A kind of sponge rubber midsole material with fruit wood fragrance and preparation method thereof

The technology of sponge rubber and fruit wood is applied in the field of sponge rubber midsole material and its preparation, which can solve the problem of not involving the deodorization function of midsole material for shoes, etc., so as to reduce the risk of harmful bacteria, reduce weight, and improve personal image. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The formula is (parts by mass):

[0066] 5# standard glue 100, sulfur 2.2, accelerator M 0.8, accelerator DM 0.6, accelerator D 0.15, antioxidant SP-C1.5, zinc oxide 4, stearic acid 4.25, salicylic acid 3, AK foaming agent 2. Baking soda 8, naphthenic oil 23.5, fruit wood powder 50.

[0067]Wherein, the mass content of camphor wood powder in the fruit wood powder is 80%, the mass content of apple tree powder is 20%, and the particle size of the fruit wood powder is 120 mesh, which is prepared by the following steps:

[0068] 1) collect camphor wood, apple tree branches and trunks with a diameter of 20-30 cm, and initially dry them to ensure that the surface is dry;

[0069] 2) Use a wood shredder for primary crushing, the size of the crushed sawdust is 5-6cm, and the thickness is <2mm;

[0070] 3) drying the sawdust after the first crushing, the mass water content of the dried sawdust is less than 10%;

[0071] 4) The dried sawdust enters the wood powder grinder for ...

Embodiment 2

[0083] The formula is (parts by mass):

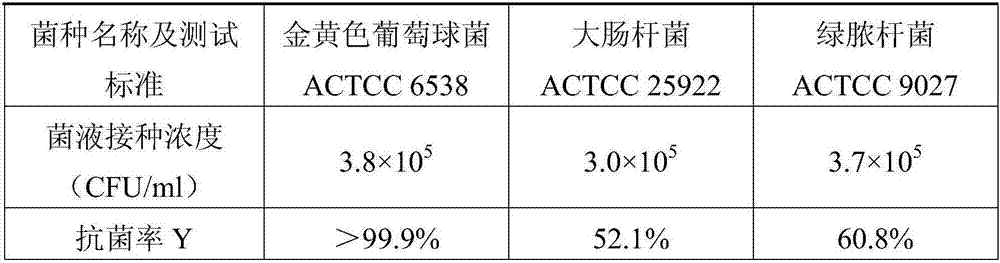

[0084] 5# standard glue 100, sulfur 2.4, accelerator M 0.9, accelerator DM 0.6, accelerator D 0.2, antioxidant SP-C1.5, zinc oxide 4.2, stearic acid 4.5, salicylic acid 3, AK foaming agent 2. Baking soda 8, naphthenic oil 24, fruit wood powder 45, nano silver powder 1.

[0085] Wherein, the mass content of camphor wood powder in the fruit wood powder is 90%, the mass content of pear tree powder is 10%, and the particle size of the fruit wood powder is 100 mesh, which is prepared by the following steps:

[0086] 1) collecting camphor wood, pear branches and trunks with a diameter of 20-30 cm, and preliminary drying to ensure that the surface is dry;

[0087] 2) Use a wood shredder for primary crushing, the size of the crushed sawdust is 5-6cm, and the thickness is <2mm;

[0088] 3) Drying the sawdust after the initial crushing, the mass water content of the dried sawdust is less than 10%;

[0089] 4) The dried sawdust enters the wood ...

Embodiment 3

[0095] The formula is (parts by mass):

[0096] 5# standard glue 100, sulfur 2.5, accelerator M 1, accelerator DM 0.6, accelerator D 0.2, antioxidant SP-C1.5, zinc oxide 4.5, stearic acid 4.8, salicylic acid 3.2, AK foaming agent 2 , baking soda 8, naphthenic oil 24, fruit powder 40, organic aromatic guanidine antibacterial agent XT-11 (Shanghai Xinte Textile Material Research Center Co., Ltd.) 2.

[0097] Wherein, the mass content of camphor wood powder in the fruit wood powder is 85%, the mass content of apple tree powder is 10%, the mass content of pear tree powder is 5%, and the particle size of fruit wood powder is 100 mesh, which is prepared by the following steps:

[0098] 1) collecting diameters of camphor wood, pear branches and trunks and apple tree branches and trunks with a diameter of 20 to 30 cm is initially dried to ensure that the appearance is dry;

[0099] 2) Use a wood shredder for primary crushing, the size of the crushed sawdust is 5-6cm, and the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com