Preparation method for olaparib

A technology of piperazine and carbonyl, which is applied in the field of preparation of olaparib, can solve the problems of high activity of cyclopropylformyl chloride, low yield of olaparib, cumbersome purification steps, etc., and achieve good industrial application prospects, method Convenience and high chromatographic purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

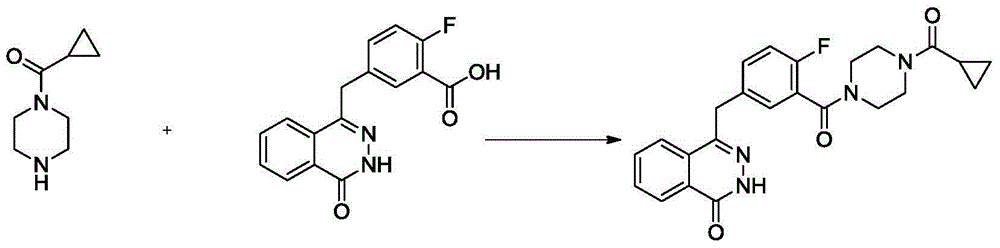

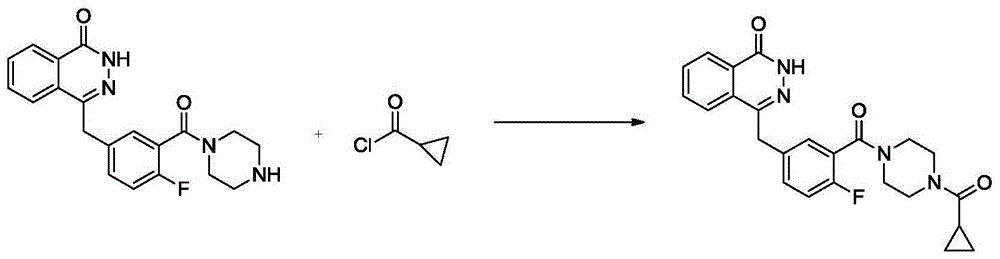

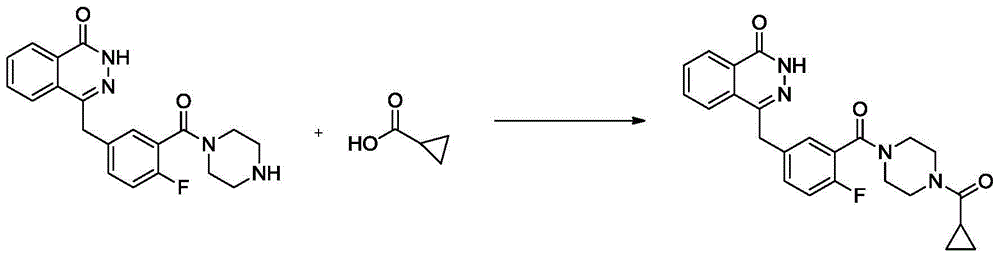

Method used

Image

Examples

Embodiment 1

[0036]

[0037] At 10°C, add 2000ml of N,N-dimethylacetamide to the reaction kettle, and add 4-(4-fluoro-3-(piperazine-1-carbonyl)benzyl)phthalein-1( 2-Hydro)-ketone (40g, 0.109mol), HBTU (48g, 0.127mol), cyclopropanecarboxylic acid (12g, 0.139mol), and finally N,N-diisopropylethylamine (0.218mol, 28.17g , 38ml), after reacting at 10°C for 8 hours, add 800ml of water, slowly precipitate the solid, suction filter, wash, and dry to obtain 42g of white solid, namely olaparib; HPLC purity 99.83%, yield 88.6%.

[0038] NMR data of olaparib:

[0039] 1 H NMR(400Hz,DMSO)δ12.598(s,1H),8.26(dd J=10.0Hz,1.4Hz,1H),7.96(dJ=10.0Hz,1H),7.90(dJ=8.2Hz,1H) ,7.80-7.86(m,1H),7.42-7.46(m,1H),7.38(d J=7.7Hz,1H),7.23(d J=12.2Hz,1H),4.33(s,2H),3.41- 3.74 (m, 6H), 3.19 (s, 2H), 1.94 (d J = 22.7Hz, 1H), 0.70-0.75 (m, 4H).

[0040] 13 C NMR (100Hz, DMSO) δ171.2, 164.0, 159.3, 158.0, 154.7, 144.7, 134.8, 134.7, 133.4, 131.7, 131.6, 131.4, 129.0, 128.93, 128.88, 127.9, 126.0, 1047.3, 126.3 ,46.4...

Embodiment 2

[0042]

[0043] At 50°C, add 2000ml of N,N-dimethylacetamide into the reaction kettle, and add 4-(4-fluoro-3-(piperazine-1-carbonyl)benzyl)phthalein-1( 2-Hydro)-ketone (40g, 0.109mol), HBTU (48g, 0.127mol), cyclopropanecarboxylic acid (12g, 0.139mol), and finally N,N-diisopropylethylamine (0.218mol, 28.17g , 38ml), reacted at 50°C for 4 hours, cooled to room temperature, added 800ml of water, slowly precipitated solid, suction filtered, washed, and dried to obtain 39g of white solid, namely olaparib; HPLC purity 99.81%, yield 82.3 %.

Embodiment 3

[0045]

[0046] At 10°C, add 2000ml of N,N-dimethylformamide into the reaction kettle, and add 4-(4-fluoro-3-(piperazine-1-carbonyl)benzyl)naphthyridine-1( 2-hydrogen)-ketone (40g, 0.109mol), HOBT (17.67g, 0.131mol), cyclopropanecarboxylic acid (12g, 0.139mol) g, finally added triethylamine (19.66g, 0.194mol, 27mL), 20 Stir at ℃ for about 7 hours. After the reaction, add 800ml of water, stir, and slowly precipitate solids, suction filter, wash, and dry to obtain 43.2 g of white solids, namely olaparib; HPLC purity 99.92%, yield 91.2% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com