Preparation method and application of magnetic hierarchical porous carbon material

A technology of multi-level pores and carbon materials, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems that single-pore structure carbon materials cannot meet high-performance applications, and achieve good Effect of magnetic separation performance and reproducibility, short process and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

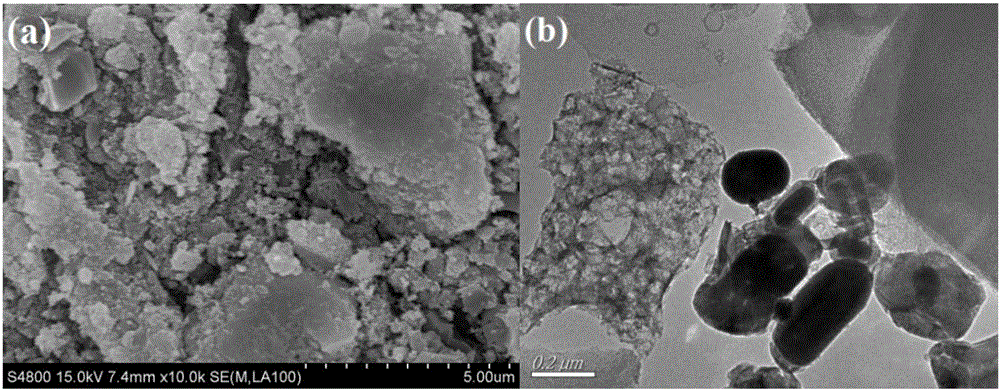

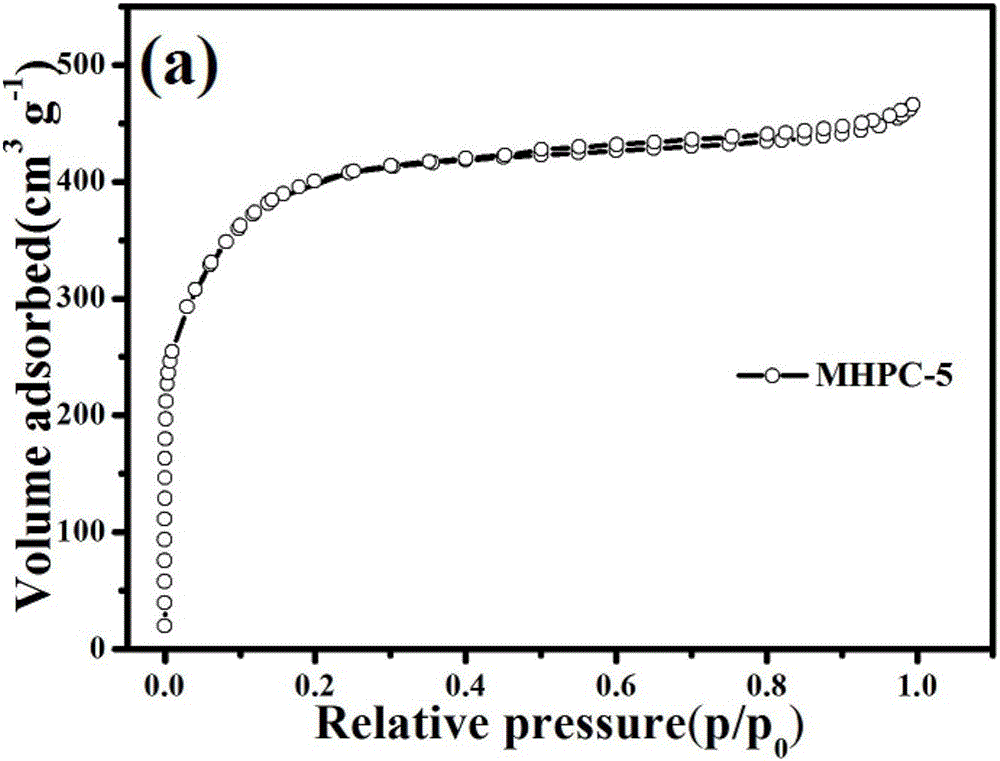

[0026] Fully grind 4.0g of ferric nitrate and 20g of tripotassium ethylenediaminetetraacetic acid salt, take 15g of sample and simultaneously carbonize and activate it in a tube furnace at a temperature of 750°C and a heating rate of 3°C min -1 , maintained for 1.0 h; the obtained product was washed several times with a mixture of ethanol and distilled water, vacuum filtered, washed with water until neutral, and dried to obtain a magnetic hierarchical porous carbon material.

