Treatment process for wastewater from synthetic leather production

A technology for production of wastewater and treatment process, applied in biological water/sewage treatment, animal processing wastewater treatment, water treatment parameter control, etc., can solve problems such as impact, environmental problems, unsatisfactory treatment effect, etc. Effects of Bad Odor Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

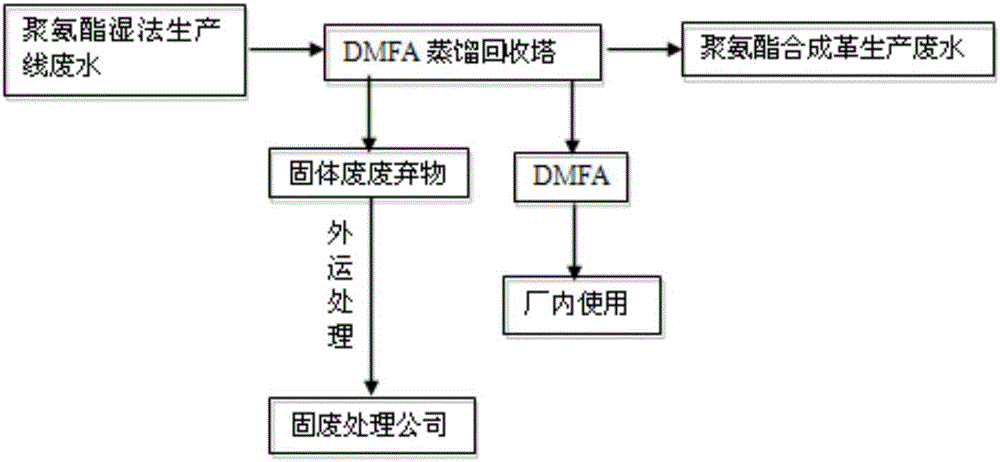

[0052] refer to figure 1 The DMF distillation recovery tower is used to recover the DMF in the wastewater of the polyurethane wet process production line. The purity of the recovered DMF can reach 99.9%, and the recovery rate can reach 99.5%. The recovered DMF can be used continuously in the factory, and the solid waste generated is transported outside After being treated by the solid waste treatment company, the wastewater produced is wastewater from the production of polyurethane synthetic leather. The temperature of the wastewater reaches 50-90°C. The water quality indicators are shown in the following table:

[0053] pH

CODcr

BOD5

SS

animal and vegetable oil

total ammonia

Chroma

5.93

29259.9

415

263

12.1

68

128

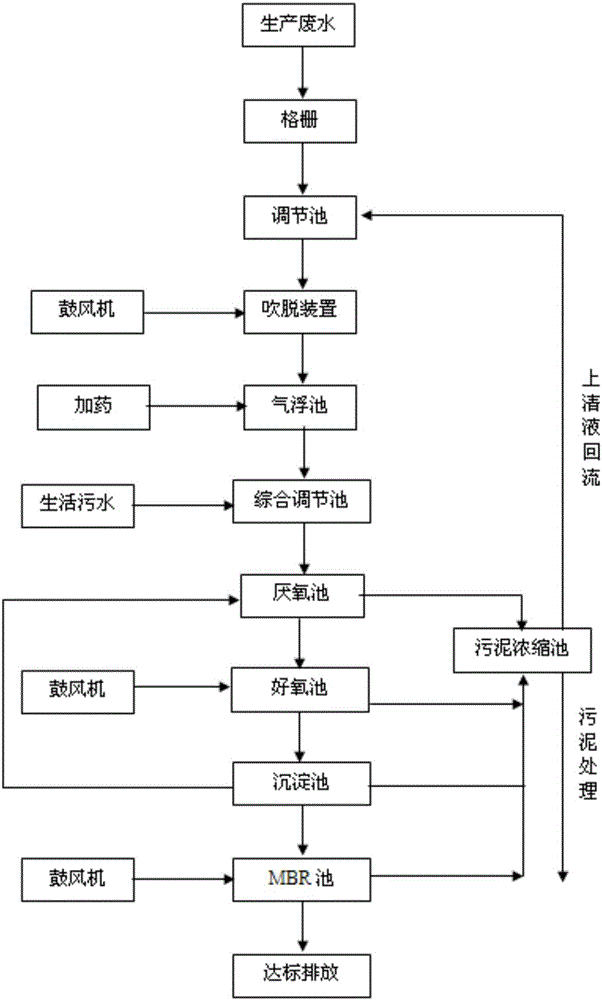

[0054] This embodiment adopts as figure 2 The treatment process and the treatment system treat the waste water. The treatment system of the present invention includes a grid, a regulating tank, a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com