Instant potato rice flour and processing method thereof

A processing method, the technology of whole potato powder, applied in the field of food processing, can solve the problems of single raw material, complex production process, high technical difficulty, etc., and achieve the effect of simple process, good taste and increased consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

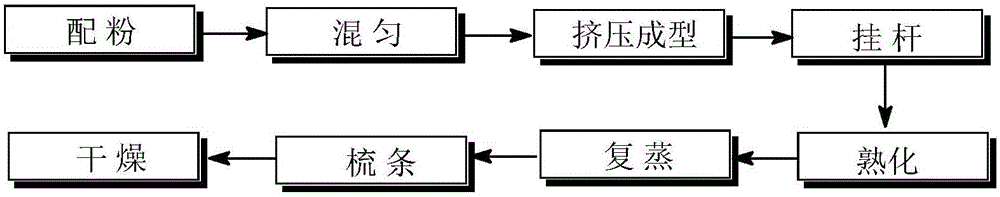

Method used

Image

Examples

Embodiment 1

[0035] 1) compound powder

[0036] According to parts by weight, the whole potato flour: 35 parts, the early indica rice flour: 25 parts, the potato starch: 25 parts, the isoamylase: 0.2 part, the compound phosphate: 0.3 part are mixed and stirred evenly;

[0037] 2) Kneading

[0038] Add water to the flour prepared in step 1, and stir it into dough at the same time, so that the water content of the prepared dough is not less than 25%;

[0039] 3) The first ripening

[0040] Place the dough prepared in step 2 in a curing machine for curing, the time is 15 minutes, and the temperature is 35°C;

[0041] 4) Extrusion

[0042] The cooked dough is extruded, and the diameter of the extruded rice flour is: 0.6mm;

[0043] 5) Hanging rod

[0044] Hang the extruded rice noodles on the hanging rod;

[0045] 6) The second ripening

[0046] Hang the rice noodles on the rods one by one in the curing room for curing. The curing time is 5 hours and the humidity is 70%;

[0047] 7) Re...

Embodiment 2

[0060] 1) Mixing powder

[0061] According to parts by weight, the whole potato flour: 55 parts, the early indica rice flour: 25 parts, the cornstarch: 35 parts, the isoamylase: 0.4 part, the compound phosphate: 0.5 part are mixed and stirred evenly;

[0062] 2) Kneading

[0063] Add water to the flour prepared in step 1, and stir it into dough at the same time, so that the water content of the prepared dough is not less than 30%;

[0064] 3) The first ripening

[0065] Place the dough prepared in step 2 in a curing machine for curing, the time is 20 minutes, and the temperature is 40°C;

[0066] 4) Extrusion

[0067] The cooked dough is extruded, and the diameter of the extruded rice flour is: 1.0mm;

[0068] 5) Hanging rod

[0069] Hang the extruded rice noodles on the hanging rod;

[0070] 6) The second ripening

[0071] Hang the rice noodles on the hanging rods one by one in the curing room for curing. The curing time is 6 hours and the humidity is 80%;

[0072] 7)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com