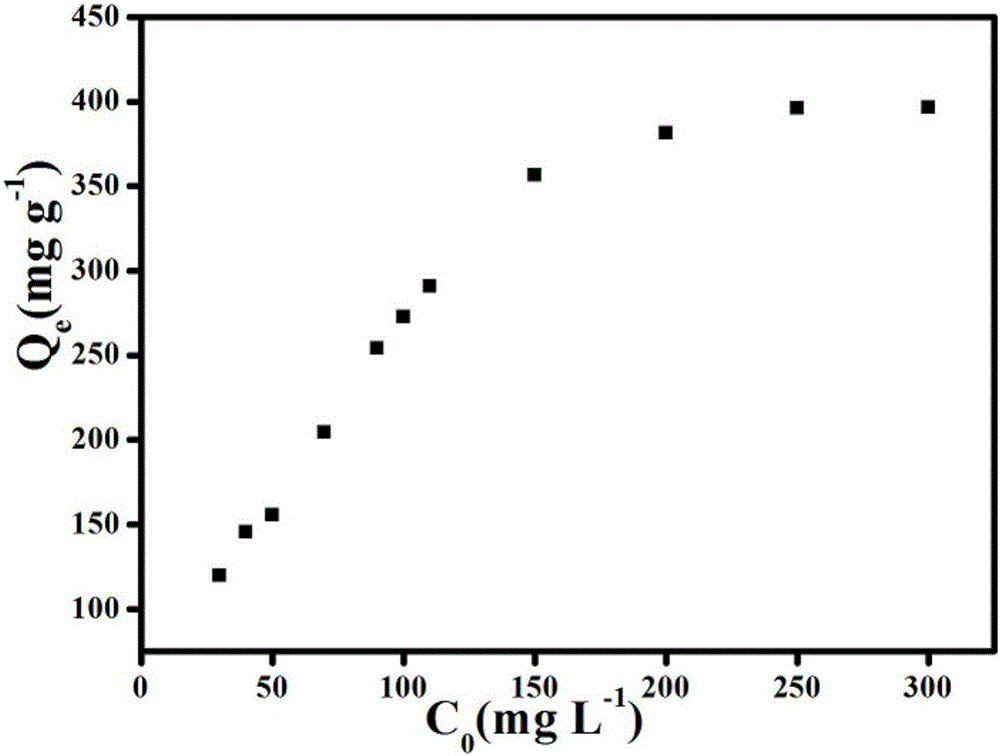

[0027] The static adsorption experiment was completed; 10mL of chloramphenicol solutions of different concentrations were added to the centrifuge tube, and 2.0mg of magnetic hierarchical porous carbon materials were added thereto, and left standing in a constant temperature water bath. The pH value of the solution, the amount of adsorbent, The impact of contact time and temperature on the adsorption of chloramphenicol; after the adsorption reaches saturation, the supernatant is collected by filtration wit...

Embodiment 2

[0037]Fully grind 2.0g ferric nitrate and 20g dipotassium ethylenediaminetetraacetic acid salt, take 15g sample and carbonize and activate it synchronously in a tube furnace at a temperature of 800°C and a heating rate of 5°C min -1 , maintained for 1.0 h; the obtained product was washed several times with a mixture of ethanol and distilled water, vacuum filtered, washed with water until neutral, and dried to obtain a magnetic hierarchical porous carbon material. According to the steps of Example 1, the resulting equilibrium adsorption capacity is 407.7mg g -1 . At an initial concentration of 300mg L -1 , when the temperature is 298K, the adsorption equilibrium is reached in about 400min.

Embodiment 3

[0039] Fully grind 1.0g ferric nitrate and 20g tripotassium ethylenediaminetetraacetic acid salt, take 15g samples and carbonize and activate them synchronously in a tube furnace at a temperature of 850°C and a heating rate of 10°C min -1 , maintained for 2.0 h; the obtained product was washed several times with a mixture of ethanol and distilled water, vacuum filtered, washed with water until neutral, and dried to obtain a magnetic hierarchical porous carbon material. Operated according to the steps of Example 1, the resulting equilibrium adsorption capacity is 444.2mg g -1 . At an initial concentration of 300mg L -1 , when the temperature is 298K, the adsorption equilibrium is reached in about 350min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com