Cold area garage-type dry biogas fermentation system and working method thereof

A biogas fermentation and dry-type technology, which is applied in the field of garage-type dry biogas fermentation systems in cold regions, can solve problems such as high construction costs, uneven heating of fermentation raw materials, and low-energy and stable operation of dry-process biogas projects. The effect of heat transfer rate and thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

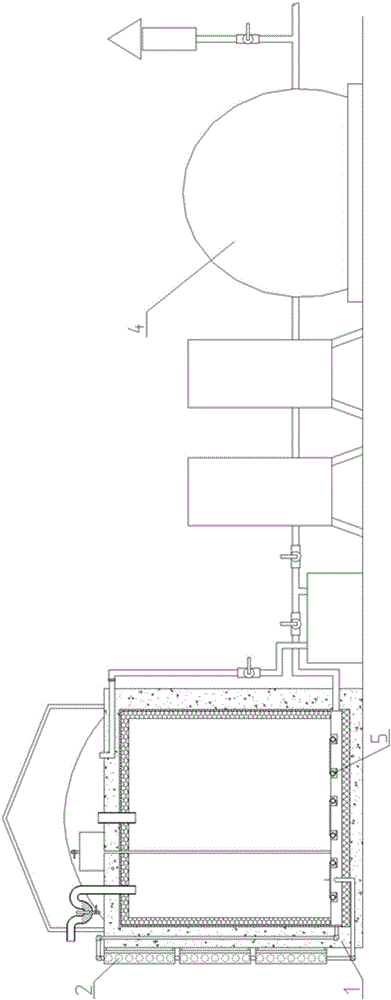

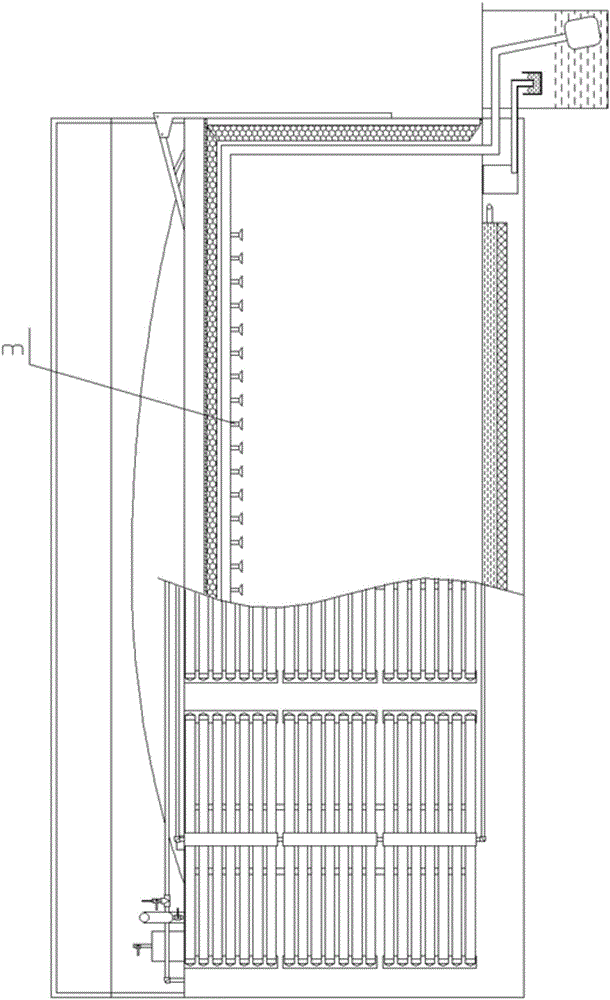

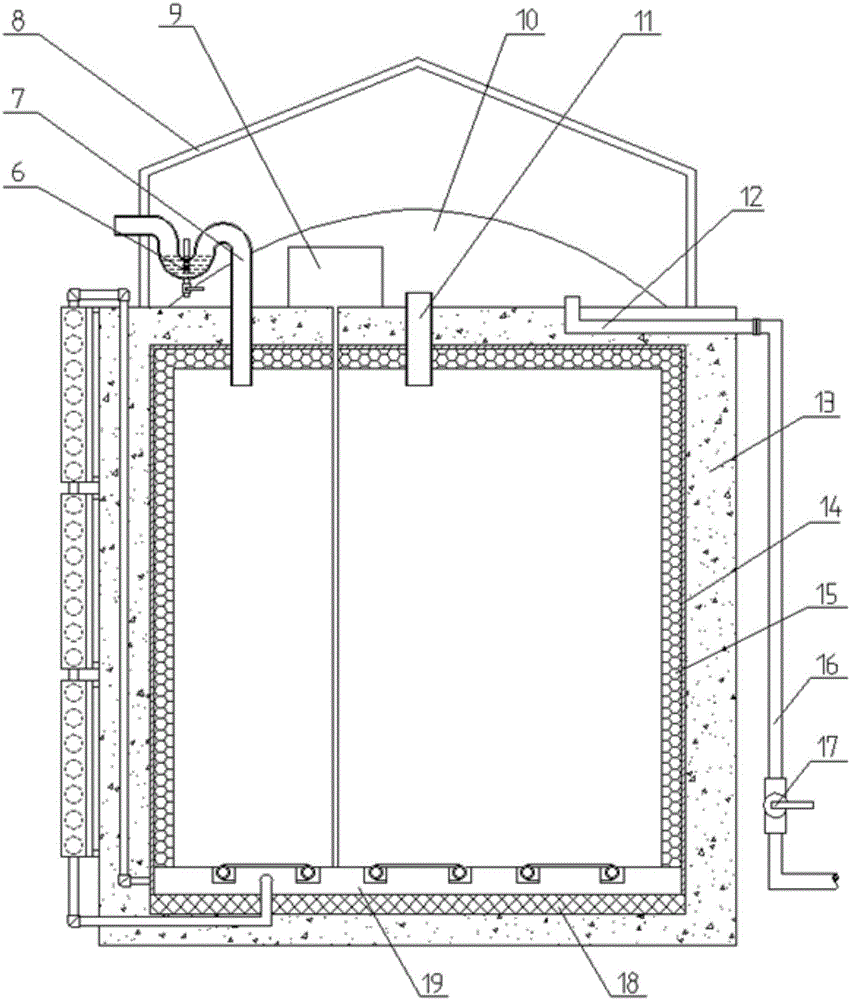

[0055] As shown in the figure, a garage-type dry biogas fermentation system in a cold area is characterized by including a fermentation tank 1, a solar heating system 2, a biogas slurry spray system 3, a biogas purification storage system 4 and an aeration system 5,

[0056] Described fermentation tank 1 comprises: water seal valve 6, emptying pipe 7, solar panel greenhouse 8, gas-collecting film 10, ventilation pipe 11, first air outlet pipe 12, reinforced concrete tank body 13, macromolecule sealing waterproof layer 14 , polyurethane insulation layer 15, the first air pipe 16, the first shut-off valve 17, the hydraulic door 57, the fermenter 1 is designed as a rectangular tank structure, the tank is arranged on the horizontal ground, and arranged according to the east-west direction, it is a fermenter The main part of the system; the reinforced concrete tank 13 is a hollow cuboid structure, the reinforced concrete tank 13 is arranged on the level ground and one side of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com