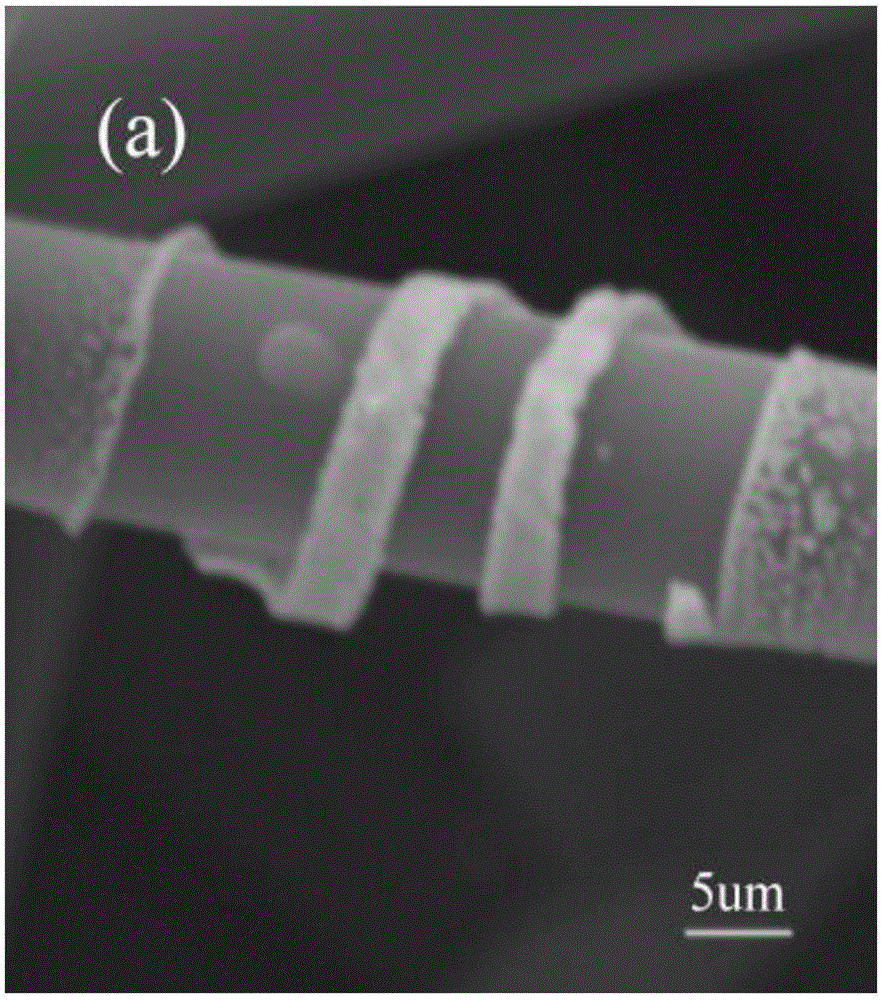

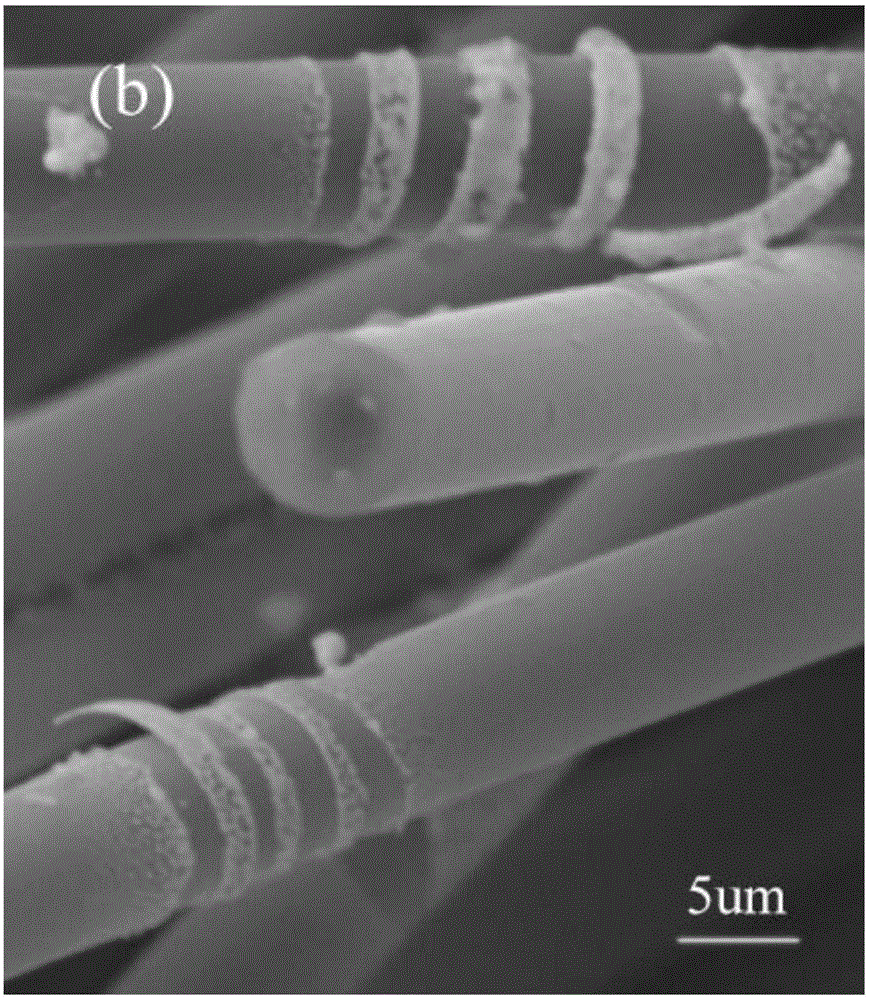

Method using sol-gel method to synthesize spiral ZrC whiskers in in-situ manner

A sol-gel method and in-situ synthesis technology, which is applied in the field of in-situ synthesis of helical ZrC whiskers by sol-gel method, can solve problems not involved in the application of ZrC whiskers, etc., and achieve improved erosion resistance, strength and Toughness, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take 2.5D needle-punched carbon felt (0.43-0.45g / cm 3 ) was cut, sheared and ground into a sample with a size of 70×50×10 mm and a flat surface, and the sample was put into a graphite mold holder and loaded into a CVI furnace. Vacuumize the furnace chamber, then open the argon valve for flushing. Repeat this 3 times; start the temperature and time control program, raise the temperature to 1000°C, the heating rate is 4°C / min, and the heating time is 4h, and the argon gas is supplied for protection, and the argon flow rate is 1500ml / min; when the temperature reaches 1000°C, Open the natural gas valve, set the natural gas flow rate to 80L / h, and set the Ar gas flow rate to 1600ml / min at the same time, and deposit for 1.5h; close the natural gas valve and flow meter, adjust the argon flow rate to 1500ml / min, turn off the power, and naturally Cool to room temperature; close the argon gas valve and flowmeter, and the experiment ends.

[0044] Measure 50mL of ethanol and put...

Embodiment 2

[0047] Take 2.5D needle-punched carbon felt (0.43-0.45g / cm 3 ) was cut, sheared and ground into a sample with a size of 70×50×10 mm and a flat surface, and the sample was put into a graphite mold holder and loaded into a CVI furnace. Vacuumize the furnace chamber, then open the argon valve for flushing. Repeat this 3 times; start the temperature and time control program, raise the temperature to 1000°C, the heating rate is 4°C / min, and the heating time is 4h, and the argon gas is supplied for protection, and the argon flow rate is 1500ml / min; when the temperature reaches 1000°C, Open the natural gas valve, set the natural gas flow rate to 80L / h, and set the Ar gas flow rate to 1600ml / min at the same time, deposit for 2h; close the natural gas valve and flow meter, adjust the argon flow rate to 1500ml / min, turn off the power, and cool naturally to room temperature; close the argon gas valve and flowmeter, and the experiment ends.

[0048] Measure 50mL of ethanol and put it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com