Wood-plastic wall panel and production method thereof

A wall panel and wood-plastic technology, applied in the field of building boards, can solve the problems of poor water resistance, easy aging, easy deformation, etc., and achieve the effect of preventing mold or insects, not easy to age, and buffering external impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

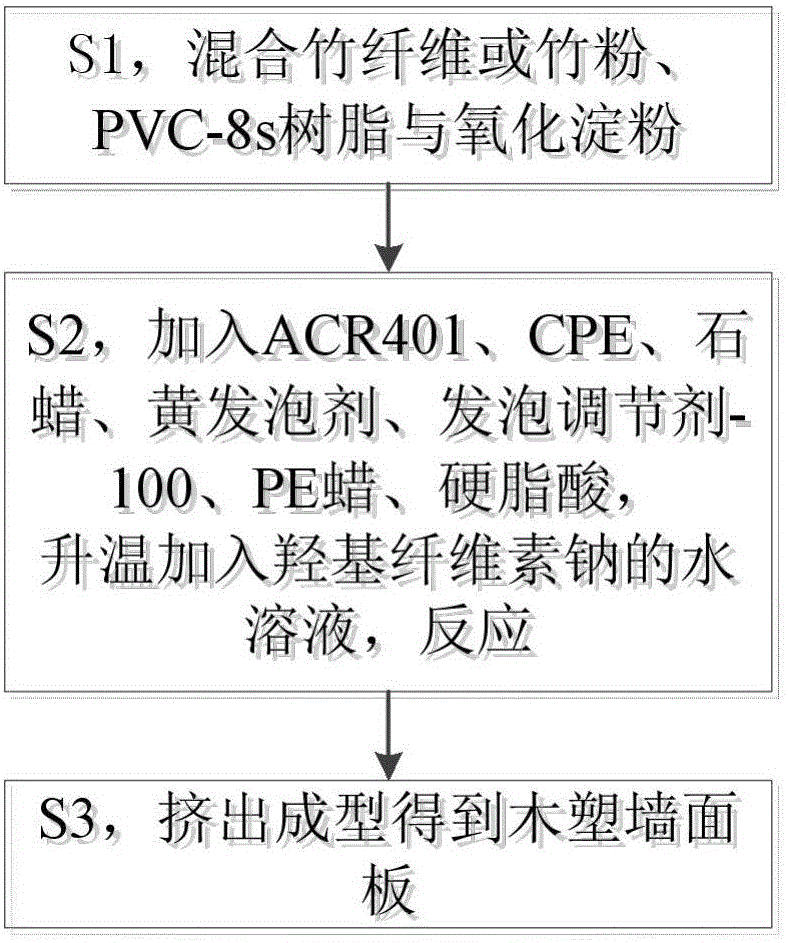

[0020] The preparation of the wood-plastic wall panel of this embodiment comprises the following steps,

