Preparation method of a composition-controllable tin-based oxide and its photocatalytic application

An oxide and photocatalysis technology, which is applied in tin oxide, light water/sewage treatment, energy wastewater treatment, etc., can solve the problems of small product composition modulation space, high preparation cost, and high equipment requirements, and achieve high-efficiency visible light photocatalysis Degradation and decolorization activity, improved degradation rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

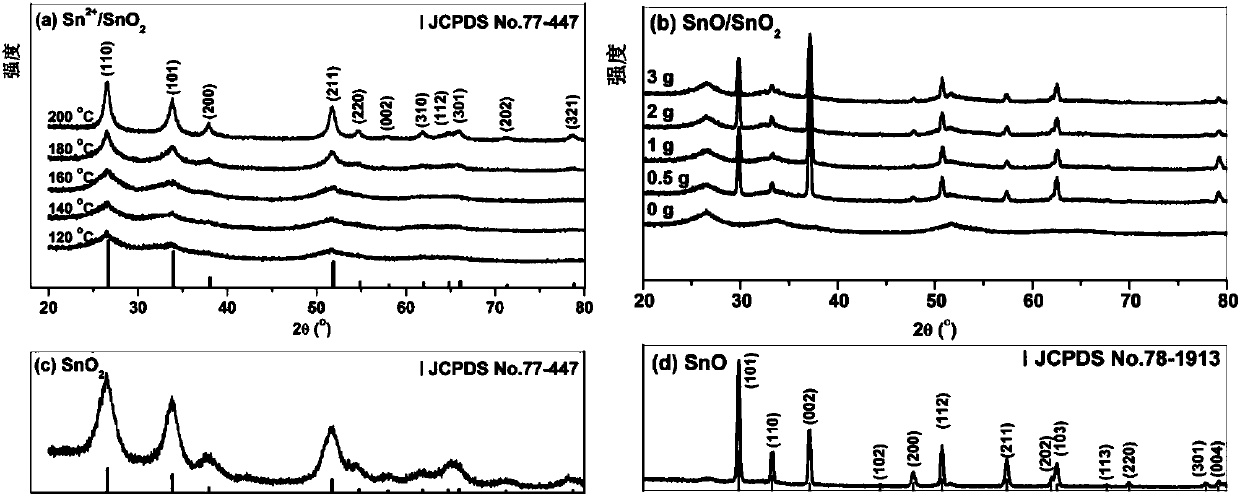

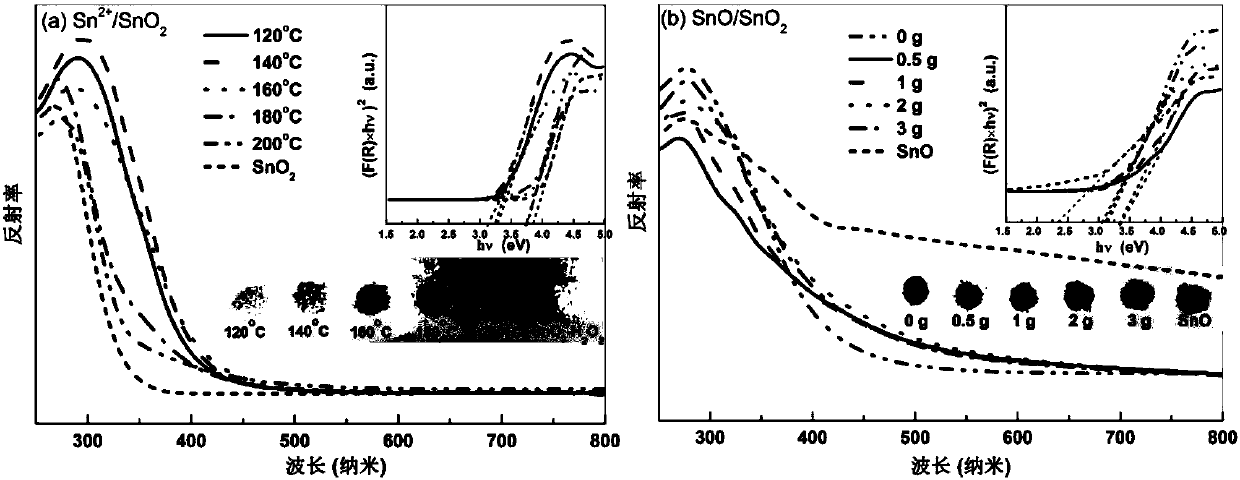

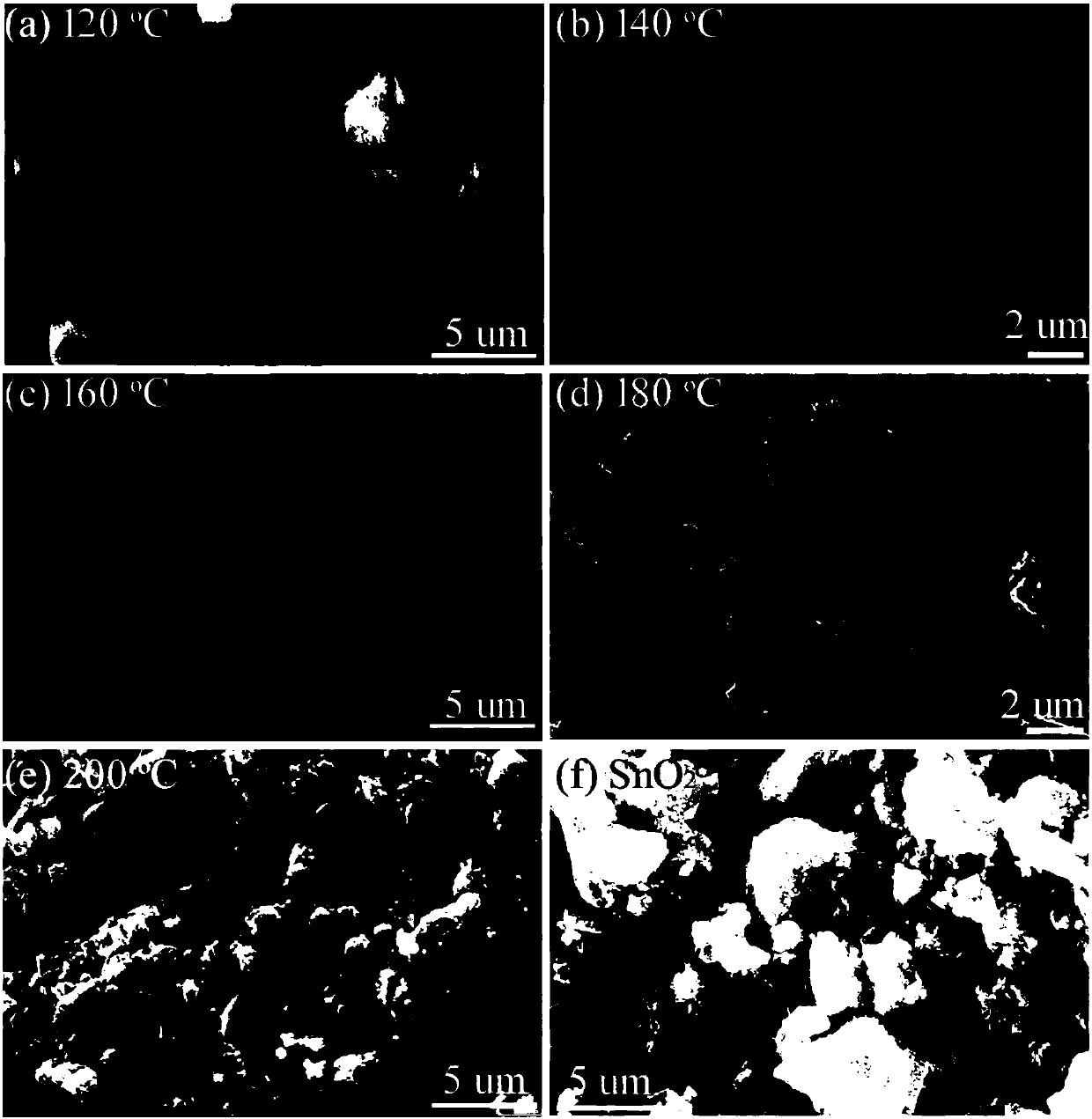

[0047] This embodiment prepares Sn according to the following steps 2+ / SnO 2 :

[0048] a. Take 1g SnCl 2 2H 2 O was added to a polytetrafluoroethylene container, then 80mL of water was added, and stirred until dissolved to obtain a hydrothermal solution; five samples were made in parallel;

[0049] b. Seal five polytetrafluoroethylene containers filled with hydrothermal solutions and put them into stainless steel hydrothermal kettles, and then place them in blast ovens at 120°C, 140°C, 160°C, 180°C, and 200°C respectively. After heat treatment for 24 hours, the product solution was obtained after natural cooling to room temperature;

[0050] c. The product solution is subjected to centrifugation, washing and vacuum drying at 80°C to obtain Sn 2+ / SnO 2 sample. The obtained sample was light yellow solid, and the color of the sample gradually deepened as the temperature increased.

Embodiment 2

[0052] This embodiment prepares SnO / SnO according to the following steps 2 :

