Humic acid composition and preparation method thereof

A composition and technology of humic acid, applied in the field of humic acid, can solve the problems of no technical inspiration, poor water solubility of the medium, and easy formation of flocculent precipitation, etc., to achieve the ability to promote absorption and utilization, not easy to flocculate, and resist hard water strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

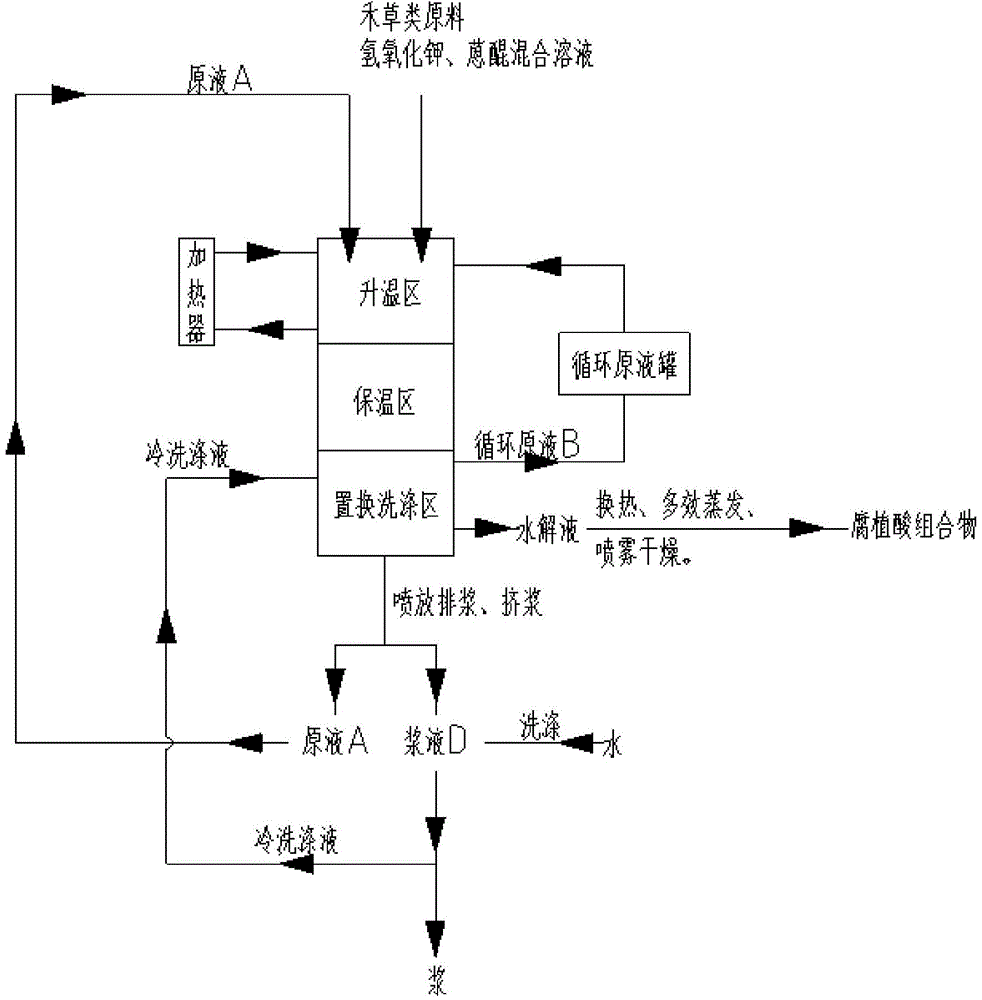

Method used

Image

Examples

Embodiment 1

[0048] (1) Take wheat straw, rice straw, corn stalk, sorghum, and reed respectively, and crush them to obtain grass slices with a length of 60 mm. Wash and remove sediment from the grass slices, dehydrate until the absolute dry matter content is greater than 15%, and add screw feed Compress and continue to dehydrate to obtain grass raw materials with a dry matter content of 35-45%;

[0049] (2) Mix the mixed solution of grass raw materials, potassium hydroxide and anthraquinone, and the stock solution A, and then continuously add them to the reactor, while continuously circulating the stock solution B at 175°C. The amount of potassium hydroxide is the dry matter of the grass raw materials 22% of the mass, the amount of anthraquinone is 0.06% of the absolute dry matter of the grass raw material, the consumption of the mixed solution of potassium hydroxide and anthraquinone+stock solution A+circulating stock solution B is 6.5 times of the absolute dry matter of the grass raw mate...

Embodiment 2

[0060] (1) Take wheat straw, rice straw, corn stalk, sorghum, and reed respectively, and crush them to obtain grass slices with a length of 60 mm. Wash and remove sediment from the grass slices, dehydrate until the absolute dry matter content is greater than 15%, and add screw feed Compress and continue to dehydrate to obtain grass raw materials with a dry matter content of 35-45%;

[0061] (2) Mix the mixed solution of grass raw materials, potassium hydroxide and anthraquinone, and the stock solution A, and then continuously add them to the reactor, while continuously circulating the stock solution B at 150°C. 28% of the mass, the amount of anthraquinone is 0.1% of the absolute dry matter of grass raw materials, the consumption of the mixed solution of potassium hydroxide and anthraquinone+stock solution A+circulating stock solution B is 6.5 times of the absolute dry matter of grass raw materials, The pressure inside the reactor is 0.6MPa;

[0062] (3) The temperature in the...

