Preparation method of nitrite ion colorimetric sensing cellulose material

A nitrite ion, colorimetric sensing technology, applied in the direction of chemical reaction of materials, material analysis by observing the influence of chemical indicators, etc., can solve the problem of inability to detect trace anions, difficult to popularize and use , low sensitivity and other problems, to achieve the effect of good selectivity, low price and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

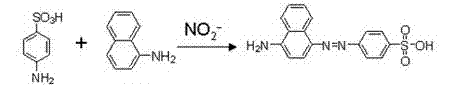

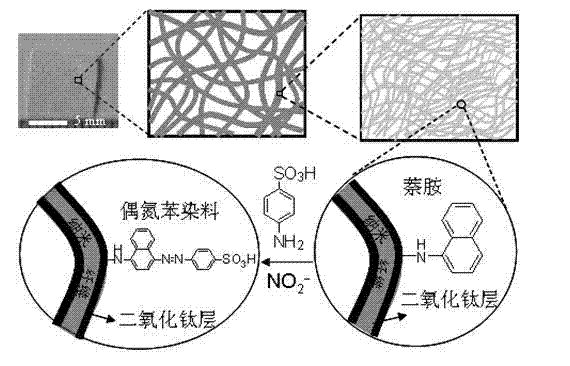

[0060] Embodiment 1: Prepare anionic colorimetric sensing cellulose material with the method provided by the invention, and use this material to sense nitrite ions in aqueous solution:

[0061] Firstly, the anionic colorimetric sensing cellulose material in the present invention is prepared.

[0062] 1) Prepare a 100 mM tetrabutyl titanate solution, the solvent is toluene / ethanol (v:v=1:1), and stir at room temperature for 1 hour.

[0063]2) Put ordinary quantitative filter paper (produced by Hangzhou Xinhua Co., Ltd., Zhejiang Province) in a suction filtration device, rinse it with ethanol for 2 to 3 times, and dry it with air flow. Take 10 mL of tetrabutyl titanate solution and add it to the suction filtration device, and let it stand for 3 minutes to deposit tetrabutyl titanate on the filter paper fibers.

[0064] 3) Slowly filter the tetrabutyl titanate solution under low vacuum. When the liquid level of the solution is close to the surface of the filter paper, add ethano...

Embodiment 2

[0072] Embodiment 2: Prepare anion colorimetric sensing cellulose material with the method provided by the present invention, and use this material to detect other anions in aqueous solution:

[0073] Firstly, the anionic colorimetric sensing cellulose material in the present invention is prepared.

[0074] According to the preparation method and steps of Example 1, an anion colorimetric sensing cellulose material modified with a monolayer of naphthylamine molecules was obtained, and used for the detection of other anions.

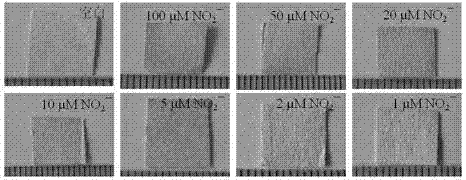

[0075] Anionic colorimetric sensing cellulose material of self-assembled naphthylamine molecular monolayer was exposed to 1 mM mixture of different anions (fluoride, chloride, bromide, acetate, nitrate) and sulfanilic acid In the aqueous solution for 15 minutes, after taking it out, wash with water to remove physically adsorbed anions, and dry at room temperature. It can be found that even when the concentration of other anions is as high as 1 mM, it stil...

Embodiment 3

[0076] Embodiment 3: Anion colorimetric sensing cellulose material is prepared by the method provided by the present invention, and this material is used to detect NO in nitrite aqueous solution containing different cations 2 ? :

[0077] Firstly, the anionic colorimetric sensing cellulose material in the present invention is prepared.

[0078] According to the preparation method and steps of Example 1, an anion colorimetric sensing cellulose material modified with a monolayer of naphthylamine molecules was obtained, and it was used for the detection of nitrite containing different cations.

[0079] The anionic colorimetric sensing cellulose material of the self-assembled naphthylamine molecular monolayer was placed in 100 μM NaNO 2 or KNO 2 and p-aminobenzenesulfonic acid mixed aqueous solution for 15 min, after taking it out, wash with water to remove physically adsorbed nitrite ions, and dry at room temperature. It can be found that after reacting with different nitrite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com