Method for preparing t-carrageenase

A technology of carrageenase and seeds, applied in the field of biological enzymes, can solve problems such as less research on ι-carrageenase, and achieve the effect of good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] 2 Preparation of iota-carrageenase

[0030] (1) Activation of the strain: the carrageenase-producing strain Pseudoalteromonas carrageenovora ASY5 was inoculated in the seed medium, and activated at 23°C for 24 h.

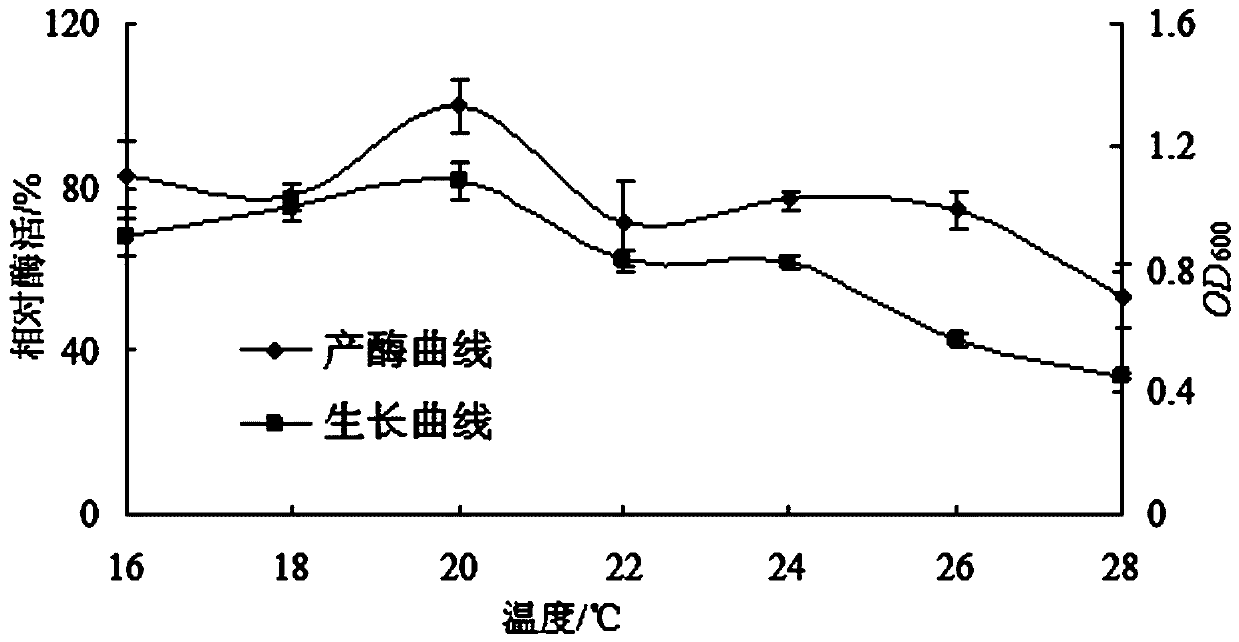

[0031] (2) Fermentation culture: The strains were activated and cultured, then transferred to the fermentation medium, and fermented at 20°C for 40 h.

[0032] (3) Centrifuge the above fermentation broth at 4°C and 10,000 r / min for 20 min, collect the supernatant, and obtain the crude iota-carrageenase enzyme liquid.

[0033] 3. Single factor optimization of ι-carrageenase fermentation process

[0034] The medium composition and culture conditions of the carrageenase-producing strains were optimized by single factor method, and the effects of different factors on the cell density and enzyme production of the strain ASY5 were analyzed. On the basis of shake flask fermentation, the culture time, culture The effects of temperature, inoculum size, liquid volume...

