Epoxy anti-corrosive paint for underwater construction and preparation method

An epoxy anti-corrosion coating and underwater construction technology, applied in anti-corrosion coatings, epoxy resin coatings, antifouling/underwater coatings, etc., can solve the problems of coating loss, difficult underwater concrete surface coating, etc., and achieve construction curing Fast, conducive to construction and brushing, and the effect of improving sag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

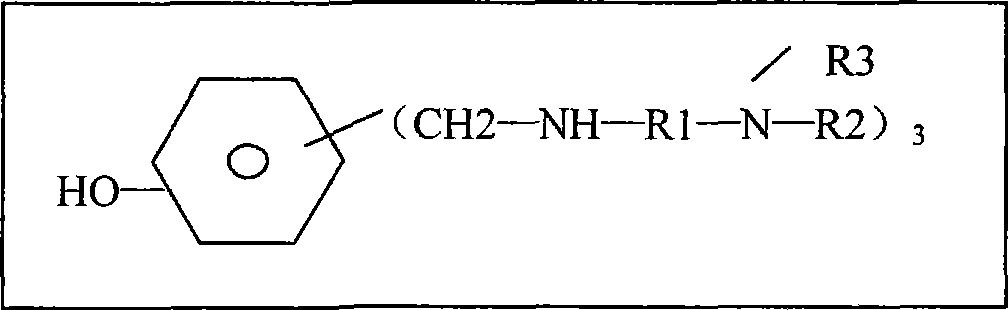

Embodiment 1

[0020] Embodiment 1: 25wt% liquid epoxy resin 618, 1wt% glycidyl ether epoxy reactive diluent AGE, 23wt% 800 mesh barite powder, 22wt% titanium dioxide, 0.5wt% modified polyamide thixotropic agent CRAYVALLEC ULTRA, 0.5wt% dispersant DISPERBYK163, 0.2wt% defoamer BYK066N, 3wt% coupling agent SILANE A187, after mixing, disperse at high speed and keep warm at 60-65°C for 1 hour to obtain A with a viscosity of about 60000cP at 25°C and a specific gravity of about 2.0 Component. 17wt% band C9 hydrocarbon chain Mannich epoxy curing agent D0964 (produced by Shanghai Duer Chemical Co., Ltd., the same below), 8wt% reactive accelerator 2,4,6-tri-dialkylaminoalkylamine Methyl phenol D0592 (produced by Shanghai Duer Chemical Co., Ltd., the same below), mixed to obtain component B. Mix components A and B, and under the condition of water velocity of about 1.0 m / s, it can be smoothly applied on the underwater concrete surface without falling off, and the bonding strength can reach 1MPa aft...

Embodiment 2

[0021] Embodiment 2: 20wt% liquid epoxy resin 6101, 5wt% glycidyl ether epoxy reactive diluent 501, 21wt% 400 mesh barite powder, 29wt% titanium dioxide, 1.2wt% modified polyamide thixotropic agent CRAYVALLEC ULTRA, 0.2wt% dispersant DISPERBYK163, 0.4wt% defoamer BYK066N, 2wt% coupling agent SILANE A187, mixed at high speed and kept at 60-65°C for 1 hour to obtain 25°C viscosity about 100000cP, specific gravity about 1.8 A component. Mix 18wt% Mannich epoxy curing agent D0963 with C15 hydrocarbon chain and 2wt% reactive accelerator 2,4,6-tri-dialkylaminoalkylamine methylphenol D0592 to prepare component B. Mix components A and B, and under the condition of water velocity of about 1.0 m / s, it can be smoothly applied on the underwater concrete surface without falling off, and the bonding strength can reach 1MPa after 24 hours.

Embodiment 3

[0022] Embodiment 3: 14wt% liquid epoxy resin 6101, 14wt% liquid epoxy resin 618, 4wt% glycidyl ether epoxy reactive diluent 501, 20wt% barite powder 400 orders, 17wt% titanium dioxide, 1.5wt% modification Polyamide thixotropic agent CRAYVALLEC ULTRA, 0.5wt% dispersant DISPERBYK163, 0.5wt% defoamer BYK066N, 0.5wt% coupling agent SILANE A187, after mixing, disperse at high speed and keep warm at 60-65°C for 1 hour to obtain 25°C viscosity About 100000cP, A component with a specific gravity of about 2.1. Mix 15wt% Mannich epoxy curing agent D0964 with C9 hydrocarbon chain and 3wt% reactive accelerator 2,4,6-tri-dialkylaminoalkylamine methylphenol D0592 to prepare component B. Mix components A and B, and under the condition of water velocity of about 1.0 m / s, it can be smoothly applied on the underwater concrete surface without falling off, and the bonding strength can reach 1MPa after 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com