A process for removing urea from water

A urea, hydration technology, applied in chemical instruments and methods, water pollutants, natural water treatment, etc., can solve the problems of insufficient reaction, urea dispersion, high capital and operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

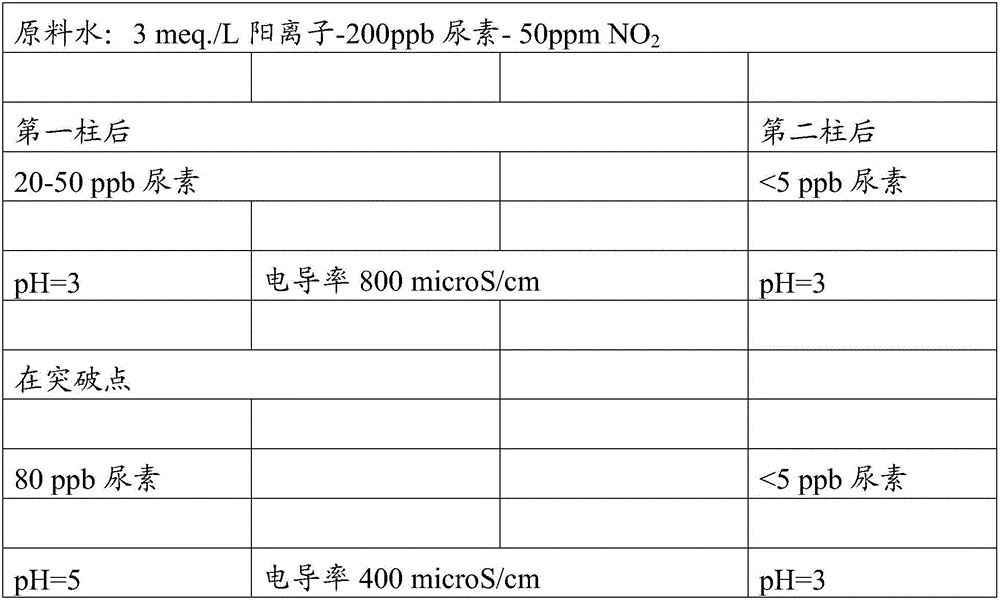

[0009] More specifically, the improved method of the present invention includes one or two cation exchange columns connected in series, each packed with a strongly acidic cation exchange resin type R-SO 3 -H+ (polystyrene cross-linked with DVB). The ion exchange resin is loaded with cations (calcium, magnesium, sodium, potassium, ammonium, etc.) derived from the raw water and replaced with hydronium ions (H+).

[0010] Before the method of the present invention enters one or more cation exchange containers, or before entering each container, add nitrite ion (NO 2 -), which as NaNO 2 (sodium nitrite) salt, nitrous acid (HNO 2 ) or NO 2 gas. NO 2 The molar ratio to urea should be 50 to 1500, ideally 100 to 700. The reaction that takes place on the strong anion exchange resin is:

[0011] CO(NH 2 ) 2 +HNO 2 +H + —>N 2 +CO 2 +NH 4 + +H 2 o

[0012] Ammonium (NH 4 + ) was captured on the ion exchange resin. The produced gas CO 2 and N 2 Soluble in water under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com