A weather-resistant adhesive and its application on solar cell backplanes

A technology of solar cells and adhesives, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of poor initial adhesion of the backsheet, and achieve guaranteed service life, heat resistance and yellowing resistance Excellent, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

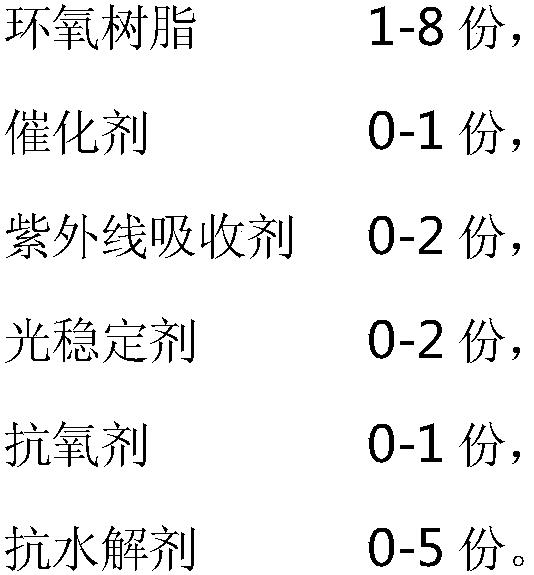

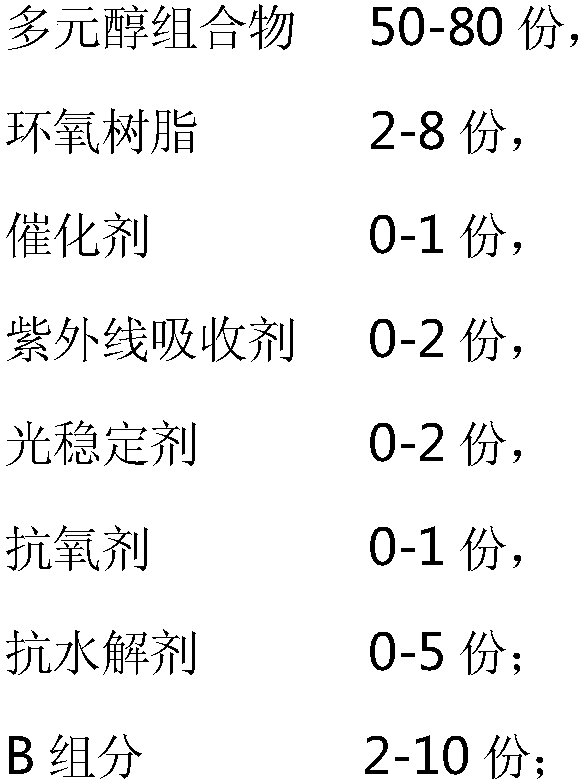

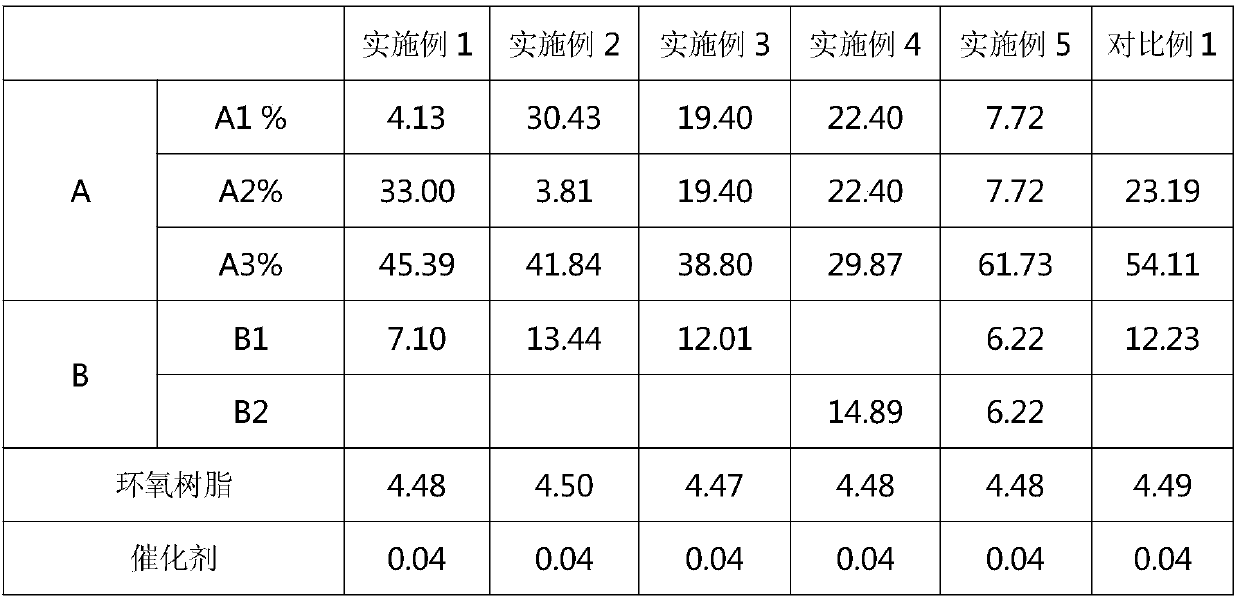

[0067] Component A includes polyether polyol A1, which is polyoxypropylene glycol, its molecular weight is 1000, and its hydroxyl value is 50 mgKOH / g. The amount accounts for 5% of the total amount of the polyol composition, 4.13 g in total;

[0068] Polyester polyol A2, obtained by polycondensation of phthalic anhydride and 2-butyl-2-ethyl-1,3-propanediol, has a molecular weight of 8000, a hydroxyl value of 20 mgKOH / g, and the dosage accounts for 40% of the total amount, a total of 33.00g;

[0069] Acrylate polyol A3, an acrylate polyol obtained by copolymerization of methyl methacrylate, butyl acrylate, butyl methacrylate and 2-hydroxyethyl methacrylate, has a molecular weight of 100,000 and a hydroxyl value of 15 mgKOH / g, the amount accounts for 55% of the total amount of the polyol composition, a total of 45.39g.

[0070] Component B is aliphatic isocyanate B1, 1,6-diisocyanatohexane, 7.10g.

[0071] Auxiliary agent is bisphenol A glycidyl ether epoxy resin, 4.48g, cata...

Embodiment 2

[0076] A component comprises polyether polyol A1, is polytetrahydrofuran, and its molecular weight is 8000, and hydroxyl value is 20mgKOH / g, and consumption accounts for 40% of polyol composition total amount, altogether 30.43g; Polyester polyol A2, by ophthalmic Prepared by