Titanium dioxide/tin sulfide composite material, preparation method and application thereof

A titanium dioxide, composite material technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of narrow light response range and low quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation of titanium dioxide / tin sulfide composite material: dissolve sulfur source (such as thioacetamide or thiourea) and tin source (such as tin tetrachloride) in water (such as distilled water), add titanium dioxide mesoporous material, and disperse evenly , using a hydrothermal method to keep the temperature at 120-250° C. for 1-96 hours to obtain a titanium dioxide / tin sulfide composite material. The hydrothermal method may be to use a high-pressure reactor to keep warm at 120-250° C. for 1-96 hours.

[0032] As a detailed example, titanium dioxide mesoporous spheres are dispersed in an aqueous solution of tin source and sulfur source. Tin tetrachloride and thioacetamide, titanium dioxide mesoporous spheres, the dosages of tin tetrachloride and thioacetamide are 0.5g, 0~0.4376g and 0~0.0188g respectively, and the hydrothermal reaction conditions are 150℃ Keep warm for 24 hours.

[0033] Preparation of mesoporous titanium dioxide / tin sulfide composite material...

Embodiment 1

[0045] Dissolve 5.0g of hexadecylamine in 1000ml of absolute ethanol, add 4.0ml of 0.1M potassium chloride aqueous solution, stir well, slowly add 20ml of titanium isopropoxide at a speed of 10ml / min, let it stand for 8 hours and centrifuge to obtain white Titanium dioxide amorphous powder.

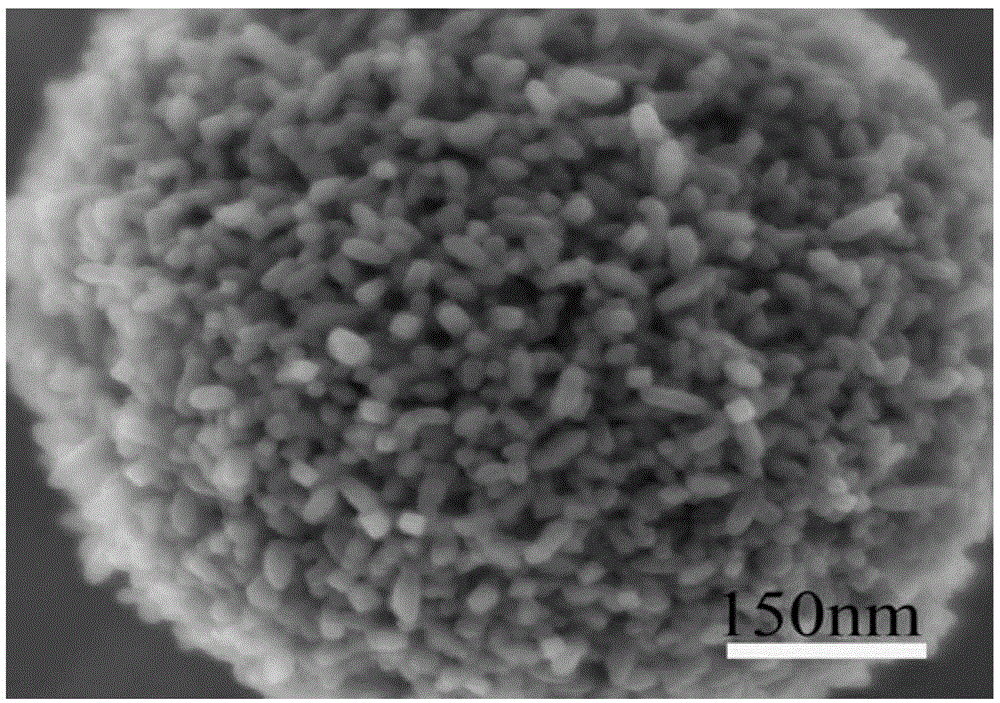

[0046] Take 2.0g of titanium dioxide amorphous powder, disperse it in 20ml of ethanol and 20ml of water, evenly disperse it, transfer it to a 50ml reaction kettle, keep it warm at 150°C for 20h, filter and wash it to obtain titanium dioxide mesoporous spherical powder, see figure 1 , which shows the SEM image of the obtained titanium dioxide mesoporous spherical powder, from which it can be seen that the obtained titanium dioxide mesoporous spherical powder has a mesoporous structure with a size of 500-1000 nm.

[0047] Take 0.5g of pure titanium dioxide particle powder, add 15ml of absolute ethanol, and ball mill for 24 hours to obtain a titanium dioxide / ethanol dispersion, which is scra...

Embodiment 2

[0050] Dissolve 5.0g of hexadecylamine in 1000ml of absolute ethanol, add 4.0ml of 0.1M potassium chloride aqueous solution, stir well, slowly add 20ml of titanium isopropoxide at a speed of 10ml / min, let it stand for 8 hours and centrifuge to obtain white Titanium dioxide amorphous powder.

[0051] Take 2.0g of titanium dioxide amorphous powder, disperse it in 20ml of ethanol and 20ml of water, after the dispersion is uniform, transfer it to a 50ml reaction kettle, keep it warm at 150°C for 20h, filter and wash it, and obtain titanium dioxide mesoporous powder.

