Electromagnetic shielding material used for power supply equipment, and preparation method thereof

A technology for electromagnetic shielding materials and power supply equipment, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problem that the anti-electromagnetic interference ability cannot meet the application requirements, and achieve the effect of simple preparation method and excellent shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An electromagnetic shielding material for power equipment, prepared from the following raw materials in parts by weight: 40 parts of POM, 35 parts of EVA, 18 parts of neoprene, 12 parts of polyaniline, 10 parts of conductive filler, 5 parts of aluminum sulfate, ten parts 4 parts of brominated diphenyl ether, 8 parts of diethyl phthalate, 5 parts of methyl silicone oil, 28 parts of ethanol, 2 parts of coupling agent;

[0021] The conductive filler is a mixture of molybdenum powder, nano gadolinium trioxide, zinc powder, aramid fiber and indium tin oxide powder in a weight ratio of 4:1:2:3:1. The coupling agent is dodecyltrimethoxysilane.

[0022] The preparation method of the above-mentioned electromagnetic shielding material for power equipment is characterized in that it comprises the following steps:

[0023] 1) Mix and stir the conductive filler, methyl silicone oil, coupling agent and ethanol at 86°C for 90 minutes;

[0024] 2) Then add POM, EVA, polyaniline, and ...

Embodiment 2

[0027] An electromagnetic shielding material for power equipment, prepared from the following raw materials in parts by weight: 55 parts of POM, 42 parts of EVA, 24 parts of neoprene, 18 parts of polyaniline, 15 parts of conductive filler, 8 parts of aluminum sulfate, ten parts 6 parts of brominated diphenyl ether, 11 parts of diethyl phthalate, 7 parts of methyl silicone oil, 35 parts of ethanol, 3.5 parts of coupling agent;

[0028] The conductive filler is a mixture of molybdenum powder, nano gadolinium trioxide, zinc powder, aramid fiber and indium tin oxide powder in a weight ratio of 4:1:2:3:1. The coupling agent is distearoyloxy isopropoxy aluminate.

[0029] The preparation method of the above-mentioned electromagnetic shielding material for power equipment is characterized in that it comprises the following steps:

[0030] 1) Mix and stir the conductive filler, methyl silicone oil, coupling agent and ethanol at 86°C for 90 minutes;

[0031] 2) Then add POM, EVA, pol...

Embodiment 3

[0034] An electromagnetic shielding material for power equipment, prepared from the following raw materials in parts by weight: 70 parts of POM, 50 parts of EVA, 30 parts of neoprene, 24 parts of polyaniline, 20 parts of conductive filler, 12 parts of aluminum sulfate, decabromo 8 parts of diphenyl ether, 14 parts of diethyl phthalate, 10 parts of methyl silicone oil, 45 parts of ethanol, 5 parts of coupling agent;

[0035] The conductive filler is a mixture of molybdenum powder, nano gadolinium trioxide, zinc powder, aramid fiber and indium tin oxide powder in a weight ratio of 4:1:2:3:1. The coupling agent is a mixture of perfluorodecyltrichlorosilane and distearoyloxyisopropoxyaluminate, and the weight ratio of the two is 4:3.

[0036] The preparation method of the above-mentioned electromagnetic shielding material for power equipment is characterized in that it comprises the following steps:

[0037] 1) Mix and stir the conductive filler, methyl silicone oil, coupling age...

PUM

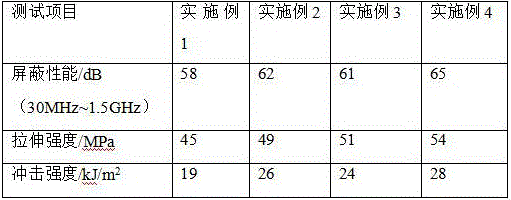

| Property | Measurement | Unit |

|---|---|---|

| Shielding effectiveness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com