Preparation method of bacterial cellulose/functional nanometer particle composite film

A bacterial cellulose and functional nanotechnology, applied in the field of composite materials, can solve the problems of destroying the natural three-dimensional network structure of bacterial cellulose, the inability to directly compound nanoparticles, and the inability to exert excellent properties, etc., to achieve the effect of expanding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention discloses a preparation method of bacterial cellulose / functional nanoparticle composite film, comprising the following steps:

[0027] A), inoculating the bacterial species onto a solid substrate, and forming a cellulose film on the surface of the solid substrate after fermentation;

[0028] B), adding a nutrient solution and a source of functional nanoparticles to the surface of the cellulose membrane, and fermenting;

[0029] C), repeat step B), and obtain bacterial cellulose / functional nanoparticle composite film after culturing.

[0030] In the invention, bacteria are inoculated onto a solid substrate, and nutrient solution and functional nanoparticle sources are added repeatedly during the growth of bacteria, and continuous fermentation is performed to obtain a bacterial cellulose / functional nanoparticle composite membrane.

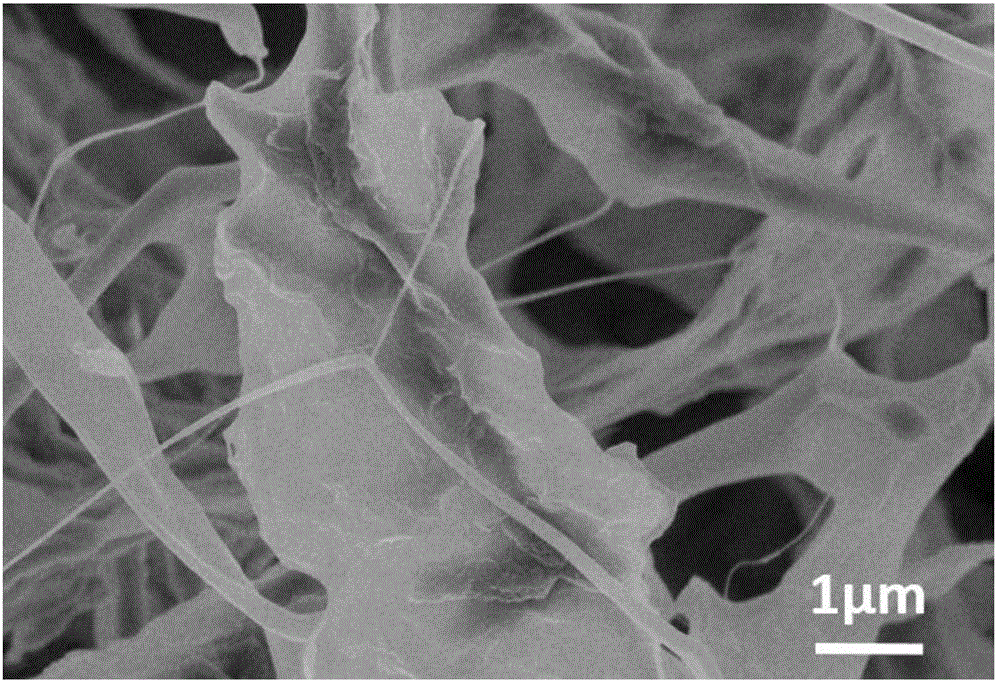

[0031] In the process of preparing the bacterial cellulose / functional nanoparticle composite membran...

