Ultrafine aluminum alloy powder and production method thereof

A technology of aluminum alloy powder and production method, which is applied in the field of powder metallurgy and can solve problems such as large-scale preparation that has not been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

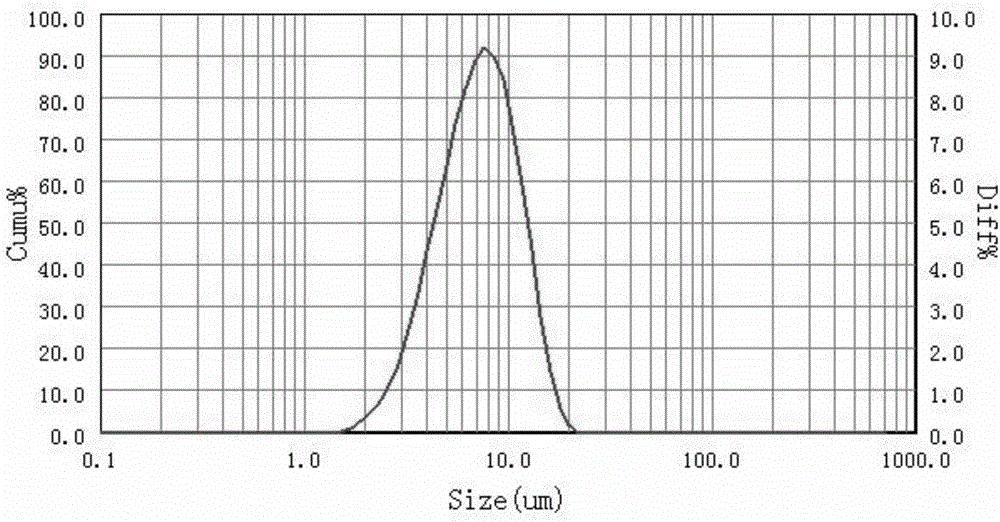

Image

Examples

Embodiment 1

[0039] Example 1: Add 92.05-94.35 kg of metal aluminum ingot with a purity of 99.85% into a non-polluting crucible and heat it to 700°C, then add 3.8-4.9 kg of metal copper with a purity of more than 99%, 0.3-0.9 kg of manganese, and 1.2-4 kg of magnesium. Add 1.8kg, 0.1kg of chromium, and 0.25kg of zinc (the total mass of aluminum and other alloy elements is 100.00kg) into the molten aluminum, heat up to above 950°C, and transfer to the holding furnace for standby. Vacuum the atomization system, and when the pressure in the system is reduced to 40Pa, feed high-purity nitrogen >99.99% to ensure that the oxygen content in the system is below 100ppm. At the same time, use the compressor to pressurize the high-purity nitrogen gas (purity above 99.99%) to 9MPa, heat the high-purity nitrogen gas (purity above 99.99%) to 700°C through the heating tube, and pass the alloy liquid in the insulation bag through the atomizer Into the airtight atomization system that is sprayed into, unde...

Embodiment 2

[0040] Example 2: Add 97.0 to 97.5 kg of aluminum ingot with a purity of 99.85% into a non-polluting crucible and heat it to 700°C, then add 0.6 kg of silicon metal with a purity of more than 99%, 0.7 kg of iron, 0.1 kg of copper, and 0.9 to 0.9 kg of manganese. 1.5kg and 0.1kg of zinc (the total mass of aluminum and other alloy elements is 100.00kg) are added to the molten aluminum, the temperature is raised to above 920°C, and transferred to the holding furnace for standby. Vacuum the atomization system, and when the pressure in the system drops to 40Pa, feed high-purity nitrogen (purity>99.99%) to ensure that the oxygen content in the system is below 100ppm. At the same time, use the compressor to pressurize the high-purity nitrogen gas (purity above 99.99%) to 7MPa, heat the high-purity nitrogen gas (purity above 99.99%) to 600°C through the heating tube, and atomize the aluminum alloy liquid in the insulation bag In the closed atomization system injected by the sprayer, t...

Embodiment 3

[0042] Put 95.9~96.7kg of metal aluminum ingot with a purity of 99.85% into a pollution-free crucible and heat it to 700°C, then add 0.25kg of metal silicon with a purity of more than 99%, 0.4kg of iron, 0.1kg of copper, 0.1kg of manganese, and 2.2~ Add 2.8kg of zinc, 0.1kg of chromium, and 0.15kg of chromium (the total mass of aluminum and other alloying elements is 100.00kg) into molten aluminum, raise the temperature to above 950°C, and transfer to the holding furnace for standby. Vacuum the atomization system, and when the pressure in the system drops below 40Pa, feed high-purity nitrogen (purity>99.99%) to ensure that the oxygen content in the system is below 100ppm. At the same time, use the compressor to pressurize the high-purity nitrogen gas (purity above 99.99%) to 10MPa, heat the high-purity nitrogen gas (purity above 99.99%) to 500°C through the heating tube, and atomize the aluminum alloy liquid in the insulation bag In the closed atomization system injected by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com