Methanol-to-gasoline combined technology

A methanol-to-gasoline and combined process technology is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, and biological raw materials. rate, the effect of increasing the octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

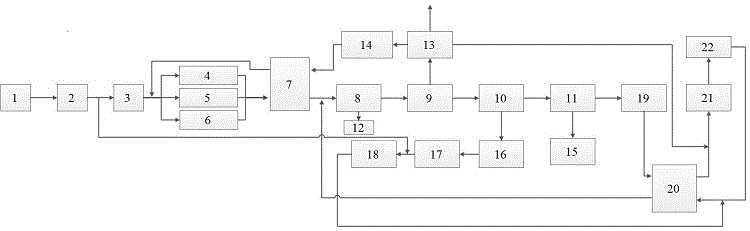

[0023] The embodiment of the scheme is described in combination with the process flow chart to further illustrate the present invention.

[0024]The methanol raw material 1 is pumped into the heating furnace 2, and part of the methanol vapor from the heating furnace 2 enters the dimethyl ether reactor 3. The dimethyl ether, water and unreacted methanol from the dimethyl ether reactor 3 enter the gasoline conversion reactors 4, 5 and 6, and the gasoline conversion reactors 4, 5 and 6 are produced by Wuhan Kelin Fine Chemical Co., Ltd. W221A type catalyst. After the product passes through the heat exchanger 7, it enters the oil-water separator 8 for oil-water separation, and the generated water 12 is separated.

[0025] The product after separating the generated water 12 from the oil-water separator 8 enters the deethanizer 9 . The separated dry gas 13 is divided into three parts: one part passes through the compressor 14 and then enters the heat exchanger 7 for preheating, an...

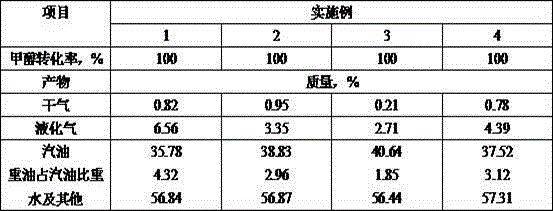

Embodiment example 1

[0029] In the dimethyl ether reactor 3, WD-1 catalyst produced by Wuhan Kelin Fine Chemical Co., Ltd. is used. The hot spot temperature is 260°C and the space velocity is 0.5h. -1 , The operating pressure is 3.0MPa.

[0030] Gasoline conversion reactors 4, 5 and 6 use W221A catalyst produced by Wuhan Kelin Fine Chemical Co., Ltd., the hot spot temperature is 420°C, and the operating pressure is 3.0MPa.

[0031] Part of the separated dry gas 13 passes through the compressor 14 and then enters the heat exchanger 7 for preheating, and then enters the gasoline conversion reactors 4, 5 and 6 with the dimethyl ether, water and unreacted methanol from the dimethyl ether reactor 3 , The dry gas circulation ratio entering the compressor 14 is 1:10.

[0032] The pressure at the top of the deethanizer 9 is 400kPa, and the temperature is 40°C. The pressure at the top of the debutanizer 10 is 1200 kPa, and the temperature is 60°C.

[0033] The liquefied gas 16 exiting the debutanizer 1...

Embodiment example 2

[0039] The WD-1 catalyst produced by Wuhan Kelin Fine Chemical Co., Ltd. is used in the dimethyl ether reactor 3, the hot spot temperature is 280°C, and the space velocity is 1.2h -1 , The operating pressure is 1.8MPa.

[0040] Gasoline conversion reactors 4, 5 and 6 use W221A catalyst produced by Wuhan Kelin Fine Chemical Co., Ltd., with a hot spot temperature of 330°C and an operating pressure of 1.8MPa.

[0041] Part of the separated dry gas 13 passes through the compressor 14 and then enters the heat exchanger 7 for preheating, and then enters the gasoline conversion reactors 4, 5 and 6 with the dimethyl ether, water and unreacted methanol from the dimethyl ether reactor 3 , The dry gas circulation ratio entering the compressor 14 is 15:1.

[0042] The pressure at the top of the deethanizer 9 is 800kPa, and the temperature is 55°C. The pressure at the top of the debutanizer 10 is 400 kPa, and the temperature is 40°C.

[0043] The liquefied gas 16 exiting the debutanize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com