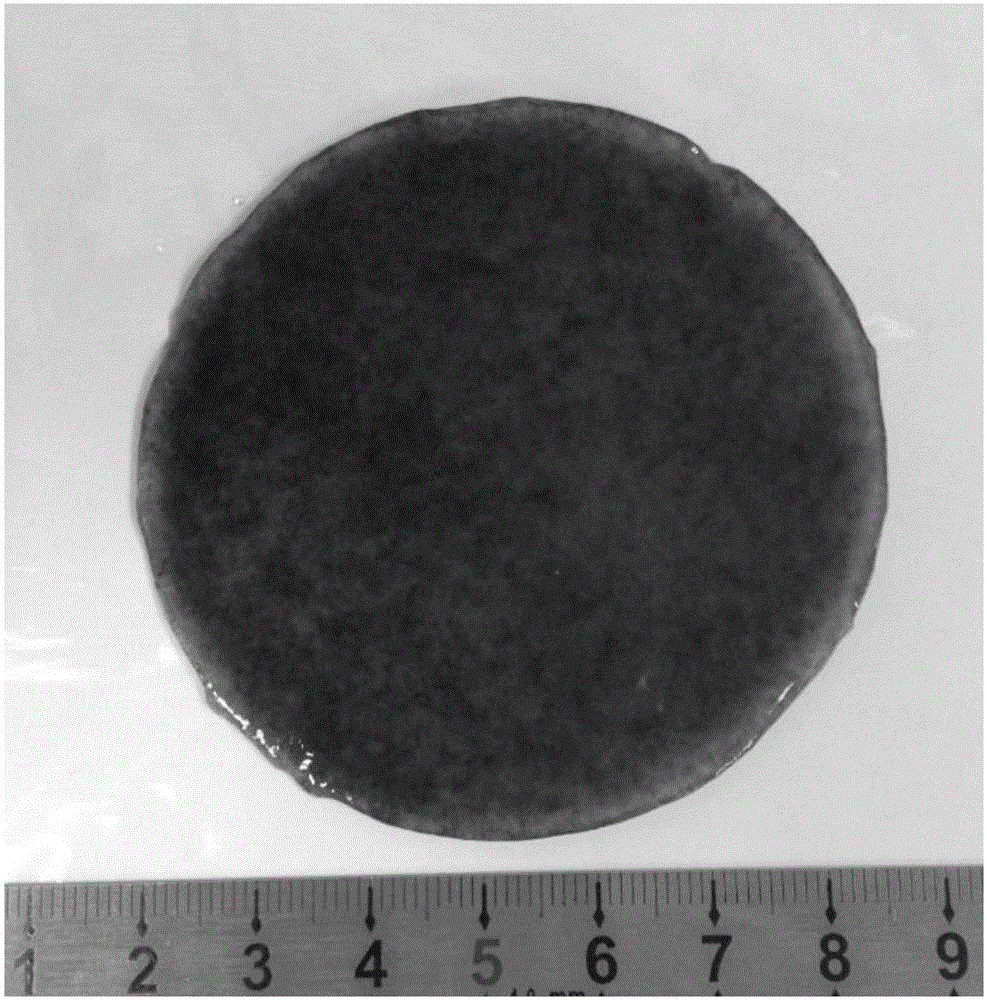

Embodiment 1

[0045] Prepare 500mL aqueous solution containing 10wt% glucose, 1wt% yeast powder, 2wt% calcium carbonate, and 1.5wt% agar, stir to dissolve and boil, divide into five 250mL beakers, seal the beakers with tissue culture film, and autoclave Sterilize the pot, cool and stand to obtain a plane; prepare an aqueous solution containing 5wt% glucose and 1wt% yeast powder; use sterile water to prepare a 1mg / mL graphene oxide solution;

[0046] Inoculate the strain of Gluconacetobacter xylinum on the above-mentioned flat medium, put it into an incubator, and cultivate it at 28°C for 36h;

[0047] Transfer the beaker from a constant temperature incubator to a sterile table, add 0.5mL of nutrient solution with a pipette gun, shake gently to spread evenly, and add 0.4mL of the above graphene oxide aqueous solution with a pipette gun, shake gently to spread evenly, and transfer to a constant temperature Incubator; repeat the above operation once every 8 hours, and cultivate for 10 days;

...

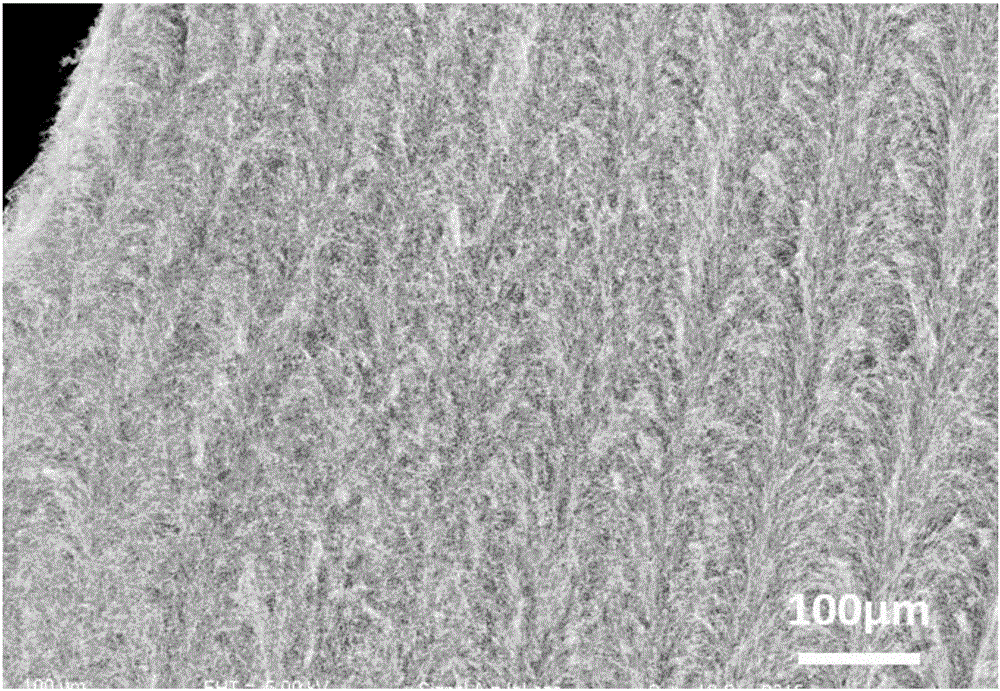

Embodiment 2

[0053] Prepare 500mL aqueous solution containing 10wt% glucose, 1wt% yeast powder, 2wt% calcium carbonate, and 1.5wt% agar, stir to dissolve and boil, divide into five 250mL beakers, seal the beakers with tissue culture film, and autoclave Sterilize, cool and stand to obtain a plane; prepare an aqueous solution containing 5wt% glucose and 1wt% yeast powder; prepare a 2mg / mL carbon nanotube solution and sterilize it with an autoclave;

[0054] Inoculate the Gluconacetobacter xylinum species on the above-mentioned plane medium, put it into an incubator, and cultivate it at 28°C for 36h;

[0055] Transfer the beaker from the constant temperature incubator to the sterile table, add 0.5mL of nutrient solution with a pipette gun, shake gently to spread evenly, and add 0.4mL of the above carbon nanotube aqueous solution with a pipette gun, shake gently to spread evenly, and transfer to constant temperature Incubator; repeat the above operation once every 8 hours, and cultivate for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com