Dyeing method for modified polyimide fabrics

A polyimide and dyeing method technology, applied in the field of fabric dyeing, can solve the problems of polyimide dyeing difficulties, limited application, increased dyeing difficulty, etc., and achieve good dyeing effect, good color fastness and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

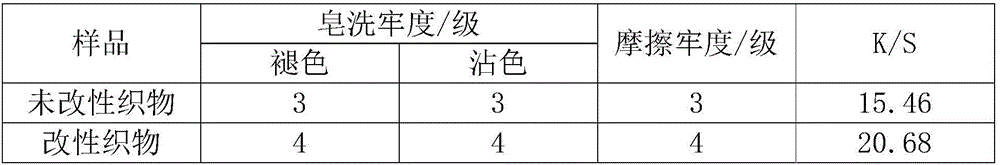

Embodiment 1

[0038] A kind of dyeing method of modified polyimide fabric, comprises the following steps:

[0039] Clean the polyimide fabric with 1g / L sodium carbonate solution in ultrasonic wave for 5min at 40°C; then clean the polyimide fabric with absolute ethanol solution in ultrasonic wave for 2min at 20°C; Then the polyimide fabric was cleaned with deionized water for 1min; wherein, the power used for ultrasonic cleaning was 100kHz;

[0040] Put the cleaned polyimide fabric into an oven and dry it at 30°C;

[0041] The polyimide fabric is pretreated with low-temperature plasma, the treatment power is 100W, the treatment time is 1min, and the treatment atmosphere is oxygen;

[0042] The polyimide fabric after plasma treatment was quickly put into the acrylic acid solution, the bath ratio was 1:40, the temperature was 30°C, and it was stirred continuously. The acrylic acid solution was made of acrylic acid and deionized water with a volume ratio of :1 mixed;

[0043] After the graft...

Embodiment 2

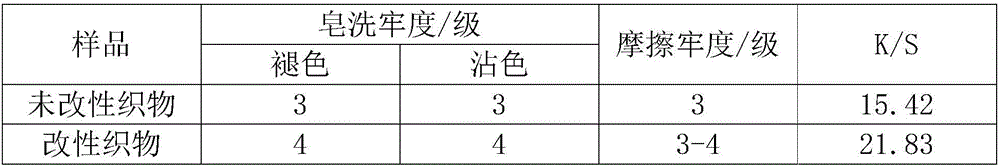

[0051] A kind of dyeing method of modified polyimide fabric, comprises the following steps:

[0052] Clean the polyimide fabric with 5g / L sodium carbonate solution in ultrasonic for 10min at 100°C; then clean the polyimide fabric with absolute ethanol and acetone solution in ultrasonic for 10min at 60°C ℃; then the polyimide fabric was cleaned with deionized water for 5 minutes; wherein, the power used for ultrasonic cleaning was 70kHz;

[0053] Put the cleaned polyimide fabric into an oven and dry it at 100°C;

[0054] The polyimide fabric is pretreated with low-temperature plasma, the treatment power is 500W, the treatment time is 30min, and the treatment atmosphere is argon;

[0055] The polyimide fabric after plasma treatment was quickly put into the acrylic acid solution, the bath ratio was 1:150, the temperature was 80°C, and the acrylic acid solution was made of acrylic acid and deionized water with a volume ratio of 1 :10 mixed;

[0056] After the grafting reaction ...

Embodiment 3

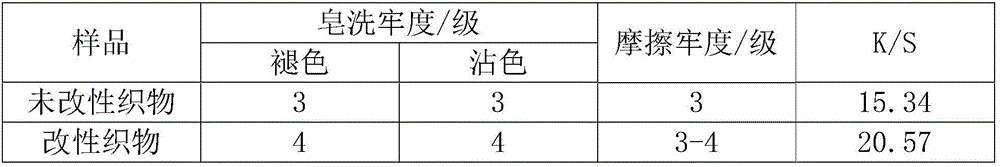

[0064] A kind of dyeing method of modified polyimide fabric, comprises the following steps:

[0065] Clean the polyimide fabric with a 10g / L sodium carbonate solution in an ultrasonic wave for 8 minutes at a temperature of 80°C; then clean the polyimide fabric with an absolute ethanol solution in an ultrasonic wave for 5 minutes at a temperature of 45°C; Then the polyimide fabric was cleaned with deionized water for 3 minutes; wherein, the power used for ultrasonic cleaning was 40kHz;

[0066] Put the cleaned polyimide fabric into an oven and dry it at 80°C;

[0067] The polyimide fabric is pretreated with low-temperature plasma, the treatment power is 300W, the treatment time is 10min, and the treatment atmosphere is nitrogen;

[0068] The polyimide fabric after plasma treatment was put into the acrylic acid solution quickly, the bath ratio was 1:100, the temperature was 45°C, and it was stirred continuously. :5 mixed;

[0069] After the grafting reaction was completed, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com