polycondensation of phthalic anhydride and 2,4-dibutyl-1,5-pentanediol, its molecular weight is 1000, and its hydroxyl value is 60mgKOH / g. g; Acrylate polyol A3, an acrylate polyol obtained using butyl acrylate, cyclohexyl methacrylate, 2-hydroxyethyl methacrylate and butyl methacrylate, has a molecular weight of 5000 and a hydroxyl value of 50mgKOH / g, the dosage accounts for 55% of the total amount of the polyol composition, 41.84g in total.

[0077] Component B is aliphatic isocyanate B1, 1,6-diisocyanatohexane, 13.44g.

[0078] Other additives include epoxy resin bisphenol A glycidyl ether, 4.5g, catalyst is dibutyltin dilaurate, 0.04g, coupling agent is vinyltrialkoxysilane, 0.91g, and ultraviolet abs...

Embodiment 3

[0083]Component A includes polyether polyol A1, which is polyoxyethylene glycol, its molecular weight is 3000, and its hydroxyl value is 30 mgKOH / g. Alcohol A2, obtained by polycondensation of 2-methylsuccinic acid and 3,3-dimethyl-1,5-pentanediol, has a molecular weight of 2000 and a hydroxyl value of 45 mgKOH / g, and its dosage accounts for the total polyol composition 25% of the amount, a total of 19.40g; Acrylate polyol A3 is (meth)acrylic acid-2-hydroxypropyl ester homopolymer, its molecular weight is 50000, and the hydroxyl value is 30mgKOH / g, and the consumption accounts for the total polyol composition 50% of the amount, a total of 38.80g.

[0084] Component B is aliphatic isocyanate B1, 1,6-diisocyanatohexane, 12.01g.

[0085] Other additives include epoxy resin bisphenol A glycidyl ether, 4.47g, catalyst is dibutyltin dilaurate, 0.04g, coupling agent is vinyltrialkoxysilane, 0.89g, and ultraviolet absorber is TINUVIN571 , 0.56g, light stabilizer is TINUVIN765, 0.56g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com