[0053] a. Weigh 1g of SnCl with an electronic balance 2 2H 2 O was added to the polytetrafluoroethylene container, and 0.5g, 1g, 2g, 3g of urea were added respectively, then 80mL of water was added, stirred until dissolved, and a hydrothermal solution was obtained;

[0054] b. Seal the polytetrafluoroethylene container containing the hydrothermal solution and put it into a stainless steel hydrothermal kettle, then place it in a blast oven at 160°C for hydrothermal treatment for 24 hours, and naturally cool to room temperature to obtain the product solution;

[0055] c. The product solution is subjected to centrifugal separation, washing and vacuum drying at 80°C to obtain SnO / SnO 2 . The obtained sample is a gray-black solid, and the color of the sample gradually deepens as the amount of urea increases.

Embodiment 3

[0057] This embodiment prepares SnO according to the following steps 2 :

[0058] a. Take 1g SnCl 2 2H 2 0 and 3g of urea were added to the polytetrafluoroethylene container, then 80mL of water and 1mL of mass concentration were added to be 30% hydrogen peroxide, and the mixture was evenly stirred to obtain a hydrothermal solution;

[0059] b. Seal the polytetrafluoroethylene container containing the hydrothermal solution and put it into a stainless steel hydrothermal kettle, then place it in a blast oven at 160°C for hydrothermal treatment for 24 hours, and naturally cool to room temperature to obtain the product solution;

[0060] c. The product solution is subjected to centrifugal separation, washing and vacuum drying at 80°C to obtain SnO 2 . The obtained sample was a white powdery solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com