Embodiment 3

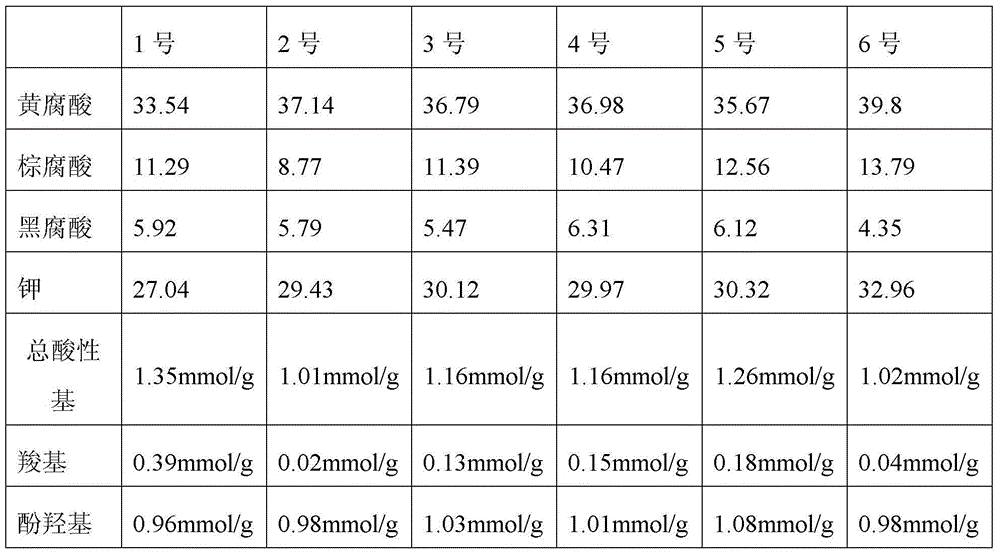

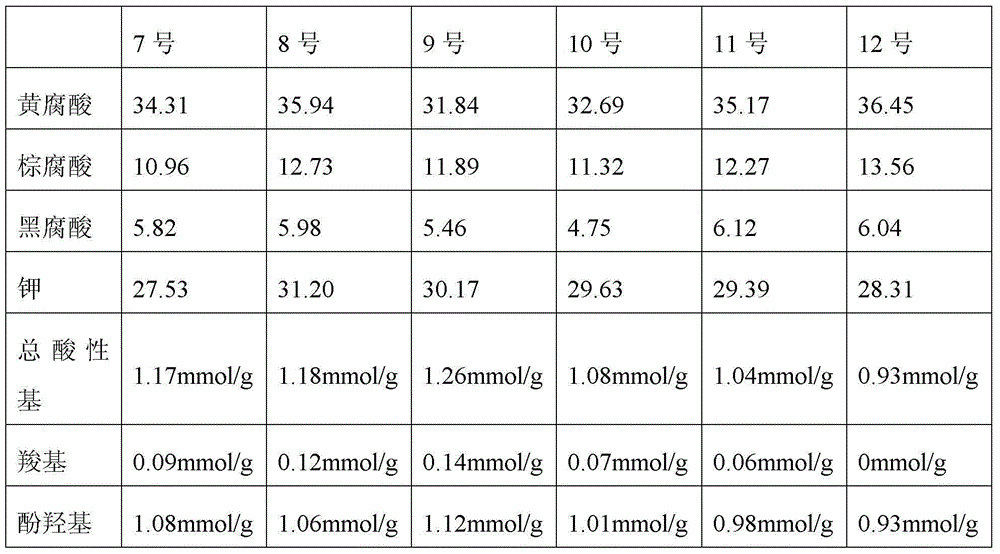

[0071] (1) Take the 1:1 mixture of wheat straw and straw, the 1:1 mixture of wheat straw and corn stalk, the 1:1 mixture of straw and corn stalk, the 1:1 mixture of corn stalk and sorghum, the 1:1 mixture of sorghum and reed, straw, A 1:1:1 mixture of corn stalks and sorghum, respectively numbered 1-6, crushed to obtain grass pieces with a length of 40mm, washed to remove sediment, and dehydrated until the absolute dry matter content is greater than 15%. Add the screw feeder to compress and continue to dehydrate to obtain grass raw materials with a dry matter content of 35-45%;

[0072] (2) Mix the mixed solution of grass raw materials, potassium hydroxide and anthraquinone, and the stock solution A, and then continuously add them to the reactor, while continuously circulating the stock solution B at 150°C. 26% of the mass, the amount of anthraquinone is 0.08% of the absolute dry matter of grass raw materials, the consumption of the mixed solution of potassium hydroxide and an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com