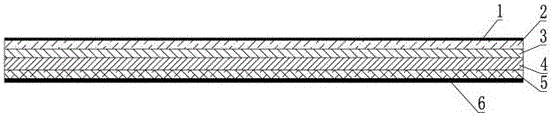

Decorative colorful patterned metal floor and manufacturing method thereof

The technology of a metal floor and a manufacturing method, which is applied in the field of decoration and decoration materials, can solve the problems of easy wear and tear of the metal film layer, highly toxic volatiles, easy deformation and deterioration, etc., and achieve the effects of simple and fast construction, good antibacterial performance and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The 0.1mm thick 304 stainless steel coil is selected as the base material, pre-treated to degrease, and then cleaned and dried.

[0062] Step 1: Substrate Surface Hydroxylation and Microporosity

[0063] Put the cleaned stainless steel base material after the above-mentioned treatment in a place containing chemical composition and concentration respectively: CrO 3 (50g / l) and H 2 SO 4 (100g / l) chemical oxidation solution, chemical oxidation at 85°C for 10 minutes, to form hydroxyl groups and porous oxide film on the surface of the above stainless steel material, so as to greatly enhance the adhesion between the substrate and the upper printing layer and its lower surface Cohesion of layer materials.

[0064] Step 2: Print the decorative layer

[0065] Print a layer of simulated wood grain pattern on the upper surface (front) of one side of the stainless steel substrate treated in step 1 by means of roller continuous offset printing, and dry according to the requirem...

Embodiment 2

[0083] A 0.2mm thick aluminum alloy strip is selected as the base material, and it is pre-treated to degrease, clean and dry.

[0084] Step 1: Substrate Surface Hydroxylation and Microporosity

[0085]Put the cleaned aluminum alloy base material after the above treatment in a chemical solution containing the chemical composition and concentration: NaOH (30g / l), and chemically corrode it for 1min at a temperature of 60°C, forming Hydroxyl groups and porous film layer, so as to greatly enhance the bonding force between the substrate and the upper printing layer and the lower adhesive layer material.

[0086] Step 2: Print the decorative layer

[0087] A layer of simulated wood grain pattern is printed on one side surface (front side) of the above-mentioned aluminum alloy substrate treated in step 1 by means of roller continuous offset printing, and then dried according to the requirements of the ink used.

[0088] Step 3: Coating the surface wear-resistant protective coating ...

Embodiment 3

[0100] The 0.1mm thick 304 stainless steel coil is selected as the substrate, and the pre-treatment is degreasing, cleaning and drying.

[0101] Step 1: Substrate Surface Hydroxylation and Microporosity

[0102] Put the aluminum alloy base material that has been cleaned through the above-mentioned treatment on a place containing chemical composition and concentration respectively: CrO 3 (50g / l) and H 2 SO 4 (100g / l) chemical oxidation solution, chemical oxidation at a temperature of 85°C for 10 minutes, to form hydroxyl groups and a porous oxide film on the surface of the above stainless steel material, so as to greatly strengthen the substrate and its upper printing layer and its lower adhesive layer Material bonding.

[0103] Step 2: Print the decorative layer

[0104] Print a layer of simulated wood grain pattern on one side surface (front) of the stainless steel substrate treated in step (1) by means of roller continuous offset printing, and dry according to the requir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com