Nickel hydroxide/graphene roll-carbon nano-tube composite carbon aerogel, preparation thereof and application thereof

A carbon nanotube composite and acidified carbon nanotube technology, which is applied in the manufacture of hybrid/electric double layer capacitors, electrical components, hybrid capacitor electrodes, etc., can solve problems such as limiting performance, achieve uniform distribution, simple preparation process, good electrical The effect of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

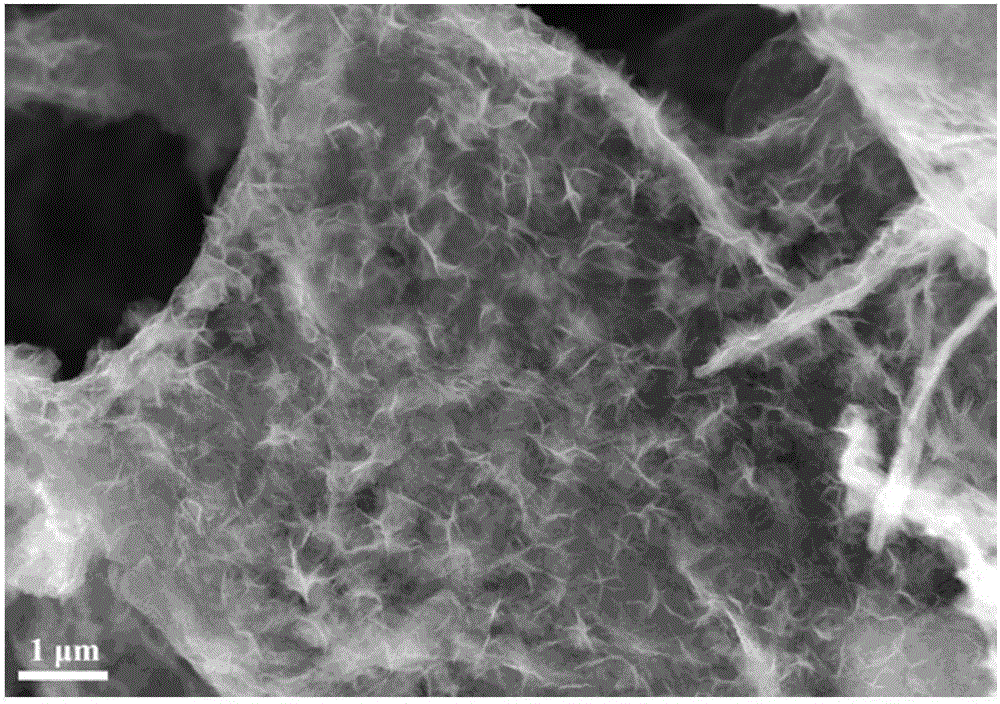

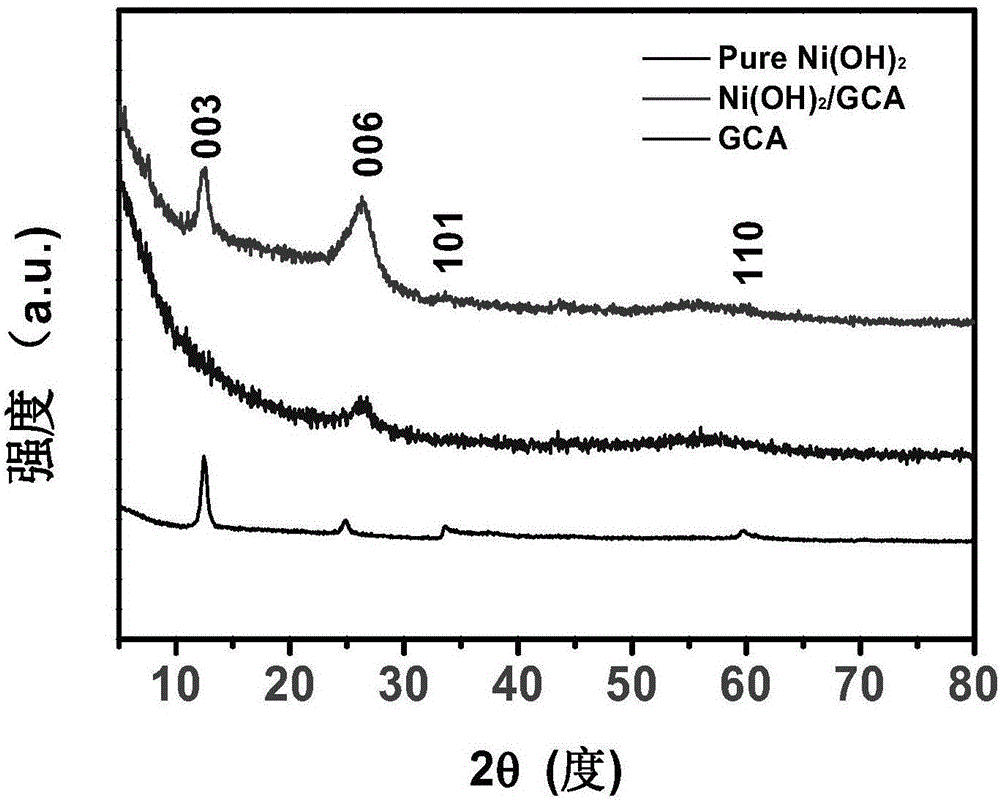

[0036] (1) Disperse graphite oxide in deionized water, and obtain 8mg mL by ultrasonic -1 Stable dispersed graphene oxide dispersion;

