A kind of silicon-carbon composite negative electrode material and preparation method thereof

A technology of silicon carbon composite material and negative electrode material, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of silicon negative electrode not being systematically solved, general compatibility, and inability to achieve cycle performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

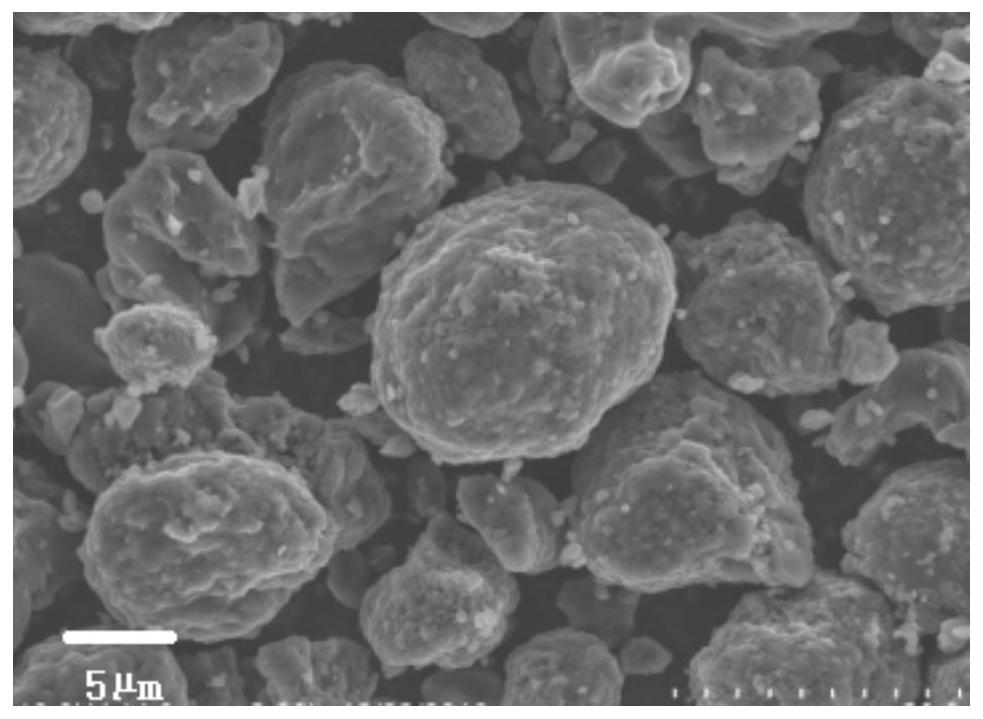

Image

Examples

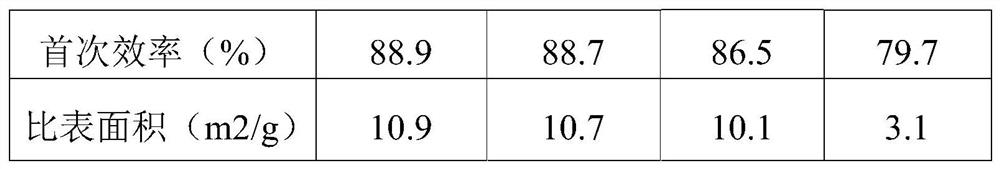

Embodiment 1

[0032] A silicon-carbon composite negative electrode material, the negative electrode material is a core-shell structure, and the core material includes 74-75wt% of a silicon oxide compound, 8.25-11.25wt% of a conductive agent, and 8.25-11.25wt% of titanium dioxide, and the balance is none. Shaped carbon; the shell material includes 98-99 wt% of lithium acetate according to the weight percentage, and the balance is sodium dodecylbenzenesulfonate; the thickness of the shell is 50-500nm.

[0033] The preparation method of the above-mentioned silicon-carbon composite negative electrode material comprises the following steps:

[0034] (1) First add 20g trimethyl bromosilane and 3g gamma-aminopropyltriethoxysilane to 300ml of N-methylpyrrolidone organic solvent and mix evenly, then add 3g carbon nanotubes and 3g titanium dioxide, and carry out Wet ball milling, the ball milling speed is 500 rpm, the time is 12h, and then carbonized at 800°C for 6h under an argon atmosphere to obtai...

Embodiment 2

[0037]A silicon-carbon composite negative electrode material, the negative electrode material is a core-shell structure, and the core material includes 67.5-74.25wt% of silicon oxide compound, 7.5-8.25wt% of conductive agent, 7.5-8.25wt% of titanium dioxide, and the balance is Amorphous carbon; the shell material includes 98-99 wt% of lithium acetate according to the weight percentage, and the balance is sodium dodecylbenzenesulfonate; the thickness of the shell is 50-500nm.

[0038] The preparation method of the above-mentioned silicon-carbon composite negative electrode material comprises the following steps:

[0039] (1) Add 10g of triethylchlorosilane and 1g of γ-(2,3-glycidoxy)propyltrimethoxysilane to 100ml of carbon tetrachloride organic solvent and mix well, then add 1g of vapor deposited carbon fiber and 1g of titanium dioxide, and perform wet ball milling at a speed of 500 rpm for 12 hours, and then carbonize at 780°C for 6 hours under an argon atmosphere to obtain a...

Embodiment 3

[0042] A silicon-carbon composite negative electrode material, the negative electrode material is a core-shell structure, and the core material includes 75-82.5wt% of silicon oxide compound, 11.25-12.375wt% of conductive agent, 11.25-12.375wt% of titanium dioxide, and the balance is Amorphous carbon; the shell material includes 98-99 wt% of lithium acetate according to the weight percentage, and the balance is sodium dodecylbenzenesulfonate; the thickness of the shell is 50-500nm.

[0043] The preparation method of the above-mentioned silicon-carbon composite negative electrode material comprises the following steps:

[0044] (1) After adding 30g dimethyldichlorosilane and 5g gamma-(methacryloyloxy)propyltrimethoxysilane to 500ml xylene organic solvent and mixing evenly, then add 5g graphene and 5g titanium dioxide, and carry out Wet ball milling, the ball milling speed is 500 rpm, the time is 12h, and then carbonized at 820°C for 6h under an argon atmosphere to obtain a silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com