Lactobacillus buchneri inoculant as well as preparation method and application thereof

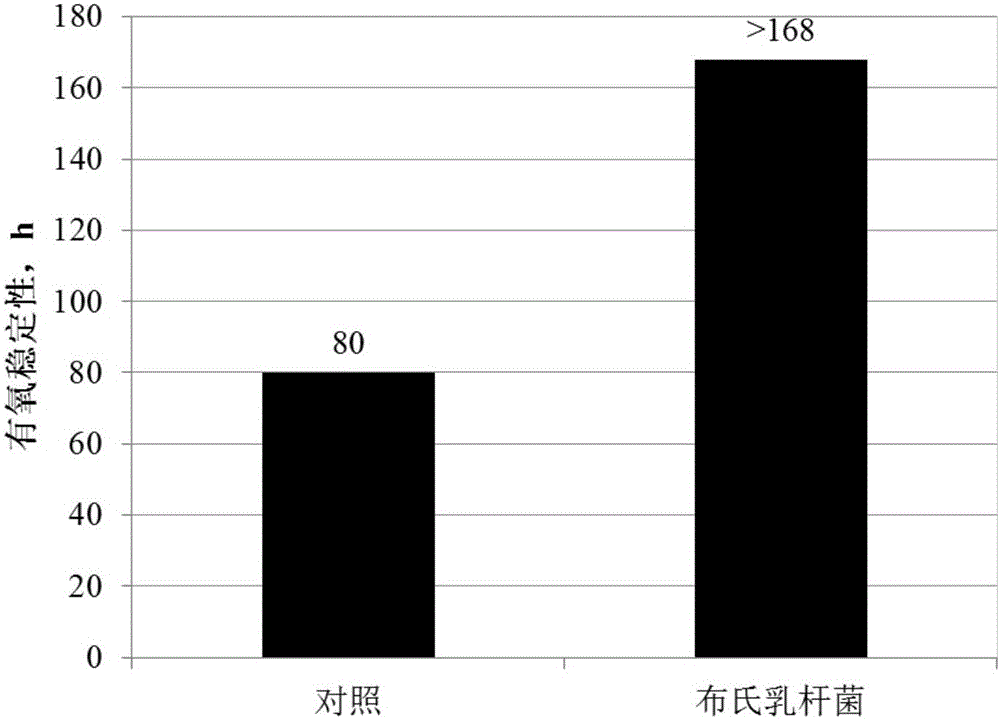

A technology of Lactobacillus brucei and microbial agent, which is applied in the field of Lactobacillus brunii bacterial agent and its preparation, can solve the problems of increasing milk production and adverse effects of aerobic stability, so as to improve performance and improve aerobic stability , the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of Lactobacillus brucei inocula

[0026] (1) Expansion culture of bacteria: inoculate Lactobacillus brucei in the MRS liquid medium, culture for 48 hours at 37°C, and insert the obtained bacterial liquid into the new MRS liquid medium at a ratio of 3%, and expand the culture for 24 hours , Obtain Lactobacillus brucei culture solution;

[0027] (2) Bacterial cell collection: Centrifuge the obtained Lactobacillus brucei culture solution at 8000 rpm for 15 minutes, and wash the obtained Lactobacillus brucei cell with normal saline three times, and finally obtain the cleaned Brinell milk Bacillus cells;

[0028] (3) Preparation of bacterial agent: Add 10% skimmed milk powder to the cleaned Lactobacillus brucei cells, mix well, freeze at -80℃ for 4h; then at a temperature of -50 and a vacuum of ℃ Under the condition of 10Pa, freeze-dry for 36h to obtain Lactobacillus brucei inoculum.