[0037] (2) Disperse the acidified carbon nanotubes in deionized water, and obtain 4mg mL by ultrasonic -1 Stable dispersed graphene oxide dispersion;

[0038] (3) 10mL 8mg mL -1 Graphene oxide dispersion and 10mL 4mg mL -1 The acidified carbon nanotube dispersion is mixed, and after ultrasonication, a uniform dispersion is formed;

[0039] (4) Place the mixed solution of step (3) gained in the mold and freeze in liquid nitrogen for 20min;

[0040](5) freeze-dry the composite material obtained in step (4) in a freeze-drying machine, the freeze-drying temperature is -30°C, the vacuum is 10Pa, and the freeze-drying time is 20h to form a graphene oxide roll-carbon nanotube composite gas gel;

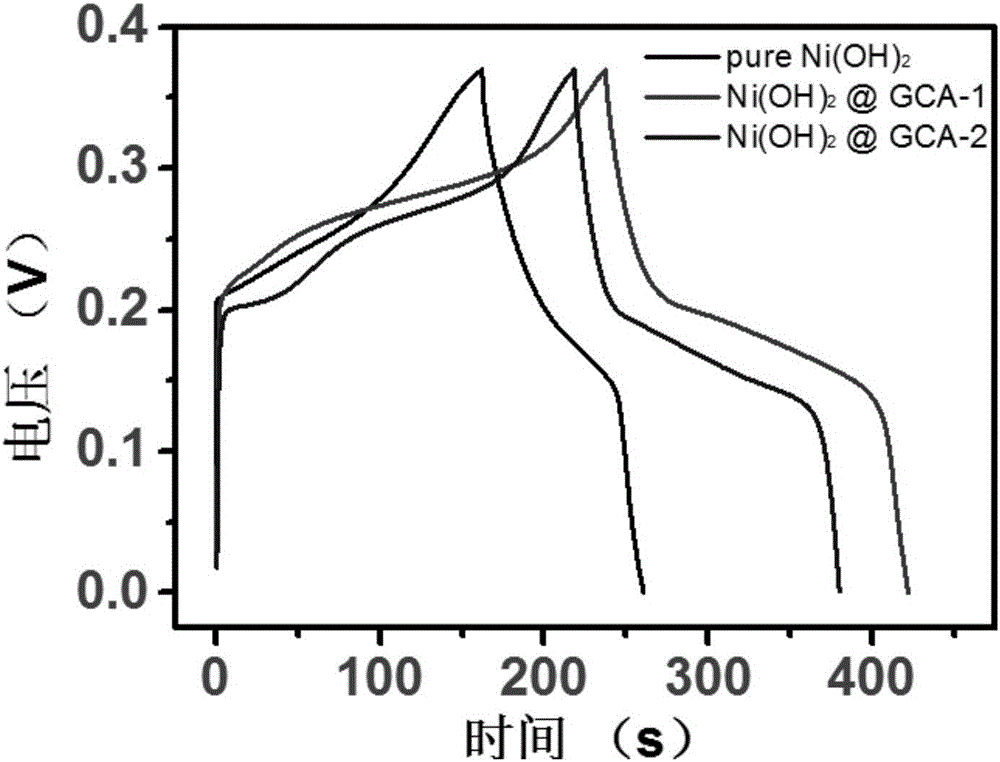

[0041] (6) Carry out high-temperature carbonization of the airgel obtained in step (5) in a nitrogen atmosphere, the carbonization temperature is 700 ...

Embodiment 2

[0047] (1) Disperse graphite oxide in deionized water, and obtain 8mg mL by ultrasonic -1 Stable dispersed graphene oxide dispersion;

[0048] (2) Disperse the acidified carbon nanotubes in deionized water, and obtain 4mg mL by ultrasonic -1 Stable dispersed graphene oxide dispersion;

[0049] (3) 10mL 8mg mL -1 Graphene oxide dispersion and 10mL 4mg mL -1 The acidified carbon nanotube dispersion is mixed, and after ultrasonication, a uniform dispersion is formed;

[0050] (4) Place the mixed solution of step (3) gained in the mold and freeze in liquid nitrogen for 20min;

[0051] (5) freeze-dry the composite material obtained in step (4) in a freeze-drying machine, the freeze-drying temperature is -30°C, the vacuum is 10Pa, and the freeze-drying time is 20h to form a graphene oxide roll-carbon nanotube composite gas gel;

[0052] (6) Carry out high-temperature carbonization of the airgel obtained in step (5) in a nitrogen atmosphere, the carbonization temperature is 700...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com