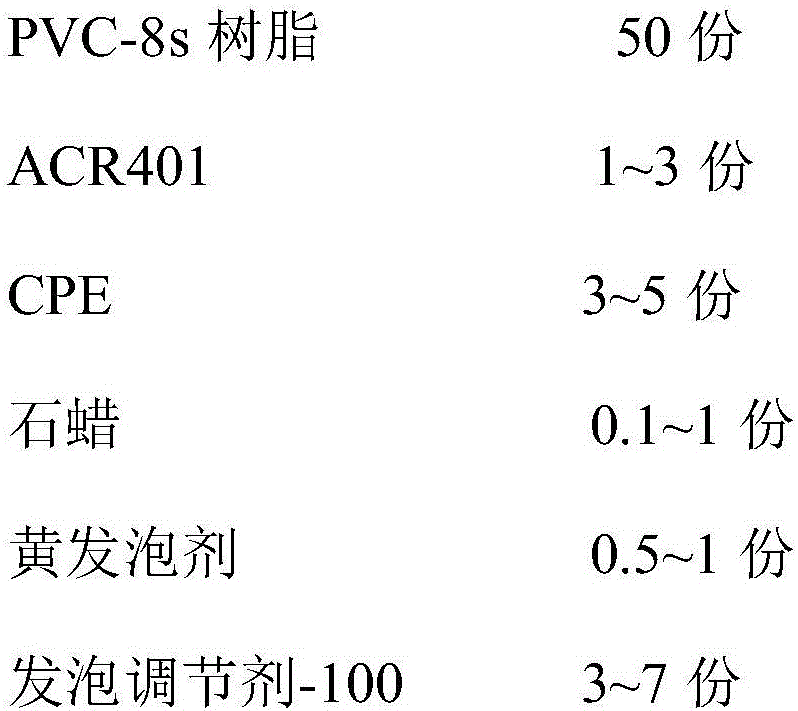

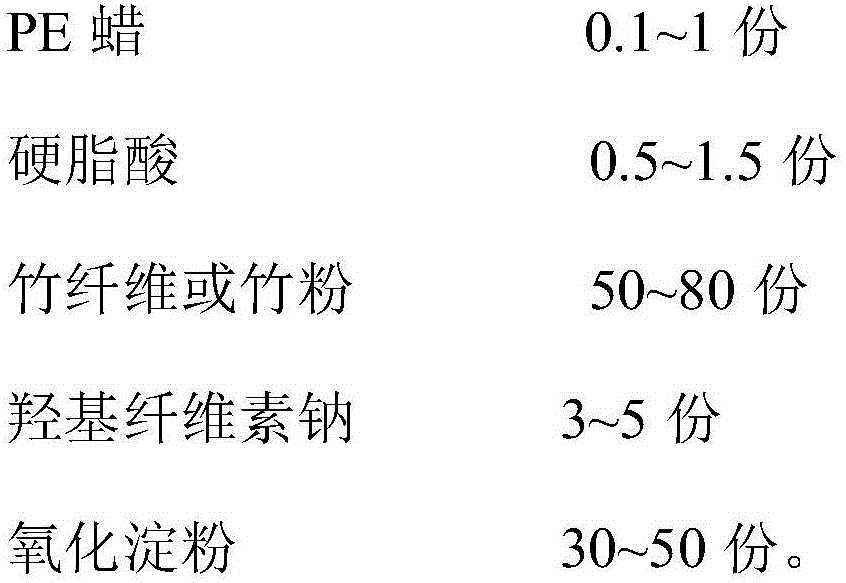

[0021] S1, crushing 50 parts of bamboo fiber to more than 40 meshes, and then mixing evenly with 50 parts of PVC-8s resin and 30 parts of oxidized starch;

[0022] S2, add 1 part of ACR401, 3 parts of CPE, 0.1 part of paraffin, 0.5 part of yellow foaming agent, 3 parts of foam regulator-100, 0.1 part of PE wax, 0.5 part of stearic acid and heat up to 60 ° C, add 3 parts of hydroxyl Aqueous solution of sodium cellulose, reacted for 1 hour, dried;

[0023] S3, extruding to obtain a wood-plastic wall panel.

[0024] After testing, the wood-plastic wall panel prepared in this embodiment,

[0025] Pull strength: ≥8.0%;

[0026] Water absorption (one standard atmospheric pressure): ≤3%;

[0027] Shore hardness (a): ≥47;

[0028] Apparent density: ≥0.45g / ml;

[0029] Impact strength: ≥14.4KJ / m 2 .

Embodiment 2

[0031] The preparation of the wood-plastic wall panel of this embodiment comprises the following steps,

[0032] S1, mix and pulverize 65 parts of bamboo fiber and bamboo powder to more than 40 meshes, then mix evenly with 50 parts of PVC-8s resin and 30-50 parts of oxidized starch;

[0033] S2, add 1-3 parts of ACR401, 3-5 parts of CPE, 0.1-1 part of paraffin wax, 0.8 parts of yellow foaming agent, 5 parts of foaming regulator-100, 0.5 parts of PE wax, 1 part of stearic acid and heat up to 75 ℃, add 4 parts of aqueous solution of sodium hydroxycellulose, react for 1.5 hours, and dry;

[0034] S3, extruding to obtain a wood-plastic wall panel.

[0035] After testing, the wood-plastic wall panel prepared in this embodiment,

[0036] Pull strength: ≥8.0%;

[0037] Water absorption (one standard atmospheric pressure): ≤3%;

[0038] Shore hardness (a): ≥47;

[0039] Apparent density: ≥0.45g / ml;

[0040] Impact strength: ≥14.4KJ / m 2 .

Embodiment 3

[0042] The preparation of the wood-plastic wall panel of this embodiment comprises the following steps,

[0043] S1, pulverize 80 parts of bamboo powder to more than 40 meshes, then mix evenly with 50 parts of PVC-8s resin and 50 parts of oxidized starch;

[0044] S2, add 3 parts of ACR401, 5 parts of CPE, 1 part of paraffin wax, 1 part of yellow foaming agent, 7 parts of foam regulator-100, 1 part of PE wax, 1.5 parts of stearic acid and raise the temperature to 85 ° C, add 5 parts of hydroxyl Aqueous solution of sodium cellulose, reacted for 2 hours, and dried;

[0045] S3, extruding to obtain a wood-plastic wall panel.

[0046] After testing, the wood-plastic wall panel prepared in this embodiment,

[0047] Pull strength: ≥8.0%;

[0048] Water absorption (one standard atmospheric pressure): ≤3%;

[0049] Shore hardness (a): ≥47;

[0050] Apparent density: ≥0.45g / ml;

[0051] Impact strength: ≥14.4KJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com