Water-based uv curing ink and preparation method thereof

A water-based ink technology, applied in inks, household utensils, applications, etc., can solve the problem of water-based UV curable ink gloss, hardness, adhesion, aging resistance, wear resistance gap, poor water resistance of water-based UV curable ink, water-based UV Solve problems such as poor stability of cured ink, achieve good aging resistance and solvent resistance, fast curing speed, and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

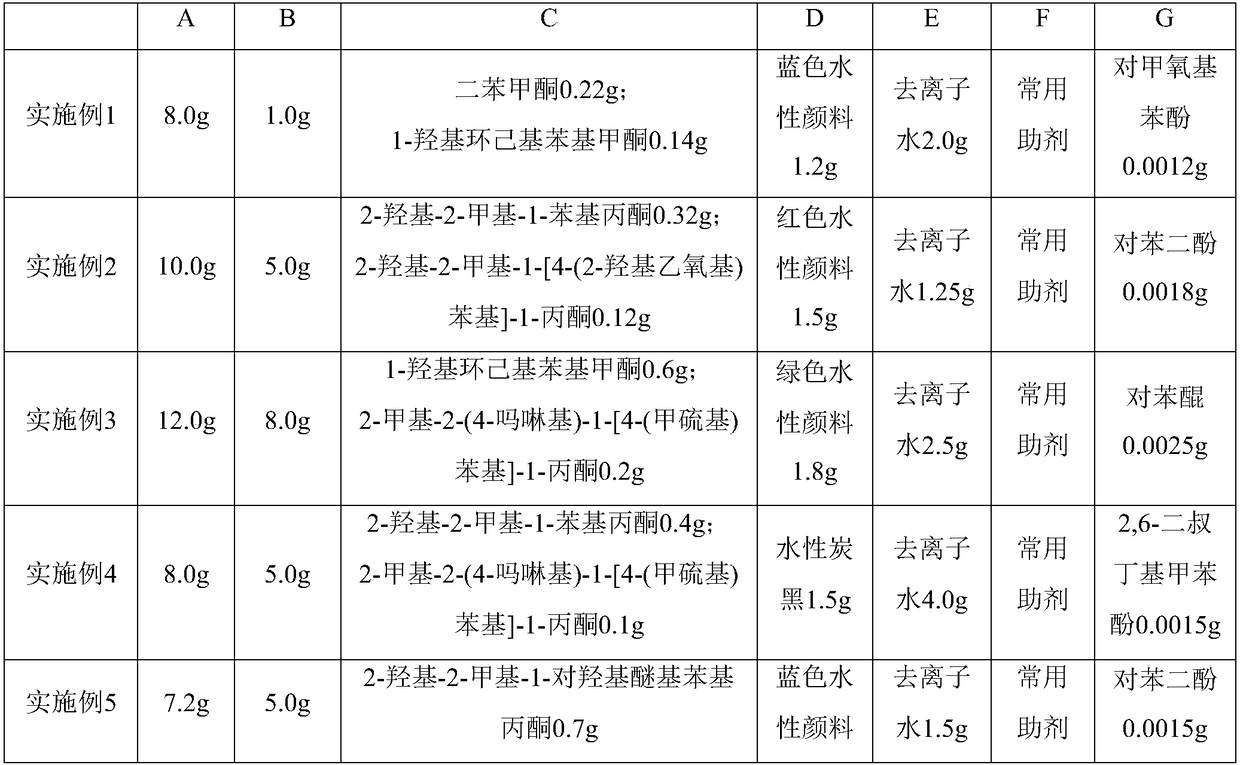

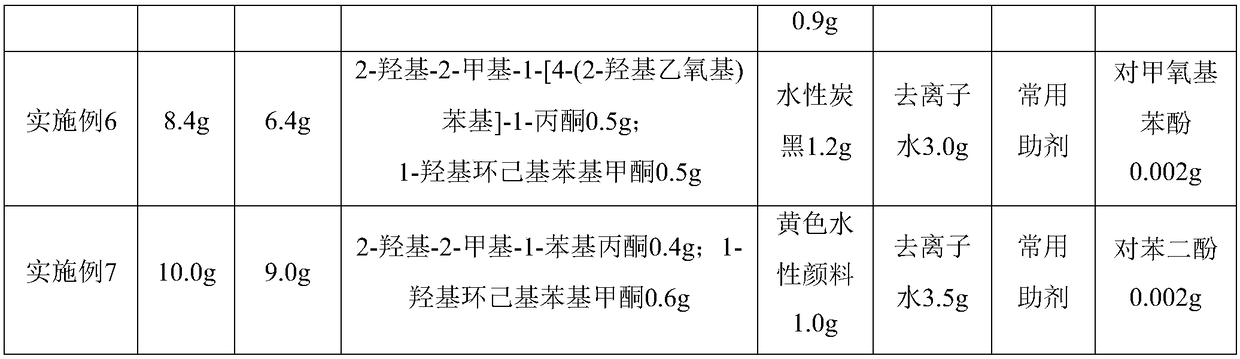

[0059] Table 1 shows the compositions of the aqueous UV-curable inks of Examples 1-7. Wherein, A is a water-based modified polylactic acid acrylate prepolymer; B is a polyvinyl alcohol aqueous solution of soil enzymes with porous hydroxyapatite as a carrier; C is a photoinitiator; D is a colorant; E is a solvent; F is an auxiliary agent; G is a stabilizer.

[0060] The water-based UV curable ink of table 1 embodiment 1-7

[0061]

[0062]

Embodiment 1

[0063] Embodiment 1 preparation method

[0064] (1) Pre-preparation of water-based modified polylactic acid acrylate prepolymer:

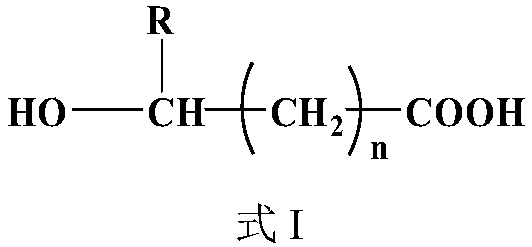

[0065] Add 8.0g of lactic acid, 1.0g of pentaerythritol, and 0.01g of stannous octoate into the reaction kettle, stir at 200r / min, heat to 120°C, distill off water, gradually increase the temperature and reduce pressure to 160°C, 3.0kPa, and accelerate dehydration. After removing the distilled water, continue to reduce the pressure to 2.0kPa, keep 