Preparation method of chitosan aerogel

A technology of chitosan and airgel, which is applied in the field of preparation of chitosan airgel, can solve the problems of low specific surface area and poor gel performance of chitosan gel, and achieve low equipment requirements and easy availability of raw materials , highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

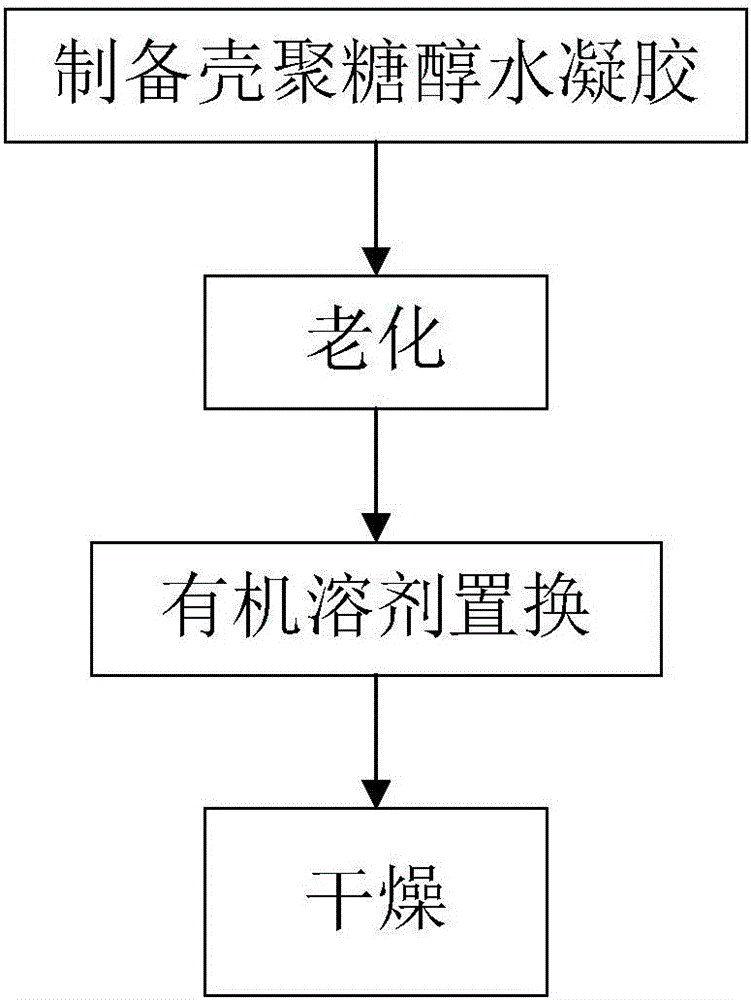

[0021] see figure 1 , the invention provides a kind of preparation method of chitosan airgel, comprising the following steps:

[0022] 1) Preparation of chitosan alcohol hydrogel: dissolving chitosan in an ethanol water solvent to obtain a chitosan solution with a concentration of 3 to 10 g / L, then adding a cross-linking agent solution dissolved in ethanol, stirring and standing Obtain chitosan alcohol hydrogel;

[0023] 2) After the chitosan alcohol hydrogel is aged, the mature chitosan alcohol hydrogel is obtained, and the ethanol water solvent in the mature chitosan alcohol hydrogel is replaced with an organic solvent for 1 to 3 days, and the chitosan is obtained by drying Aerogel;

[0024] The ethanol-water solvent is formed by mixing ethanol and 2wt.% acetic acid aqueous solution in a volume ratio of 30-60:40-70.

[0025] The ethanol-water solvent herein refers to a binary solvent system formed by mixing ethanol and 2wt.% acetic acid aqueous solution by volume ratio. ...

