Preparation method of 3,4-cyclopentyl-1-tetralone

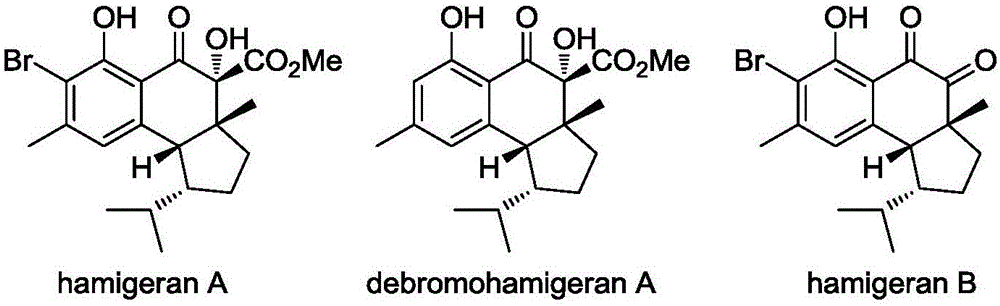

A technology of tetralinone and cyclopentyl, which is applied in the field of preparation of 3,4-cyclopentyl-1-tetralinone, can solve rare problems and the like, achieves simple operation, excellent yield and good product selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

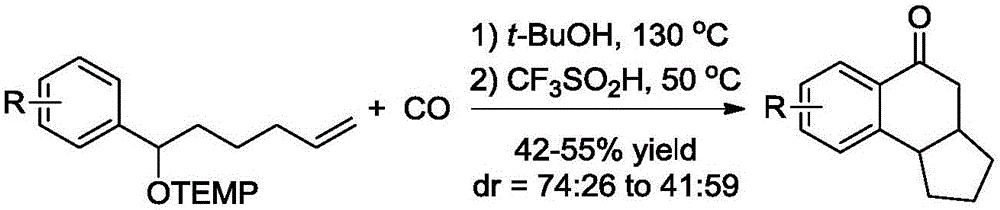

Method used

Image

Examples

Embodiment 1

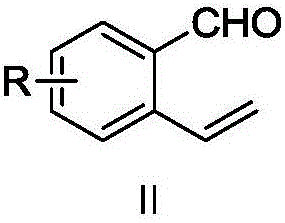

[0028] Take a dry Sri Lankan reaction tube, weigh into CuBr 2 (8.8mg, 0.040mmol), potassium carbonate (33.1mg, 0.24mmol), diethyl azodicarboxylate (13.9mg, 0.080mmol), and the ligand pentamethyldiethylenetriamine (13.8mg, 0.080 mmol), vacuumize and change nitrogen, replace three times, then add the raw material 2-vinylbenzaldehyde 1a (31.7mg, 0.24mmol) and 2-phenylallyl-2 bromopropanediol dissolved in 5mL dimethyl sulfoxide Acid diethyl ester 2a (70.8 mg, 0.20 mmol). After the reaction was stirred at room temperature for 12 h, it was quenched by adding 10 mL of water, extracted three times with ethyl acetate (10 mL), combined, the organic phase was washed with saturated edible water, and dried over anhydrous sodium sulfate. The organic phase was concentrated and separated by silica gel (300-400 mesh) column chromatography (eluent: petroleum ether / ethyl acetate volume ratio: 15 / 1) to obtain 65 mg of white solid product 3aa, yield 80%. The melting point of the product is 111-1...

Embodiment 2

[0032] Except that the alkenylbenzaldehyde shown in the structural formula 1a was used to replace the alkenylbenzaldehyde shown in the structural formula 1a in Example 1, the remaining operating steps were the same as in Example 1. The yield: 79%, a colorless liquid. 1 H NMR (600MHz, CDCl 3 ):δ7.49–7.45(m,1H),7.37–7.33(m,2H),7.30–7.23(m,2H),7.20–7.16(m,2H),7.14–7.10(m,1H),4.24 –4.13(m,4H),3.82(s,3H),3.79(d,J=11.6Hz,1H),3.55–3.48(m,1H),3.12–3.04(m,1H),2.92–2.85(m ,1H),2.60–2.53(m,1H),2.47–2.41(m,1H),2.30–2.24(m,1H),1.25(t,J=7.1Hz,3H),1.20(t,J=7.1 Hz,3H); 13 C NMR (151MHz, CDCl 3 ): δ197.5, 172.3, 172.2, 158.6, 138.2, 135.5, 132.5, 130.3, 129.5, 128.5, 127.0, 122.1, 109.6, 61.7, 59.5, 55.4, 54.7, 45.6, 41.6, 41.0, 38.0, 14.0; ESI) calcd for C 26 h 29 o 6 (M+H) + 437.1964, found 437.1956.

[0033] The reaction formula is as follows:

[0034]

Embodiment 3

[0036] Except that the alkenyl benzaldehyde shown in the structural formula 1c is used to replace the alkenyl benzaldehyde shown in the structural formula 1a in Example 1, the remaining operating steps are the same as in Example 1, the yield: 80%, white solid, melting point: 155-157 ° C ; 1 H NMR (600MHz, CDCl 3 ):δ7.44–7.40(m,1H),7.36–7.27(m,3H),7.19–7.15(m,2H),6.73(s,1H),6.01(s,2H),4.23–4.15(m ,4H),3.73(d,J=11.6Hz,1H),3.50–3.40(m,1H),3.07–2.99(m,1H),2.90–2.85(m,1H),2.58–2.51(m,1H ),2.44–2.38(m,1H),2.30–2.25(m,1H),1.25(t,J=7.0Hz,3H),1.22(t,J=7.1Hz,3H); 13 C NMR (151MHz, CDCl 3): δ195.8, 172.3, 172.1, 152.5, 147.3, 139.7, 138.4, 129.5, 128.5, 127.0, 126.5, 108.0, 106.6, 101.7, 61.7, 61.7, 59.3, 54.3, 45.6, 42.6, 40.9, 38.3 HR ESI) calcd for C 26 h 27 o 7 (M+H) + 451.1757,found 451.1753.

[0037] The reaction formula is as follows:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com