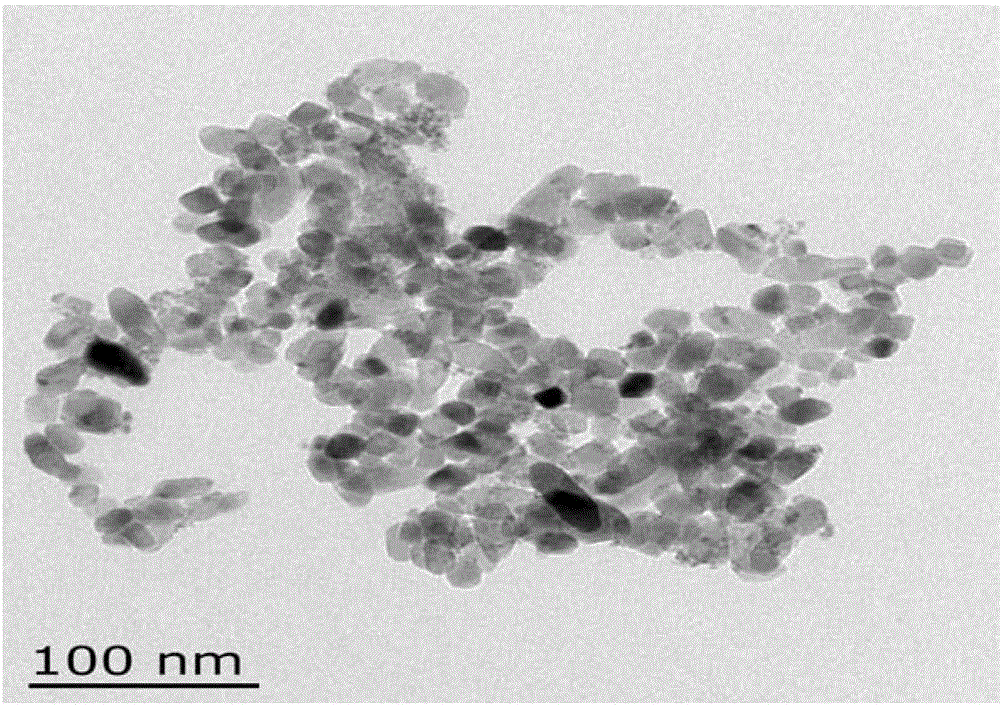

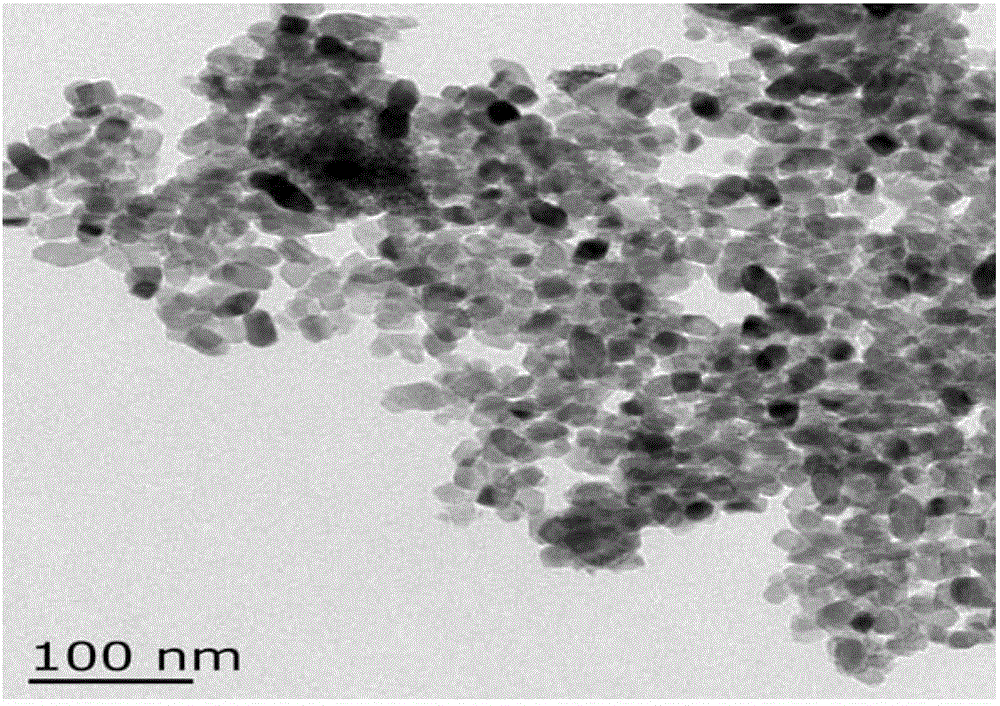

[0052] Take 0.5g titanium dioxide mesoporous powder, 0.1094g tin tetrachloride pentahydrate crystal and 0.0047g thioacetamide, disperse in 30ml distilled water, transfer to 50ml reaction kettle after dispersing evenly, keep it warm at 150℃ for 24h, centrifuge After washing and drying, a titanium dioxide / tin sulfide composite material is obtained. The TEM photo of the composite material in this example is shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com