Embodiment 1

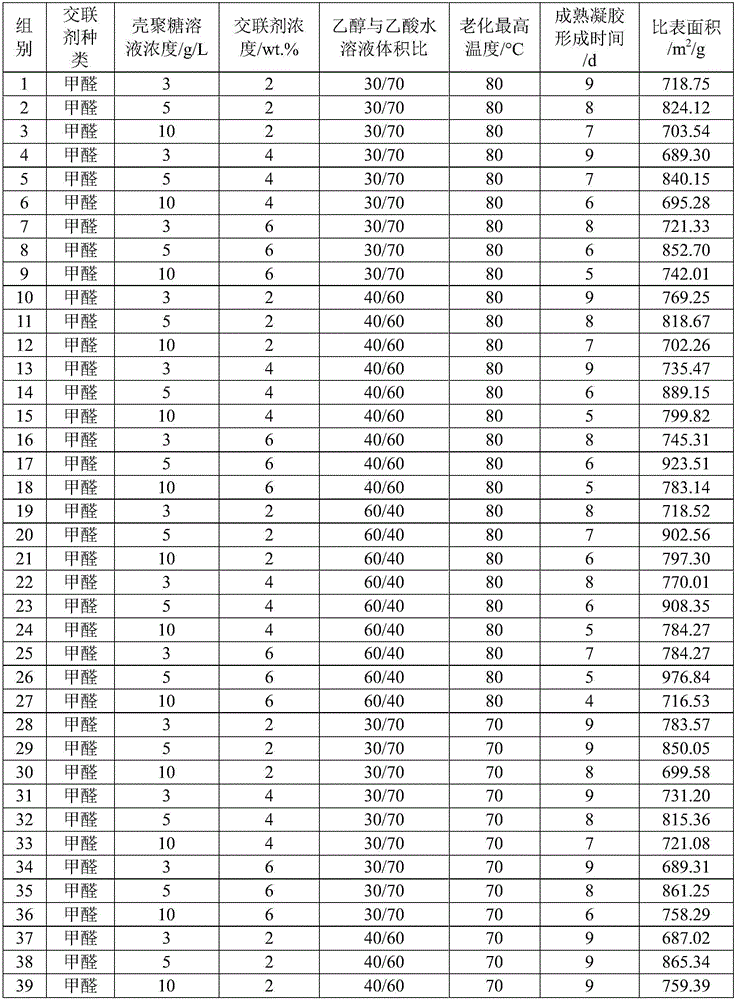

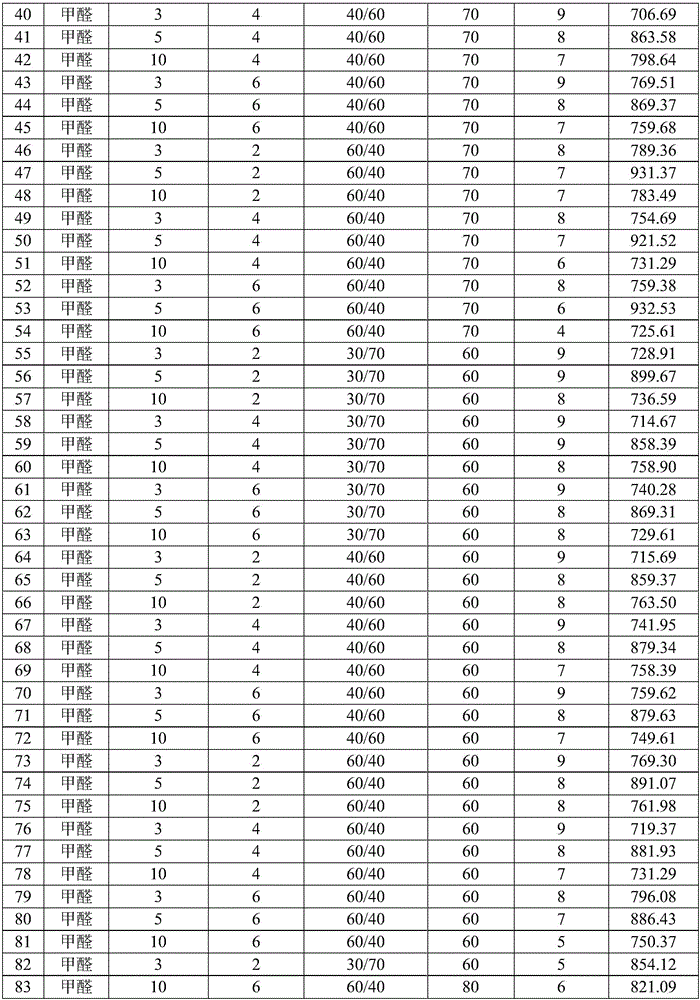

[0039] Take by weighing 1g chitosan and dissolve in the solvent system (100mL) that ethanol / 2wt.% acetic acid aqueous solution volume ratio is 30 / 70, add the 4% formaldehyde cross-linking agent solution of 100mL after stirring at room temperature for 1 hour at 5 ℃ Stir for 10 minutes and leave to stand for 30 minutes to obtain the initial chitosan alcohol hydrogel; place the resulting initial chitosan alcohol hydrogel in a constant temperature aging tank, start at an initial temperature of 10°C at a heating rate of 10°C / d Aging until 80°C, and then insulated for 1 day to obtain mature chitosan alcohol hydrogel; the ethanol water solvent in the mature chitosan alcohol hydrogel was replaced with ethanol solvent for 2 days to obtain chitosan alcohol gel, and finally in Carbon dioxide supercritical drying was carried out at 55°C and 14MPa to obtain chitosan airgel.

Embodiment 2

[0041] (1) chitosan is dissolved in the binary solvent system to form the initial chitosan solution, then stir at room temperature and add cross-linking agent ethanol solution in the chitosan solution of the above-mentioned alcohol-water binary solvent system, and finally Stir at low temperature, obtain initial chitosan alcohol hydrogel after leaving standstill;

[0042]Ethanol and 2wt.% acetic acid aqueous solution are mixed by volume ratio: 30:70 to form a binary solvent system; the initial chitosan solution concentration is 3g / L; the crosslinking agent concentration is 2wt.%. The crosslinking agent is one of formaldehyde, acetaldehyde and glutaraldehyde or any combination of more than one; the low temperature condition is 1°C.

[0043] (2) Place the obtained initial chitosan alcohol hydrogel in a constant temperature aging tank, start aging at an initial temperature of 10°C at a heating rate of 10°C / d until 60°C, and finally heat it for 1 day to obtain mature chitosan alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com