Concentration technology for producing lithium salt by sulfuric acid method

A technology of lithium sulfate and sulfuric acid method, which is applied in the direction of lithium sulfate/sulfite, lithium carbonate; Problems such as high cost and difficulty, to achieve the effect of small processing difficulty, low production cost, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of enrichment process for the production of sulfuric acid lithium salt, comprises the following steps:

[0038] 1) Softening pretreatment: use resin to alternately adsorb calcium and magnesium ions in the raw solution to obtain a lithium sulfate leaching solution with a total content of calcium and magnesium ions of 0.6 mg / L.

[0039] 2) Membrane filtration: the lithium sulfate leaching solution obtained in step 1) is utilized to carry out membrane filtration by a microfiltration membrane made of polysulfone, the microfiltration membrane aperture is 5 μm, and the pressure of the lithium sulfate leaching solution through the microfiltration membrane is 0.02MPa to obtain Solid impurity and solid content are 4.8ppm, lithium ion content is the lithium sulfate solution of 20g / L;

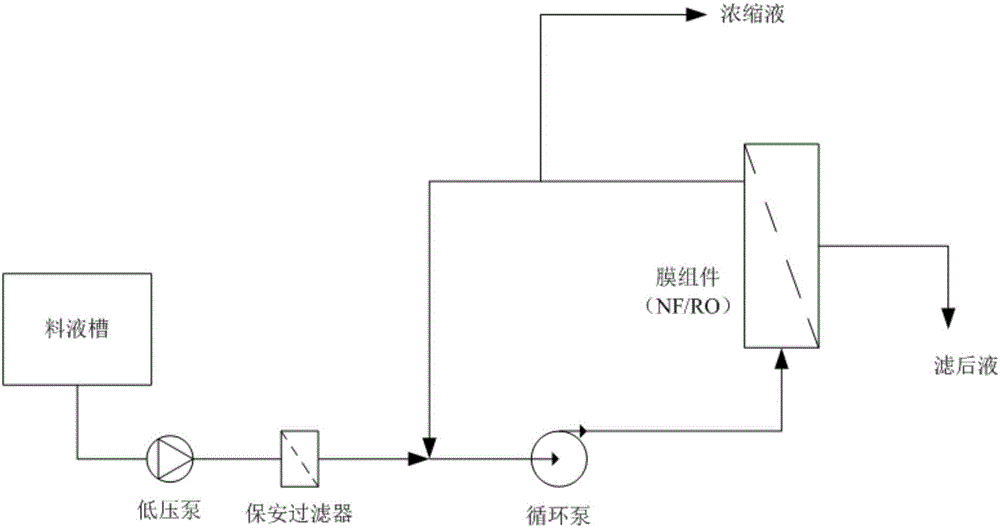

[0040] 3) Membrane concentration: the lithium sulfate solution obtained in step 1) is utilized to carry out membrane concentration by a nanofiltration membrane made of polyamide, the nanofil...

Embodiment 2

[0045] A kind of enrichment process for the production of sulfuric acid lithium salt, comprises the following steps:

[0046] 1) Softening pretreatment: use resin to alternately adsorb calcium and magnesium ions in the raw solution to obtain a lithium sulfate leaching solution with a total content of calcium and magnesium ions of 0.52 mg / L.

[0047] 2) Membrane filtration: the lithium sulfate leaching solution obtained in step 1) is utilized for membrane filtration by a microfiltration membrane made of polyvinylidene fluoride, the microfiltration membrane pore size is 2 μm, and the pressure of the lithium sulfate leaching solution passing through the microfiltration membrane is 0.1MPa , obtaining solid impurity and solid content is 4ppm, lithium ion content is the lithium sulfate solution of 22g / L;

[0048] 3) Membrane concentration: the lithium sulfate solution obtained in step 1) is utilized to carry out membrane concentration by a nanofiltration membrane made of polyamide, ...

Embodiment 3

[0053] A kind of enrichment process for the production of sulfuric acid lithium salt, comprises the following steps:

[0054] 1) Softening pretreatment: use resin to alternately adsorb calcium and magnesium ions in the leaching stock solution to obtain a lithium sulfate leaching solution with a total content of calcium and magnesium ions of 0.43 mg / L.

[0055] 2) Membrane filtration: the lithium sulfate leaching solution obtained in step 1) is utilized to carry out membrane filtration by a microfiltration membrane made of polyacrylonitrile, the microfiltration membrane aperture is 1 μm, and the pressure of the lithium sulfate leaching solution through the microfiltration membrane is 0.1MPa, Obtaining solid impurity and solid content is 3.5ppm, lithium ion content is the lithium sulfate solution of 25g / L;

[0056] 3) membrane concentration: the lithium sulfate solution obtained in step 1) is utilized to carry out membrane concentration by a nanofiltration membrane made of cellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com