Preparation method of biodegradable medical polyurethane and chitosan composite hemostatic sponge

A chitosan and polyurethane technology, applied in application, medical science, drug delivery, etc., can solve the problems of poor degradability, unusable medical field, low biodescriptivity, etc., achieve excellent hemostatic performance, improve hemostatic performance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

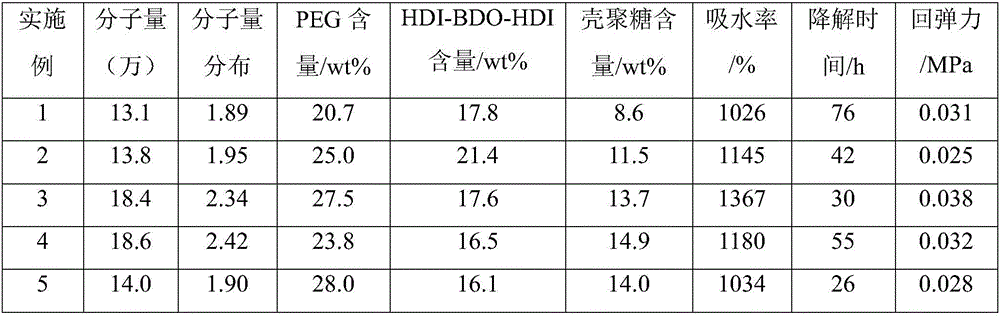

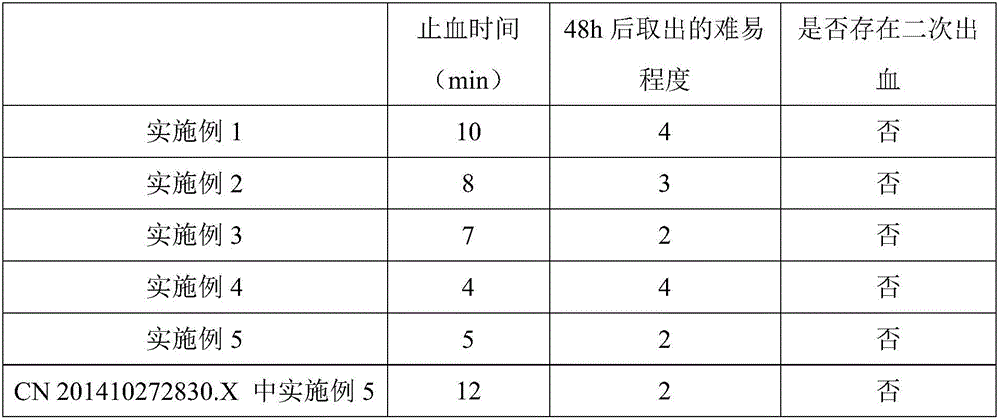

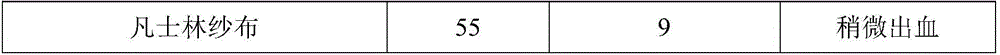

Examples

Embodiment 1

[0058] (1) Synthesis of double-terminated hydroxyl prepolymer

[0059] Put 12g of polyethylene glycol 600 (PEG600, 0.02mol) in a vacuum reaction flask, stir with a magnet, remove water under vacuum (20Pa) at 100°C for 3h, cool to room temperature, and equilibrate with argon. Add 15g D,L-lactide, 15gε-caprolactone and 0.126 stannous octoate (0.3% of raw material mass). Evacuate, balance with argon, repeat three times. Vacuumize to 20Pa, seal the vacuum reaction bottle, heat the oil bath to 120°C, and react for 72h to form a multi-terminated hydroxyl prepolymer.

[0060] (2) Synthesis of double-terminated isocyanate-based prepolymers

[0061] With the double-terminated hydroxyl prepolymer prepared in step 1, connect mechanical stirring, argon protection, heat up to 80 ° C, add chain extender HDI-BDO-HDI dimethyl sulfoxide solution (mass concentration 25%, chain extender According to 1.2 times the molar amount of -NCO / -OH added). Continue the constant temperature reaction at ...

Embodiment 2

[0067] (1) Synthesis of double-terminated hydroxyl prepolymer

[0068] Put 12g of PEG600 (0.02mol) in a vacuum reaction bottle, stir with a magnet, remove water under vacuum (20Pa) at 100°C for 3h, cool to room temperature, and equilibrate with argon. Add 10g D,L-lactide, 10gε-caprolactone and 0.126g stannous octoate (0.3% of raw material mass). Evacuate, balance with argon, repeat three times. Vacuumize to 20Pa, seal the vacuum reaction bottle, heat the oil bath to 130°C, and react for 48 hours to form a multi-terminated hydroxyl prepolymer.

[0069] (2) Synthesis of double-terminated isocyanate-based prepolymers

[0070] With the double-terminated hydroxyl prepolymer prepared in step 1, connect mechanical stirring, argon protection, heat up to 75 ° C, add chain extender HDI-BDO-HDI dimethyl sulfoxide solution (mass concentration 25%, chain extender According to 1.25 times the molar amount of -NCO / -OH added). Continue the constant temperature reaction at this temperature ...

Embodiment 3

[0076] (1) Synthesis of double-terminated hydroxyl prepolymer

[0077] Put 12g of PEG800 (0.015mol) in a vacuum reaction bottle, stir with a magnet, remove water under vacuum (20Pa) at 100°C for 3h, cool to room temperature, and equilibrate with argon. Add 18g of L-lactide and 0.045g of dibutyltin diacetate (0.15% of raw material mass). Evacuate, balance with argon, repeat three times. Vacuumize to 20Pa, seal the vacuum reaction bottle, heat the oil bath to 140°C, and react for 24 hours to form a multi-terminated hydroxyl prepolymer.

[0078] (2) Synthesis of double-terminated isocyanate-based prepolymers

[0079] With the double-terminated hydroxyl prepolymer prepared in step 1, connect mechanical stirring, argon protection, heat up to 85 ° C, add chain extender HDI-BDO-HDI dimethyl sulfoxide solution (mass concentration 25%, chain extender According to 1.2 times the molar amount of -NCO / -OH added). Continue the constant temperature reaction at this temperature for 2.5 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com