Modified carbon material and preparation method thereof, cathode lead paste, polar plate and lead carbon battery

A technology of lead-carbon battery and modified carbon, which is applied in the fields of modified carbon materials for lead-carbon batteries, pole plates and lead-carbon batteries, and negative electrode paste. It can solve the problem of adding capacitor materials to increase battery self-discharge and damage lead-acid batteries Charge and discharge capacity, increase in battery water consumption and other issues, to achieve the effect of enhancing charge acceptance, improving high rate charge and discharge capacity, and inhibiting hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

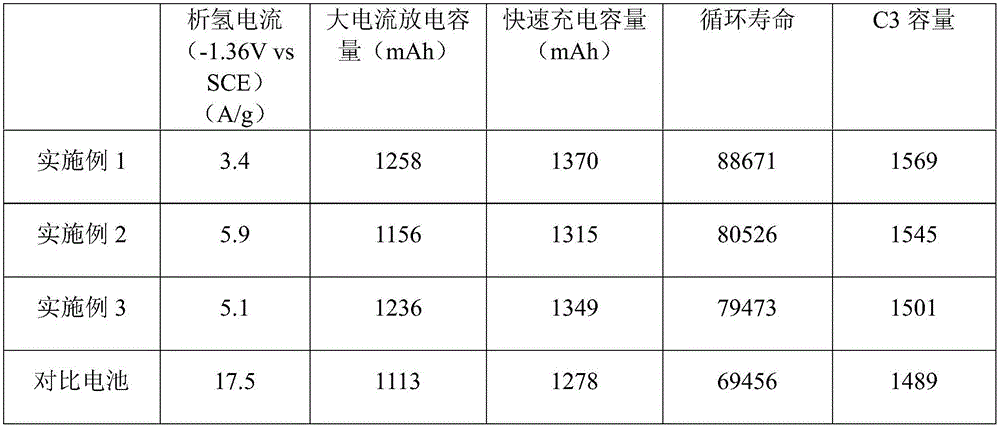

Examples

preparation example Construction

[0037] In a preferred embodiment of the present invention, the preparation method of modified carbon material for lead-carbon battery comprises the following steps:

[0038] 1) The biomass material is placed in a pulverizer to pulverize, with an average particle size of 0.1-0.5cm;

[0039] 2) Treat the pulverized biomass material with an acid and / or alkali solution for 12 to 36 hours to remove impurities in the biomass material and filter to obtain a precursor;

[0040] The acid and alkali solutions include: sodium hydroxide, potassium hydroxide, sulfuric acid, nitric acid, and the concentration of the acid and alkali solutions is 0.1-2mol / L;

[0041] 3) Place the precursor in an aqueous solution containing a high hydrogen evolution overpotential metal salt, disperse it by ultrasonic vibration for 0.5-5 hours, stir for 0.5-5 hours, filter and wash with deionized water until the pH of the filtrate is about 7, and obtain a modified precursor;

[0042] The high hydrogen evolutio...

Embodiment 1

[0050] A preparation method for a modified carbon material for a lead-carbon battery, comprising the following steps:

[0051] 1) The rice husk is placed in a pulverizer to pulverize, with an average particle size of 0.1-0.5cm;

[0052] 2) Treat the pulverized rice husk with a 1mol / L sodium hydroxide solution for 24 hours to remove impurities in the rice husk, and filter to obtain the precursor;

[0053] 3) Place the precursor in an aqueous solution of lead nitrate containing 1mol / L, the mass ratio of lead nitrate to precursor is 0.5:1, disperse by ultrasonic vibration for 2 hours, stir for 2 hours, filter and wash with deionized water until the pH of the filtrate is about 7 , to obtain the modified precursor;

[0054] The ultrasonic vibration frequency is 30KHz, and the stirring rate is 1000r / min;

[0055] 4) The modified precursor is placed in a heating device, and the modified precursor is preheated, dried, carbonized and activated to obtain a modified carbon material; th...

Embodiment 2

[0060] A preparation method for a modified carbon material for a lead-carbon battery, comprising the following steps:

[0061] 1) Put lignin, corn cob and coconut shell in a pulverizer to pulverize, with an average particle size of 0.1-0.5cm;

[0062] 2) Treat the pulverized lignin, corn cob and coconut shell with 2mol / L potassium hydroxide solution for 12 hours, remove the impurities in lignin, corn cob and coconut shell, and filter to obtain the precursor;

[0063] 3) Place the precursor in an aqueous solution of lead chloride and zinc citrate with a total concentration of 5mol / L, the mass ratio of lead chloride and zinc citrate to the precursor is 2:1, disperse by ultrasonic vibration for 0.5h, and stir for 0.5 h, after filtering, wash with deionized water until the filtrate pH=7 or so to obtain a modified precursor;

[0064] The ultrasonic vibration frequency is 50KHz, and the stirring rate is 1800r / min;

[0065] 4) The modified precursor is placed in a heating device, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com