Hardening-preventing microorganism coated fertilizer

A microbial coating, anti-caking technology, applied in the direction of layered/coated fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problems of uneven spots on the surface of fertilizers, microbial stimulation, complex production processes, etc., to reduce fertilizer costs. , reproduction promotion, enhance the effect of photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of the microbial coating fertilizer A of embodiment 1 anti-hardening

[0031] Mix 14.3kg anti-hardening oil, 1.2kg carbon powder, 1.6kg urea, and 2kg potassium humate evenly, and heat to boiling to obtain an anti-hardening agent; mix 1.5kg feather protein powder, 2.7kg stone powder, and 0.8kg strain (The ratio of effective viable bacteria of Bacillus subtilis, Bacillus megaterium and Bacillus jelly-like is: 55:44:53, and the effective viable bacteria of described bacterial agent is 6.5 billion / gram.) Mix evenly, make bag film agent.

[0032] Add 500kg of nitrogen, phosphorus and potassium compound fertilizer (15-5-15) into the coating machine, and then spray 3kg of anti-caking agent evenly on the surface of the fertilizer in the coating machine while it is hot. The compound fertilizer of hardening agent: 3kg coating agent is added in the above-mentioned compound fertilizer containing hardening agent, after 5min, the anti-hardening microbial coated ferti...

Embodiment 2

[0033] The preparation of the microbial coating fertilizer B of embodiment 2 anti-hardening

[0034] With 15kg anti-hardening oil, 1.5kg carbon powder, 3kg urea, 2.5kg potassium humate, mix evenly, heat to boiling, make anti-hardening agent; 1.3kg feather protein powder, 2.4kg stone powder, 1.3kg bacterial classification ( The ratio of effective live bacteria of Bacillus subtilis, Bacillus megaterium and jelly-like Bacillus is: 48:50:51, and the effective number of viable bacteria of the bacterial agent is 5.5 billion / gram.) Mix evenly to prepare coating agent.

[0035] Add 500kg of nitrogen, phosphorus and potassium compound fertilizer (15-5-15) into the coating machine, and then spray 3.5kg of anti-caking agent evenly on the surface of the fertilizer in the coating machine while it is hot. The compound fertilizer of anti-caking agent; 3kg coating agent is added in the above-mentioned compound fertilizer containing compacting agent, after 5 minutes, the anti-caking microbial...

Embodiment 3

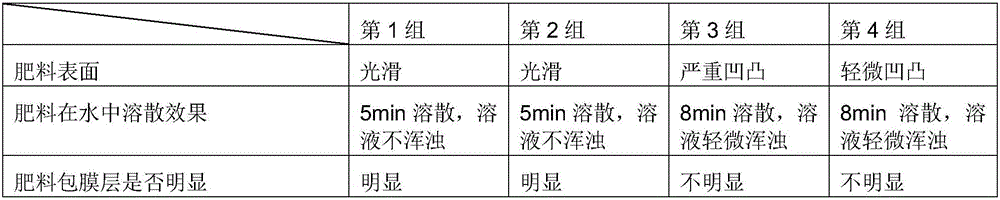

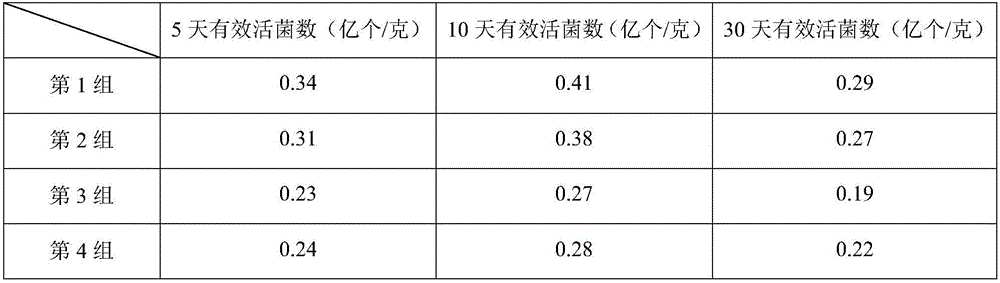

[0036] Embodiment 3 compares the preparation of anti-caking microbial coating fertilizer

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com