Embodiment 2

[0029] Example 2: Preparation of whole-plant corn silage

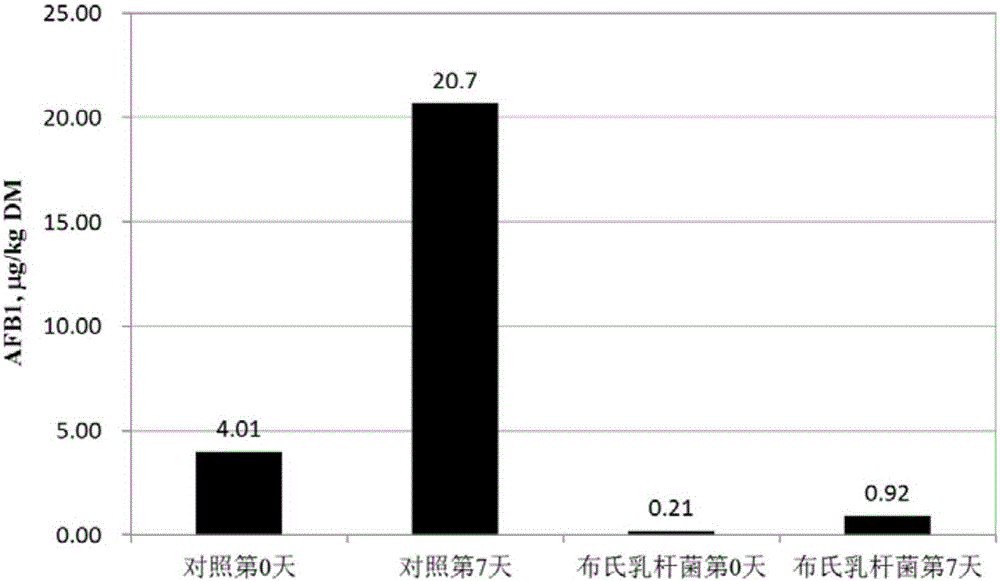

[0030] On the 7th day after half of Jingke 516 silking, 2.1ml of toxin-producing Aspergillus flavus was inoculated on one side of the corn ear, and the number of toxin-producing Aspergillus flavus was 1×10 7 , Purchased from China Collection of Common Microorganisms.

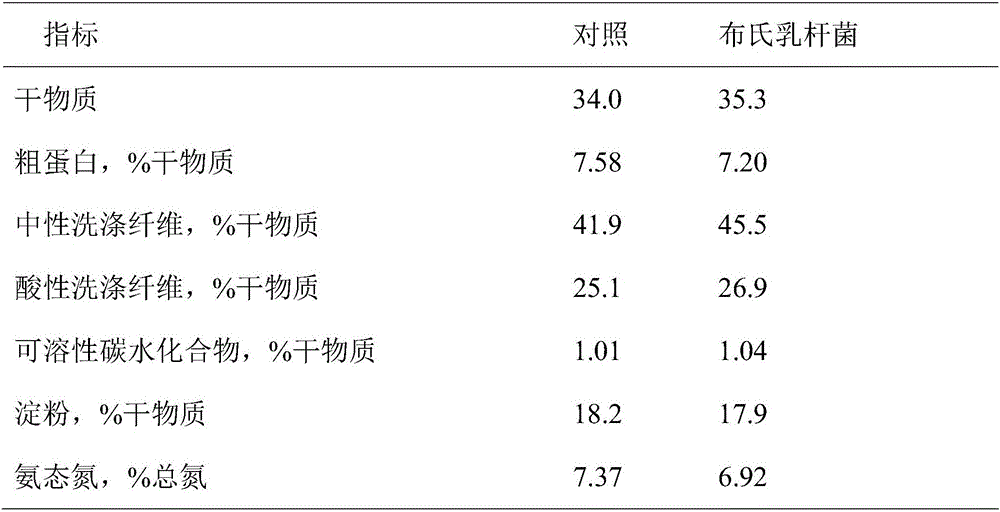

[0031] Cut Jingke 516, which has a moisture content of close to 65% in the wax maturity period, to ensure that the raw materials are clean and free of mold and deterioration, and then cut short to 2-3cm to obtain the silage raw materials; then the diluted Lactobacillus brucei inocula Spray on the silage raw materials and mix evenly, so that each gram of silage raw materials contains 1×10 5 CFU Lactobacillus brucei; finally fill and compact the silage raw materials, pay attention to the corners and surroundings of the silage pit (bucket) during the compaction process to ensure sufficient compaction, and the compaction process is completed within the day of mowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com