Embodiment 1

[0040] Single factor optimization of ι-carrageenase fermentation process

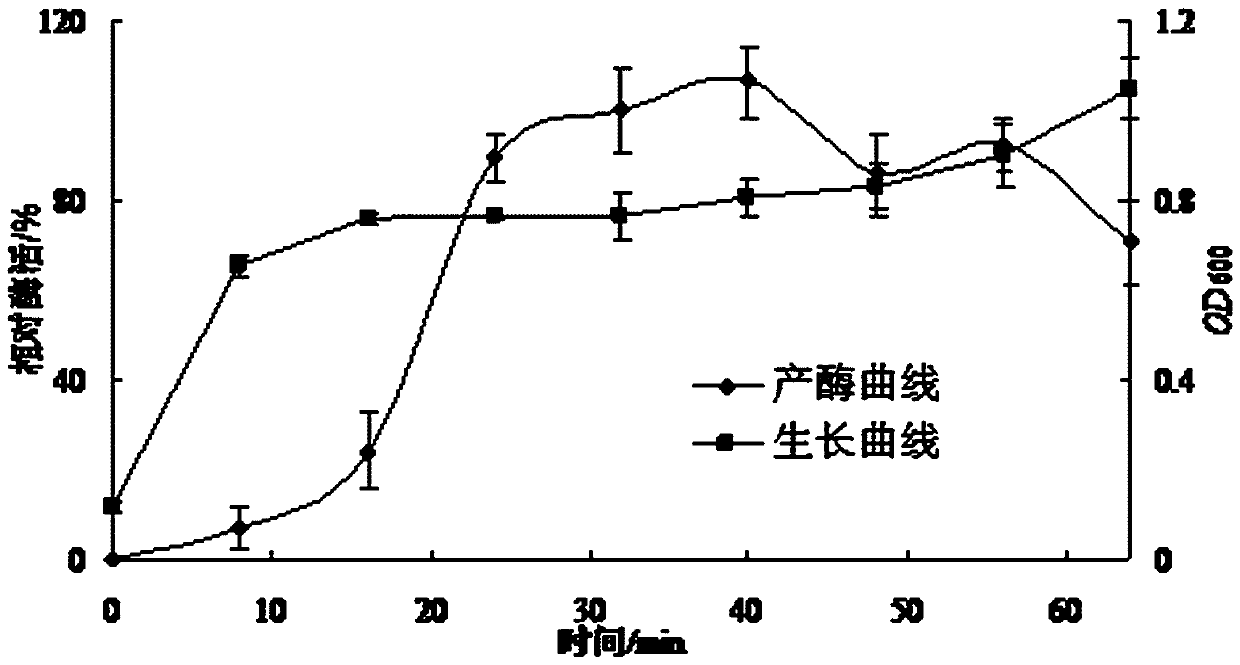

[0041] (1) Effect of culture time on strain growth and enzyme production

[0042] The activated carrageenase-producing strain Pseudoalteromonas carrageenonovora ASY5 was inoculated into the fermentation medium, and cultured at 18°C for 0 h, 8 h, 16 h, 24 h, 32 h, 40 h, 48 h, 56 h, After 64 hours, the cell density was measured respectively, the enzyme solution was collected by refrigerated centrifugation, and the enzyme activity was measured by DNS method to determine the optimal culture time of the medium.

[0043] Depend on figure 2 It can be seen that with the increase of culture time, the enzyme activity showed an upward trend. Between 32 h and 40 h, the enzyme activity of ι-carrageenan tended to be stable, reached the highest value at 40 h, and the enzyme activity began to decline after 40 h. Therefore, it was determined that the optimal culture time for the fermentation and enzyme production o...

Embodiment 2

[0066] The ι-carrageenase fermentation optimization process is contrasted with the initial fermentation process, and according to the optimization parameter of embodiment 1, carries out following experiment:

[0067] 1. Preparation of optimized culture medium

[0068] Artificial seawater: including sodium chloride, potassium chloride, calcium chloride dihydrate, magnesium chloride hexahydrate, sodium bicarbonate, magnesium sulfate heptahydrate, the mass fractions (g / 100 mL) are 2.8, 0.08, 0.16, 0.48, 0.01, 0.35.

[0069] Seed medium: 10 g of beef extract, 10 g of tryptone, add 250 mL of distilled water, adjust the pH to 7.8, bathe in water for 10 min, adjust the pH to 7.3, then add 750 mL of artificial sea water, mix well, sterilize at 121 °C for 15 min, Store at 4°C after cooling.

[0070] Fermentation medium: sodium chloride 15 g, yeast powder 15 g, calcium chloride dihydrate 0.2 g, disodium hydrogen phosphate dodecahydrate 3.82 g, sodium dihydrogen phosphate dihydrate 1.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com