Dye wastewater deep purification and reuse system as well as method thereof

A technology for dye wastewater and deep purification, applied in the field of water treatment, can solve the problems of fouling, membrane fouling and clogging, and high investment and operating cost of membrane separation technology, so as to slow down membrane flux decline, prolong membrane life, and reduce organic pollution. and the effects of microbial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

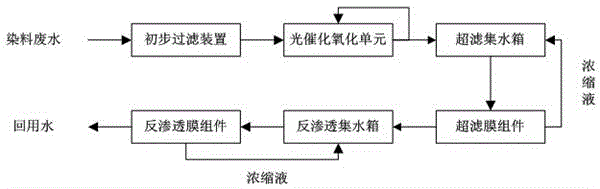

[0034] Example 1: Printing and dyeing wastewater enters the deep purification and reuse system of dye wastewater after conventional physical and chemical + biochemical treatment. Processed through the following steps:

[0035] 1) Preliminary filtration: Multi-layer screen is used to filter, large particle impurities are retained, and other parameters do not change much;

[0036] 2) Photocatalytic oxidation unit: The wastewater after the above treatment enters the photocatalytic oxidation reactor, and a three-dimensional foamed nickel mesh loaded with titanium dioxide is added to the reactor, with a total mass of 65.76 g; the light source is an ultraviolet lamp, and the reaction is carried out at 32°C for 120 minutes After that, the COD of the produced water decreased by 19%, the chroma decreased by 75%, and other parameters did not change much;

[0037] 3) Ultrafiltration membrane separation unit: The treated wastewater enters the ultrafiltration membrane separation unit. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com