170°C for 2h constant temperature reaction, and cool down to 50-60°C after the reaction; then, add 1.6g of hydroxycarboxylic acid of formula I and 3.0g of polystyrene with a molecular weight of 200 Ethylene glycol, wherein the R group is a methylene carboxyl group, n=4, set the temperature at 85°C for 2 hours; then add 1.5g of hydroxyethyl methacrylate to continue the reaction; after the reaction, add 0.001g of p-formaldehyde Oxyphenol, continue to react at 80°C for 2h, the viscosity of the solution ca...

Embodiment 2

[0073] Embodiment 2 preparation method

[0074] (1) Pre-preparation of water-based modified polylactic acid acrylate prepolymer:

[0075] Add 15.0g of lactic acid, 2.5g of pentaerythritol, and 0.015g of stannous octoate into the reaction kettle, stir at 200r / min, heat to 120°C, distill off water, gradually increase the temperature and reduce pressure to 160°C, 3.0kPa, and accelerate dehydration. After removing the distilled water, continue to reduce the pressure to 2.0kPa, keep 170°C for 2h constant temperature reaction, and cool down to 50-60°C after the reaction; then, add 3.0g of hydroxycarboxylic acid of formula I and 9.0g of poly Ethylene glycol, where the R group is a C=C double bond, n=5, set the temperature at 85°C for 2 hours; add 3.4g of hydroxyethyl methacrylate to continue the reaction; add 0.0018g of terephthalate after the reaction Phenol, continue to react at 80°C for 2h, the viscosity of the solution can be adjusted by adding 5.12g of ethanol; cool down to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com