Technique for synthesizing zinc stearate from glyceryl tristearate

A technology of tristearic acid and zinc stearate, which is applied in the chemical industry, can solve the problems of short production cycle of zinc stearate, high content of free fatty acid, and poor color of the product, and achieve low raw material cost, improve purity, and ensure The effect of chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

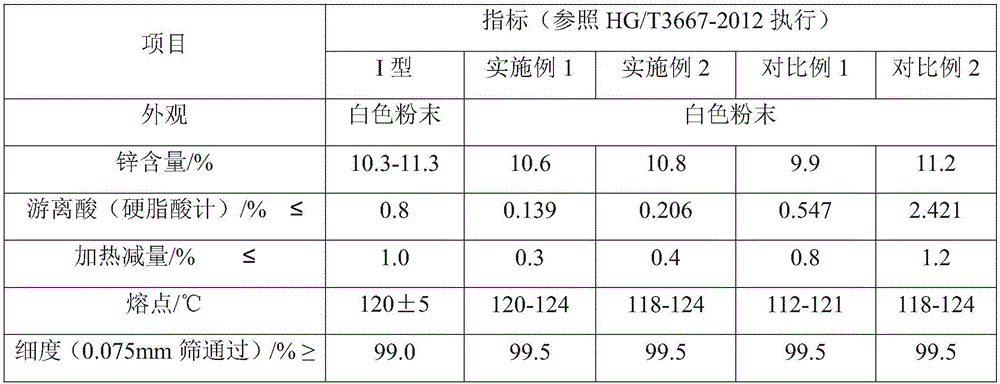

Examples

Embodiment 1

[0025] S1: Take tristearin, stir while feeding, keep the temperature at 100°C, add catalyst A, antioxidant and water after the tristearin is completely melted, at a temperature of 135°C and a pressure of 0.7MPa Carry out hydrolysis reaction under the condition of condition, hydrolyzate stands still 45min, oil and water are separated, and oil phase pressure filtration reclaims catalyst and promptly obtains stearic acid;

[0026] Wherein, by mass ratio, in catalyst A, zinc oxide: Al 2 o 3 -MgO is 1:6, its dosage is 4% of the mass of glyceryl tristearate, Al 2 o 3 -MgO is prepared by precipitation method, in molar ratio, Al 2 o 3 :MgO is 2.5:1;

[0027] In terms of mass ratio, in antioxidants, antioxidant 1076: antioxidant DLTDP: antioxidant T501 is 0.12: 0.38: 1, and its consumption is 0.5% of tristearin quality;

[0028] By mass ratio, glyceryl tristearate: water is 1: 0.45;

[0029] S2: Add the stearic acid in S1 into the zinc stearate reaction kettle, keep the temperat...

Embodiment 2

[0035]S1: Take tristearin, stir while feeding, keep the temperature at 100°C, add catalyst A, antioxidant and water after the tristearin is completely melted, at a temperature of 120°C and a pressure of 0.8MPa Carry out hydrolysis reaction under the condition of certain conditions, hydrolyzate is left standstill 40min, oil and water are separated, and oil phase pressure filtration reclaims catalyst and promptly obtains stearic acid;

[0036] Wherein, by mass ratio, in catalyst A, zinc oxide: Al 2 o 3 -MgO is 1:4, its dosage is 5.5% of the mass of glyceryl tristearate, Al 2 o 3 -MgO is prepared by precipitation method, in molar ratio, Al 2 o 3 :MgO is 2:1;

[0037] In terms of mass ratio, in antioxidants, antioxidant 1076: antioxidant DLTDP: antioxidant T501 is 0.15: 0.32: 1, and its consumption is 0.3% of tristearin quality;

[0038] By mass ratio, glyceryl tristearate: water is 1: 0.5;

[0039] S2: Add the stearic acid in S1 into the zinc stearate reaction kettle, keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com