A method for preparing sulfur-doped graphene film

A technology of sulfur-doped graphene and graphene, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problems of increasing the preparation process of doped graphene film, and achieve large-scale industrial production , strong operability, simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

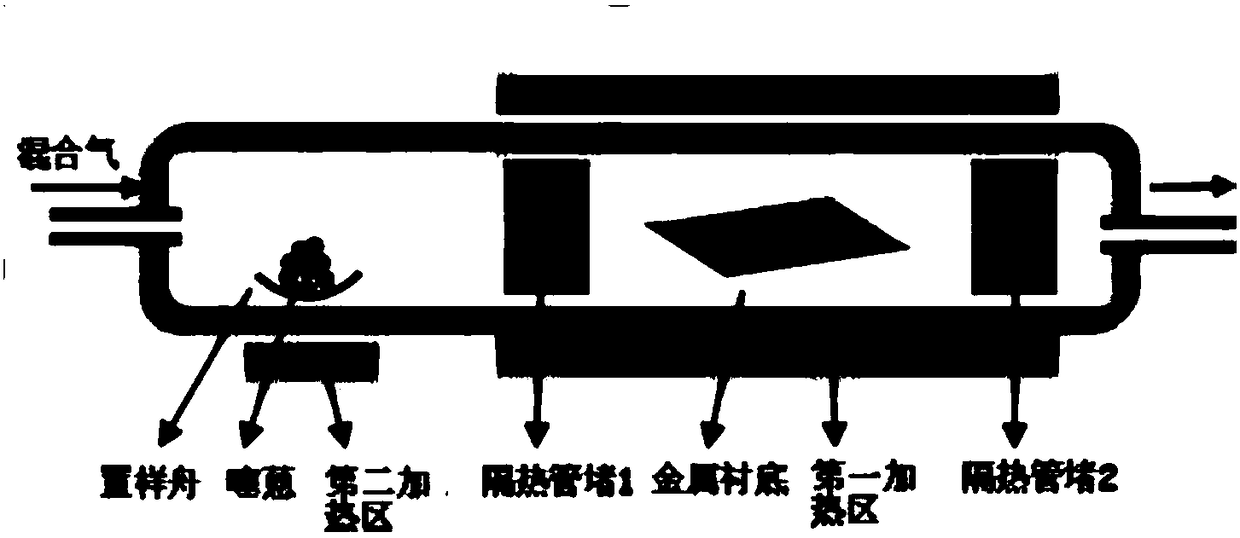

[0036] Step A: Wash the copper foil with a thickness of 25 microns and an area of 10 cm × 10 cm with 30% dilute hydrochloric acid, deionized water, and absolute ethanol in sequence, each cleaning time is 5 minutes, and finally use Blow dry with nitrogen; figure 1As shown, the cleaned copper foil is placed in the central temperature zone of the reaction chamber of the chemical vapor deposition system, and the central temperature zone of the reaction chamber of the chemical vapor deposition system is used as the first heating zone, and 200 mg of thianthrene is weighed and placed in the In the sample boat, the sample boat is placed at the front end of the first heating zone, and is insulated from the first heating zone, and the sample boat is heated by a heating belt, and the heating belt is used as the second heating zone;

[0037] Step B: Use a mechanical pump to pump the pressure of the reaction chamber of the chemical vapor deposition system to 5 Pa, and then introduce a mi...

Embodiment 2

[0044] Step A: Wash the copper foil with a thickness of 25 microns and an area of 10 cm × 10 cm with 30% dilute hydrochloric acid, deionized water, and absolute ethanol in sequence, each cleaning time is 5 minutes, and finally use Blow dry with nitrogen; figure 1 As shown, the cleaned copper foil is placed in the central temperature zone of the reaction chamber of the chemical vapor deposition system, and the central temperature zone of the reaction chamber of the chemical vapor deposition system is used as the first heating zone, and 100 mg of thianthrene is weighed and placed in the In the sample boat, the sample boat is placed at the front end of the first heating zone, and is insulated from the first heating zone, and the sample boat is heated by a heating belt, and the heating belt is used as the second heating zone;

[0045] Step B: Use a mechanical pump to pump the pressure of the reaction chamber of the chemical vapor deposition system to 5 Pa, and then introduce a m...

Embodiment 3

[0052] Step A: Wash the copper foil with a thickness of 25 microns and an area of 50 cm × 20 cm with 30% dilute hydrochloric acid, deionized water, and absolute ethanol in sequence, each cleaning time is 5 minutes, and finally use Blow dry with nitrogen; figure 1 As shown, the cleaned copper foil is placed in the central temperature zone of the reaction chamber of the chemical vapor deposition system, and the central temperature zone of the reaction chamber of the chemical vapor deposition system is used as the first heating zone, and 100 mg of thianthrene is weighed and placed in the In the sample boat, the sample boat is placed at the front end of the first heating zone, and is insulated from the first heating zone, and the sample boat is heated by a heating belt, and the heating belt is used as the second heating zone;

[0053] Step B: Use a mechanical pump to pump the pressure of the reaction chamber of the chemical vapor deposition system to 5 Pa, and then feed a mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com