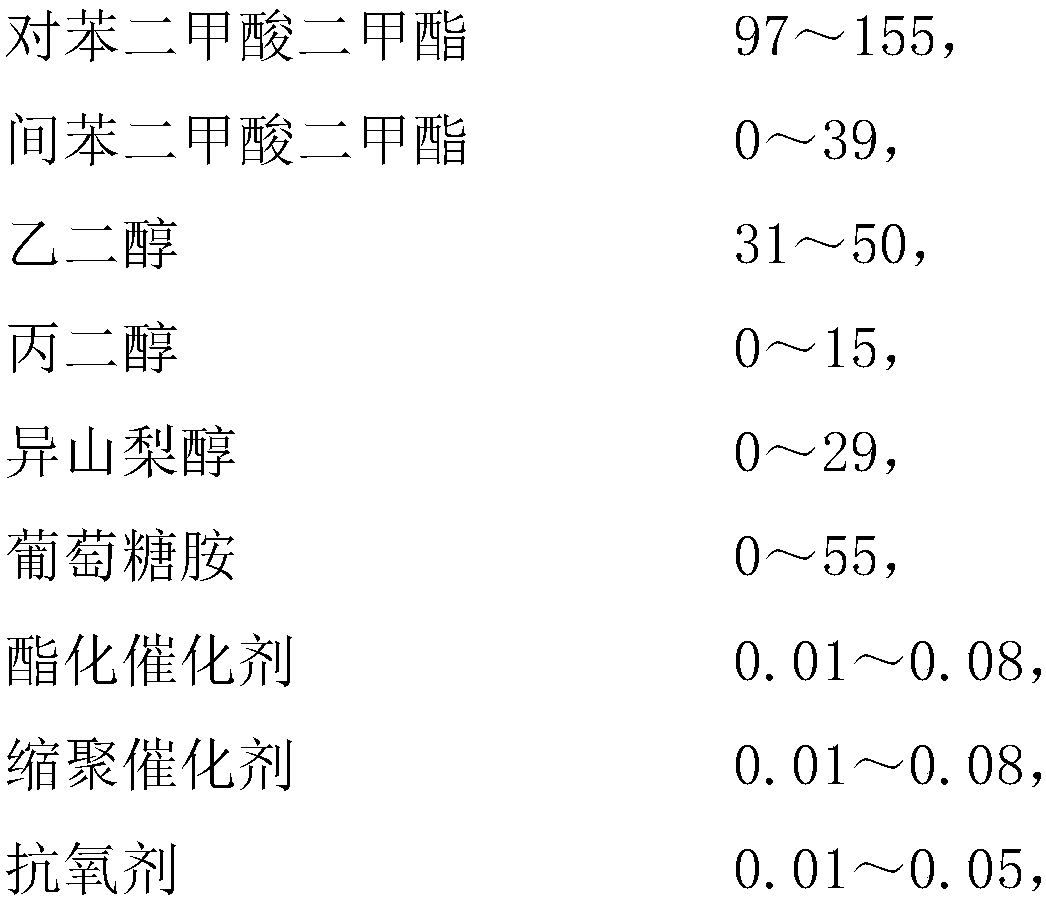

[0020] (1) group distribution ratio:

[0021]

[0022] (II) preparation steps:

[0023] (1) exhaust the air in the polyester reaction device with nitrogen, under the protection of nitrogen, 97 parts of dimethyl terephthalate, 31 parts of ethylene glycol, 0.01 part of zinc acetate and 0.01 part of 2,6- Put di-tert-butyl-4-methylphenol into the reaction bottle, start heating, stirring rate 300r / min, keep warm for 30 minutes when the temperature rises to 165°C, then raise the temperature to 185°C, react for 60 minutes, and protect the whole process with nitrogen , the unit is parts by mass;

[0024] (2) Add 0.01 part of antimony oxide, raise the temperature to 265°C, gradually reduce the pressure in the reactor until the residual pressure is 1kPa, and the reaction time is 60 minutes;

[0025] (3) Warming up to 275°C, gradually reducing the pressure in the reactor until the residual pressure is 0.1kPa, and the reaction time is 120 minutes;

[0026] (4) cooling to room temper...

