Flame-retardant cable material

A flame-retardant cable, aluminum hydroxide flame retardant technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of poor compatibility of basic resins, lower mechanical properties of cable materials, etc., and achieve temperature resistance The effect of high grade, low cost and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

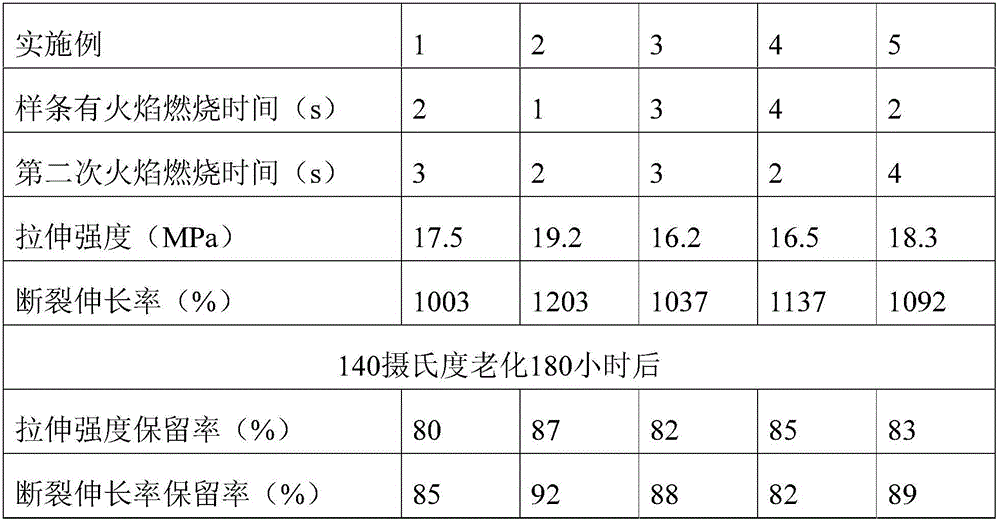

Examples

Embodiment Construction

[0021] Now with regard to the technical scheme provided by the application and the effects and advantages that can be produced, a preferred embodiment of the application is described in detail as follows:

[0022] The invention provides a flame-retardant cable material, which comprises the following components in parts by mass:

[0023] 80-100 parts of low-density polyethylene resin, 40-60 parts of PVC resin, 50-60 parts of aluminum hydroxide flame retardant, 1-2 parts of coupling agent, 6-8 parts of melamine cyanurate, dimethyl di 2-3 parts of sulfur, 6-10 parts of dioctyl phthalate, 0.1-0.3 parts of ultraviolet absorber, 10-15 parts of active nano-calcium carbonate, 4-6 parts of paraffin, 0.2-0.4 parts of stearic acid, cyclic Oxygenated soybean oil 2-4 parts.

[0024] During specific implementation, the following weight components can be set respectively: 80 parts of low-density polyethylene resin, 40 parts of PVC resin, 50 parts of aluminum hydroxide flame retardant, 1 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com