Beam lead capacitor processing method

A beam-type lead wire and processing method technology, which is applied to fixed capacitor parts, fixed capacitor electrodes, fixed capacitor dielectrics, etc., can solve the problems of complex processing, difficult silicon etching, and high production costs, and achieve reduction in process flow, The effect of improving processing efficiency and reducing the difficulty of substrate etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

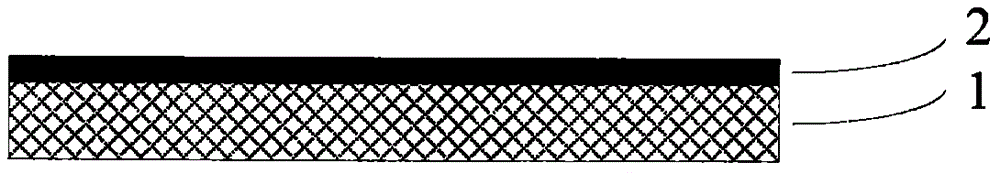

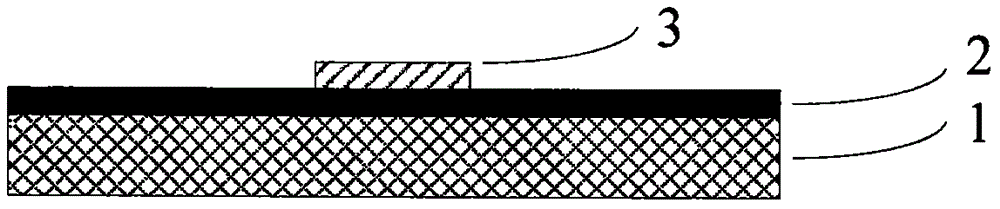

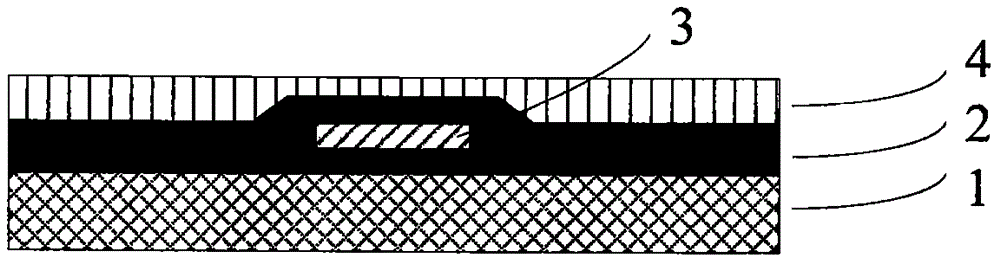

[0030] A method for processing a beam-type lead capacitor provided by the present invention mainly includes: the first step, selecting a nickel plate 1 with a thickness of 0.1 mm as a mechanical support, and forming a layer of TiW metal film 2 on the nickel plate by sputtering coating method , the schematic diagram of the structure is as figure 1 As shown; in the second step, the polyimide dielectric film is covered 3 to cover the entire nickel plate 1 by spin coating, and then the required graphics are retained by photolithography. The schematic diagram of the structure is as follows figure 2 As shown; in the third step, a layer of TiW / Au metal layer structure is formed by sputtering coating method, covering the existing polyimide dielectric film 3, and the metal layer structure formed on the nickel plate is TiW-Au, and the structural diagram is as follows image 3 As shown, wherein the mass ratio of titanium to tungsten is 1:9; the fourth step is to apply glue on the substr...

Embodiment 2

[0032] The processing method of a beam-type lead capacitor provided by the present invention mainly includes: the first step, select a nickel plate 1 with a thickness of 0.5 mm as a mechanical support, and form a layer of TiW metal film 2 on the nickel plate by sputtering coating method , the schematic diagram of the structure is as figure 1 As shown; in the second step, the polyimide dielectric film is covered 3 to cover the entire nickel plate 1 by spin coating, and then the required graphics are retained by photolithography. The schematic diagram of the structure is as follows figure 2 As shown; in the third step, a layer of TiW / Au metal layer structure is formed by sputtering coating method, covering the existing polyimide dielectric film 3, and the metal layer structure formed on the nickel plate is TiW-Au, and the structural diagram is as follows image 3 As shown, wherein the mass ratio of titanium to tungsten is 1:9; the fourth step is to apply glue on the substrate, ...

Embodiment 3

[0034] The processing method of a kind of beam-type lead capacitor provided by the present invention mainly comprises: the first step, selects the nickel plate 1 of 1mm thickness as mechanical support, and adopts the sputter coating method to form a layer of TiW metal film 2 on the nickel plate, Structural diagram such as figure 1 As shown; in the second step, the polyimide dielectric film is covered 3 to cover the entire nickel plate 1 by spin coating, and then the required graphics are retained by photolithography. The schematic diagram of the structure is as follows figure 2 As shown; in the third step, a layer of TiW / Au metal layer structure is formed by sputtering coating method, covering the existing polyimide dielectric film 3, and the metal layer structure formed on the nickel plate is TiW-Au, and the structural diagram is as follows image 3 As shown, wherein the mass ratio of titanium to tungsten is 1:9; the fourth step is to apply glue on the substrate, pre-baking,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com