Separation method of impurities in angiotensin receptor antagonist and NEP inhibitor compound

A receptor antagonist, angiotensin technology, applied in the field of separation of impurities in complexes, achieves the effect of simple process, accurate and reliable separation method and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

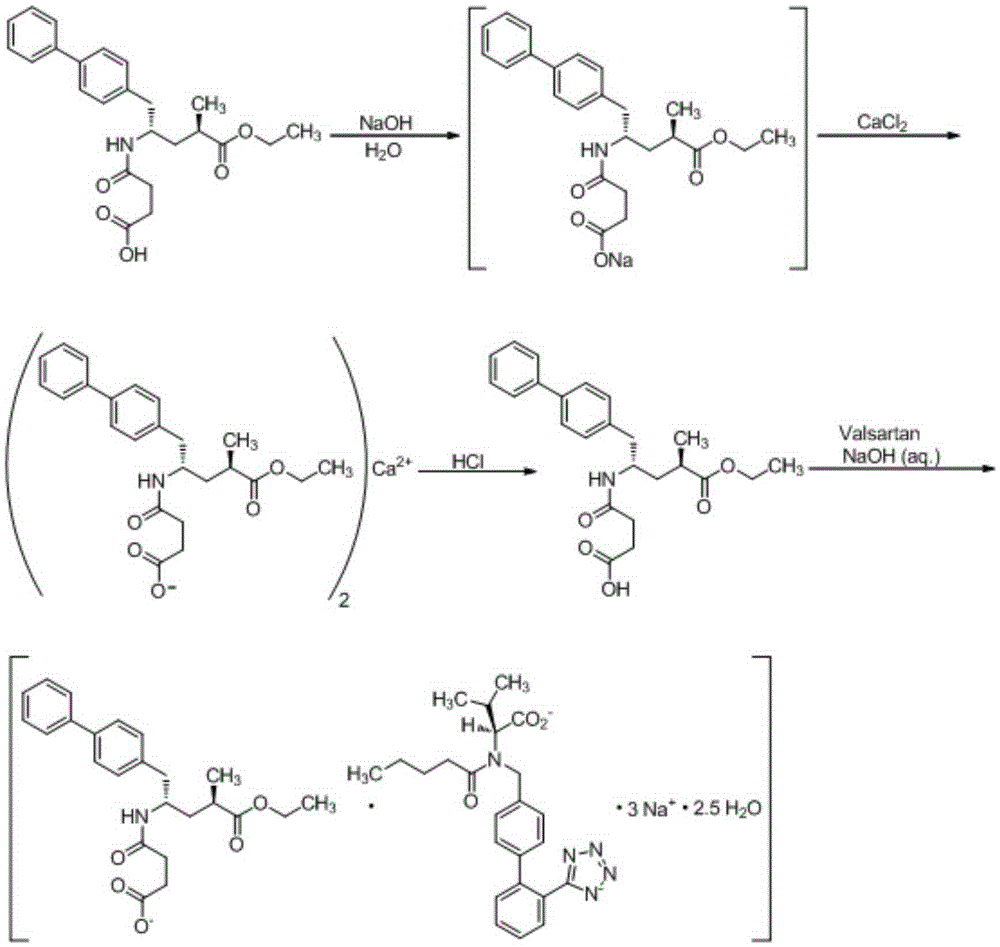

[0090] according to figure 1 The flow chart shown is to prepare a complex of angiotensin receptor antagonist and NEP inhibitor, figure 1 This is a flow chart of the preparation process of the complex of angiotensin receptor antagonist and NEP inhibitor provided in Example 1 of the present invention:

[0091] The compound having the structure shown in Formula 4 is a commercially available product.

[0092] 10g of the compound having the structure represented by formula 4 and 1.9g of sodium hydroxide are reacted in water at 20-30°C for 1 hour to obtain the compound having the structure represented by formula 3;

[0093] 10 g of the compound having the structure shown in Formula 3 and 2.6 g of calcium chloride are reacted at 60 to 70° C. for 2 hours to obtain the compound having the structure shown in Formula 2;

[0094] 15 g of the compound having the structure shown in formula 2 and 52 g of 1N hydrochloric acid were reacted at 20-30° C. for 2 hours to obtain the compound having the stru...

Embodiment 2

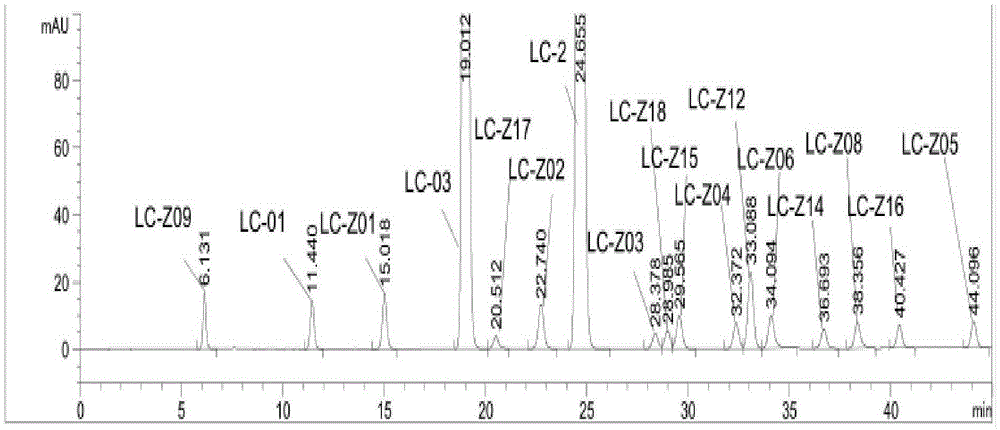

[0098] The complex of angiotensin receptor antagonist and NEP inhibitor prepared in Example 1 of the present invention was used for impurity separation by high performance liquid chromatography. The column filler in the high performance liquid chromatography was octadecyl Silane-bonded silica gel, the mobile phase includes a phosphate buffer (aqueous phase) with a molar concentration of 35mmol / L and a mixture of acetonitrile and methanol (organic phase) with a volume ratio of 55:45, phosphate buffer and acetonitrile and methanol The initial volume ratio of the mixed solution is 50:50, the flow rate of the mobile phase is 1mL / min, the column temperature is 35°C, and the detection wavelength is 250nm; the gradient elution method is used to make the mobile phase pass through the chromatographic column. The method is specifically as follows: in 0-35min, the volume content of the water phase in the mobile phase is reduced from 50% to 10%, and the volume content of the organic phase i...

Embodiment 3

[0110] The complex of angiotensin receptor antagonist and NEP inhibitor prepared in Example 1 of the present invention was used for impurity separation by high performance liquid chromatography. The column filler in the high performance liquid chromatography was octadecyl Silane-bonded silica gel. The mobile phase includes a 0.1% aqueous solution of trifluoroacetic acid (aqueous phase) and a mixture of acetonitrile and methanol (organic phase) with a mass ratio of 50:50, trifluoroacetic acid aqueous solution and acetonitrile and methanol The initial volume ratio of the mixed solution is 55:45, the flow rate of the mobile phase is 0.8mL / min, the column temperature is 25°C, and the detection wavelength is 250nm; the gradient elution method is used to make the mobile phase pass through the chromatographic column. The specific method is as follows: at 0~35min, the volume content of the water phase in the mobile phase is reduced from 55% to 5%, and the volume content of the organic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com