Embodiment 2

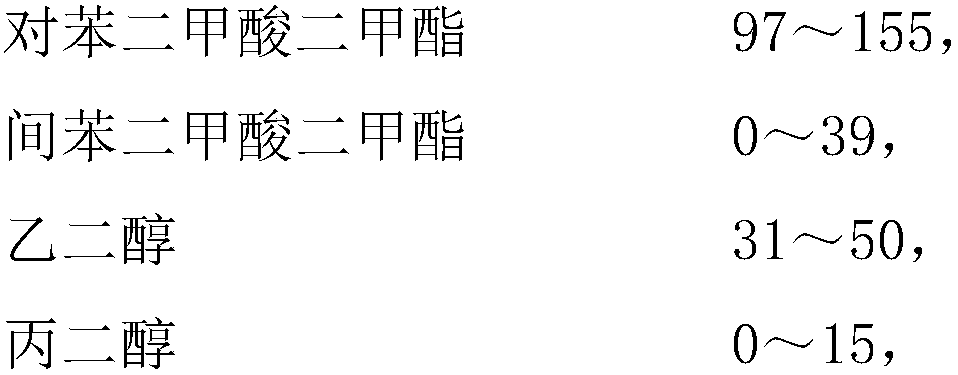

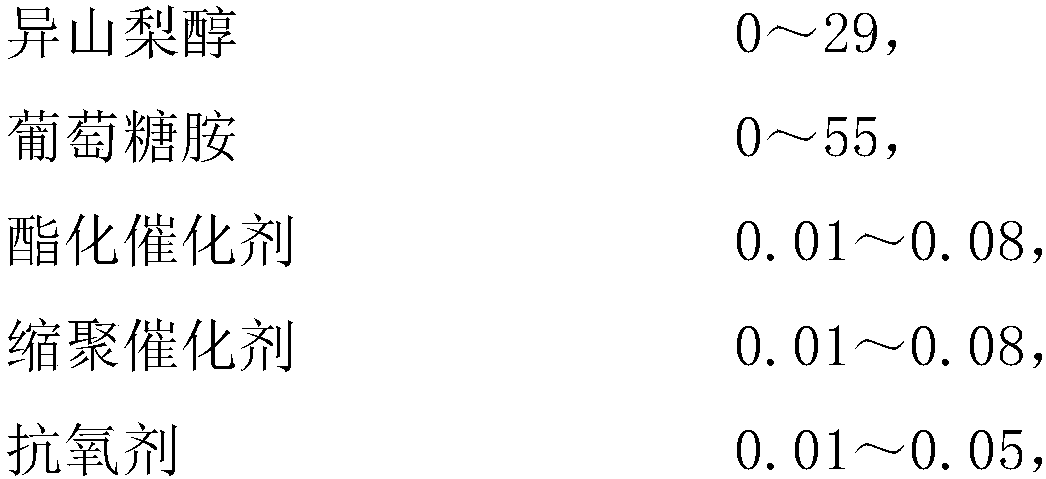

[0029] (I) Group distribution ratio

[0030]

[0031] (II) preparation steps:

[0032] (1) exhaust the air in the polyester reaction device with nitrogen, under the protection of nitrogen, 97 parts of dimethyl terephthalate, 39 parts of dimethyl isophthalate, 40 parts of ethylene glycol, 29 parts The isosorbide of 25 parts, the glucosamine of 25 parts, the zinc acetate of 0.03 part and 0.02 part of 2,6-di-tert-butyl-4-methylphenol are put into reaction bottle, start heating, stirring rate 300r / min, temperature rises Keep warm for 45 minutes at 175°C, then raise the temperature to 195°C, react for 120 minutes, and protect the whole process with nitrogen gas, the unit is parts by mass;

[0033] (2) Add 0.03 parts of ethylene glycol antimony, raise the temperature to 275°C, gradually reduce the pressure in the reactor until the residual pressure is 0.5kPa, and the reaction time is 100 minutes;

[0034] (3) be heated up to 285 ℃, gradually reduce the pressure in the reactor u...

Embodiment 3

[0038] (I) Group distribution ratio

[0039]

[0040] (II) preparation steps:

[0041] (1) exhaust the air in the polyester reaction device with nitrogen, under the protection of nitrogen, 155 parts of dimethyl terephthalate, 39 parts of dimethyl isophthalate, 50 parts of ethylene glycol, 15 parts The propylene glycol of 29 parts, the isosorbide of 29 parts, the glucosamine of 55 parts, the esterification catalyst of 0.08 part and 0.05 part of 2,6-di-tert-butyl-4-methylphenol are put into reaction bottle, start heating, stir The speed is 300r / min, when the temperature rises to 165°C, it is kept for 40 minutes, then the temperature is raised to 190°C, and the reaction is carried out for 90 minutes. The whole process is protected by nitrogen gas, and the unit is parts by mass;

[0042] (2) Add 0.08 parts of polycondensation catalyst, raise the temperature to 270°C, gradually reduce the pressure in the reactor until the residual pressure is 0.80kPa, and the reaction time is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com