Biofilm filler for livestock and poultry breeding wastewater treatment and its preparation process

A technology of livestock and poultry breeding wastewater and biofilm, applied in the field of biofilm filler for livestock and poultry wastewater treatment and its preparation process, and biofilm filler, can solve the problem of specific surface area, poor compressive strength, good biocompatibility, biophase Poor capacity and other problems, to achieve the effect of large compressive strength, large specific surface area, and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

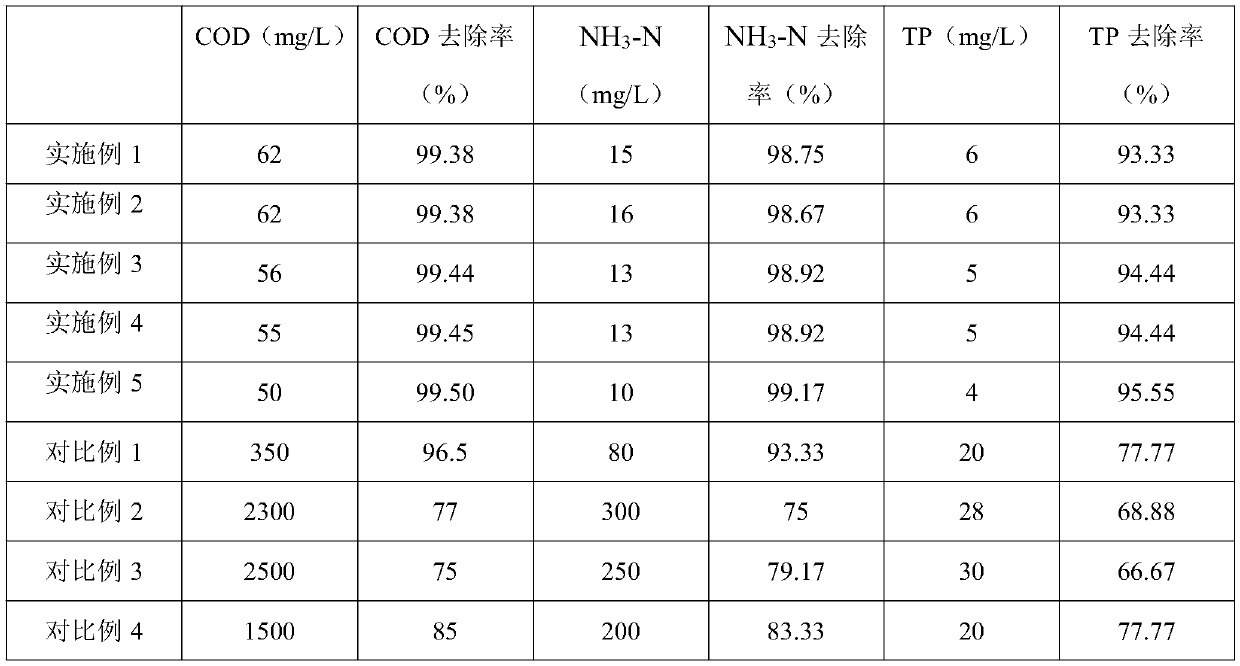

Examples

Embodiment 1

[0029] The biofilm filler for livestock and poultry breeding wastewater treatment of the present invention has a density of 0.96g / cm 3 , is made of the following components: high-density polyethylene 58kg, montmorillonite 10kg, powdered activated carbon 10kg, light calcium carbonate 11kg, shellac resin 3kg, gelatin 1.5kg, cerium sulfate 0.5kg, fullerene 0.5kg .

[0030] The shellac resin particle diameter is 10 orders

[0031] The preparation method of above-mentioned biofilm filler, comprises the steps:

[0032] (1) the lac resin of formula quantity is dissolved in dehydrated alcohol, makes the ethanolic solution of lac resin;

[0033] (2) add the fullerene of formula quantity, fully ball mill;

[0034] (3) In the solution after the ball milling process, add high-density polyethylene, montmorillonite, powdered activated carbon, light calcium carbonate, gelatin and cerium sulfate in a formula amount, 750W microwave treatment for 3 minutes, and ultrasonic oscillation for 1 h...

Embodiment 2

[0037] The biofilm filler for livestock and poultry breeding wastewater treatment of the present invention has a density of 0.98g / cm 3 , is made of the following components: high-density polyethylene 62kg, montmorillonite 18kg, powdered activated carbon 18kg, light calcium carbonate 20kg, lac resin 5kg, gelatin 3kg, cerium sulfate 1kg, fullerene 0.8kg.

[0038] The shellac resin particle diameter is 20 orders

[0039] The preparation method of above-mentioned biofilm filler, comprises the steps:

[0040] (1) the lac resin of formula quantity is dissolved in dehydrated alcohol, makes the ethanolic solution of lac resin;

[0041] (2) add the fullerene of formula quantity, fully ball mill;

[0042] (3) In the solution after the ball milling process, add high-density polyethylene, montmorillonite, powdered activated carbon, light calcium carbonate, gelatin and cerium sulfate in a formula amount, 750W microwave treatment for 3 minutes, and ultrasonic oscillation for 1 hour;

[0...

Embodiment 3

[0045] The biofilm filler for livestock and poultry breeding wastewater treatment of the present invention has a density of 0.96g / cm 3 , is made of the following components: high-density polyethylene 60kg, montmorillonite 17kg, powdered activated carbon 12kg, light calcium carbonate 18kg, lac resin 3kg, gelatin 3kg, cerium sulfate 0.5kg, fullerene 0.8kg.

[0046] The shellac resin particle diameter is 35 orders

[0047] The preparation method of above-mentioned biofilm filler, comprises the steps:

[0048](1) the lac resin of formula quantity is dissolved in dehydrated alcohol, makes the ethanolic solution of lac resin;

[0049] (2) add the fullerene of formula quantity, fully ball mill;

[0050] (3) In the solution after the ball milling process, add high-density polyethylene, montmorillonite, powdered activated carbon, light calcium carbonate, gelatin and cerium sulfate in a formula amount, 750W microwave treatment for 3 minutes, and ultrasonic oscillation for 1 hour;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com