Burn dressing applicable to department of burn and having antibacterial effect

A technology of fruit acid and sodium ascorbyl phosphate, which is applied in medical science, bandages, absorbent pads, etc., can solve the problems of not being able to inhibit bacteria, wound infection, skin irritation, etc., so as to improve the recovery effect, promote absorption, and accelerate Recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

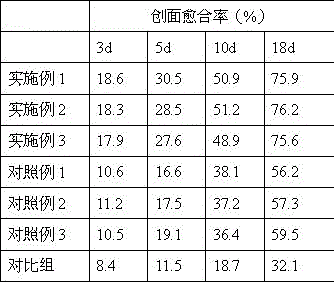

Examples

Embodiment 1

[0023] Step 1, in parts by weight, add 15 parts of glycerin to 3 parts of alginate, 4 parts of glycolic acid, 10 parts of vitamin E, 2 parts of sodium ascorbyl phosphate, and 3 parts of sodium polyacrylate, and stir evenly to obtain a mixed solution ;

[0024] Step 2, in parts by weight, take 30 parts of purslane, 30 parts of astragalus, and 20 parts of honeysuckle, mix them, add 200 parts of water, extract at 40°C for 0.5 hours, and filter to obtain the extract;

[0025] The 3rd step, by weight, after pulverizing 1 part of bamboo fiber, mix with 5 parts of 1.0mol / L hydrochloric acid solution, heat and carry out hydrolysis reaction, after reaction finishes, filter out residue, residue is washed with water to pH neutrality, Then the residue, 0.2 parts of polyethylene glycol, and 5 parts of water were mixed evenly, and the temperature was raised to 80°C for reaction to obtain a white slurry, which was spray-dried to obtain modified microcrystalline cellulose;

[0026] Step 4, b...

Embodiment 2

[0029] Step 1, in parts by weight, add 30 parts of glycerin to 5 parts of alginate, 6 parts of glycolic acid, 15 parts of vitamin E, 4 parts of sodium ascorbyl phosphate, and 5 parts of sodium polyacrylate, and stir evenly to obtain a mixed solution ;

[0030] Step 2, in parts by weight, take 50 parts of purslane, 60 parts of astragalus, and 30 parts of honeysuckle, mix them, add 400 parts of water, extract at 60° C. for 1 hour, and filter to obtain the extract;

[0031] The 3rd step, by weight, after pulverizing 2 parts of bamboo fiber, mix with 20 parts of 1.0mol / L hydrochloric acid solution, heat and carry out hydrolysis reaction, after reaction finishes, filter out residue, residue is washed with water to pH neutrality, Then, mix the residue, 0.4 parts of polyethylene glycol, and 8 parts of water evenly, and heat up to 90°C to react to obtain a white slurry, which is spray-dried to obtain modified microcrystalline cellulose;

[0032] Step 4, in parts by weight, dissolve 6...

Embodiment 3

[0035] Step 1, in parts by weight, add 20 parts of glycerin to 4 parts of alginate, 5 parts of glycolic acid, 12 parts of vitamin E, 3 parts of sodium ascorbyl phosphate, and 4 parts of sodium polyacrylate, and stir evenly to obtain a mixed solution ;

[0036] Step 2, in parts by weight, take 40 parts of purslane, 50 parts of astragalus, and 25 parts of honeysuckle, mix them, add 300 parts of water, extract at 50°C for 0.8 hours, and filter to obtain the extract;

[0037] The 3rd step, by weight, after pulverizing 2 parts of bamboo fiber, mix with 12 parts of 1.0mol / L hydrochloric acid solution, heat and carry out hydrolysis reaction, after reaction finishes, filter out residue, wash residue with water to pH neutrality, Then, mix the residue, 0.3 parts of polyethylene glycol, and 7 parts of water evenly, and heat up to 85°C to react to obtain a white slurry, which is spray-dried to obtain modified microcrystalline cellulose;

[0038] Step 4, in parts by weight, dissolve 5 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com