Method for preparing low-ash and low-sulfur coal-water slurry by using coal slurry

A technology of coal water slurry and coal slime, which is applied in the field of clean coal, can solve the problems of poor comprehensive utilization of coal slime, environmental pollution, low utilization efficiency of coal slime, etc., and achieve efficient recovery and utilization, improve product quality, and high recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

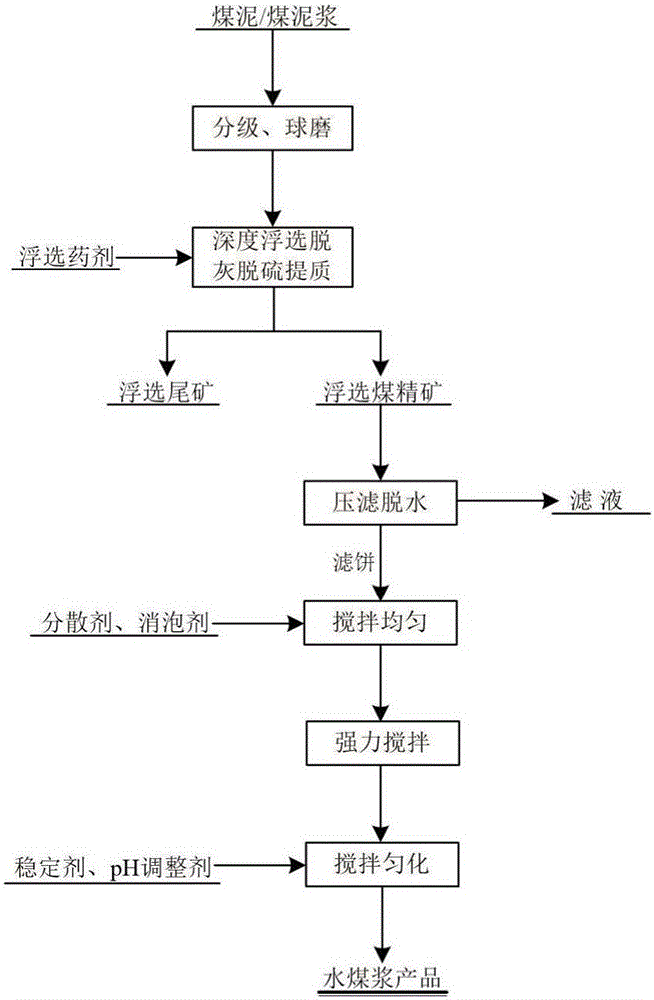

Method used

Image

Examples

Embodiment 1

[0065] The coal slime was taken from a coal washing plant in Panxian County, Guizhou Province (ash content 39.6%, water content 9.5%, sulfur content 0.95%).

[0066] Step (1): Coal Slurry Slurry Treatment

[0067] After the coal slime is slurried with water, it is classified and ball milled to obtain a slurry with a solid content of 50%. The -0.074mm particles in the slurry account for 85% of the total mass of the solid part of the slurry;

[0068] Step (2): Flotation

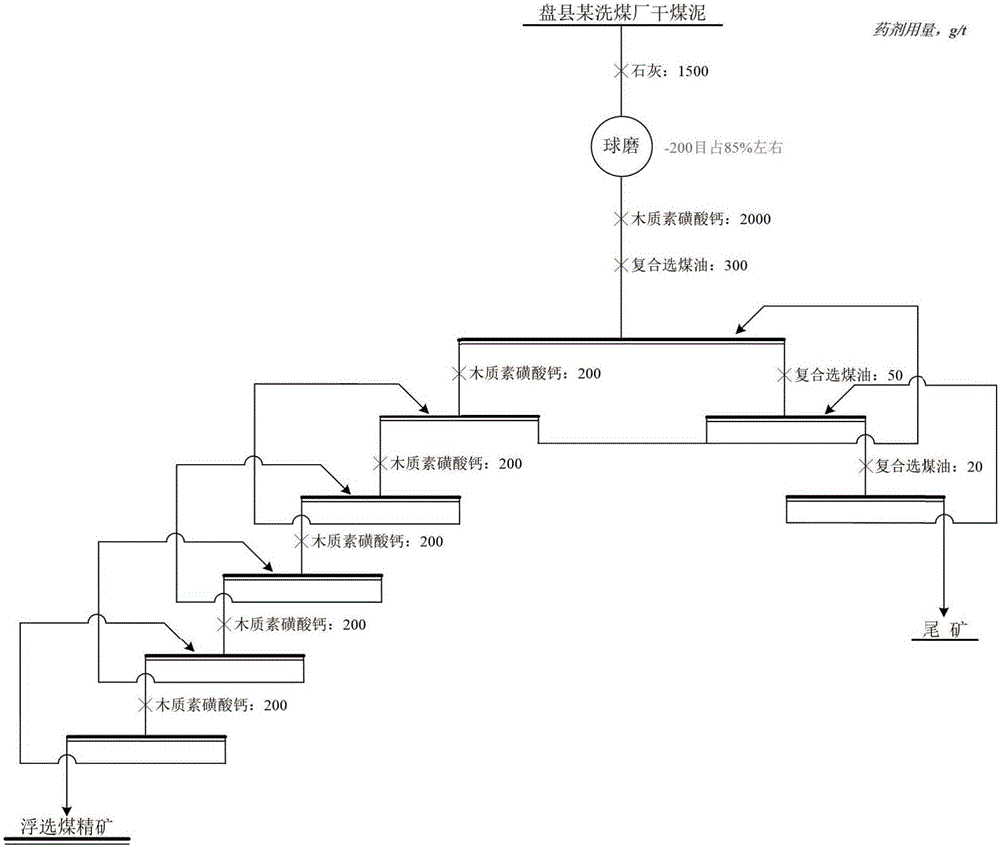

[0069] Add the ore pulp that water adjustment step (1) makes, and the solid content of the ore pulp (addressed ore pulp) after adjustment is 31%, then adds flotation reagent by figure 2 The multi-stage flotation of the "one rough - two sweep - five fine" depth flotation process is shown.

[0070] During the flotation process, after roughing, the rougher concentrate is subjected to 5-stage series selection, and the rougher tailings are subjected to 2-stage series selection;

[0071] In beneficiation, the sel...

Embodiment 2

[0084]The coal slurry sample was taken from the dense pool bottom flow of a coal washing plant in Panxian County, Guizhou Province, with a water content of 65.4%, an ash content of 41.25% (dry basis), and a sulfur content of 1.25% (dry basis).

[0085] Step (1): After the raw coal slurry is classified-grinding, the grinding fineness is controlled to be -0.074mm, accounting for more than 78%; the solid content of the slurry after grinding is 28.8%;

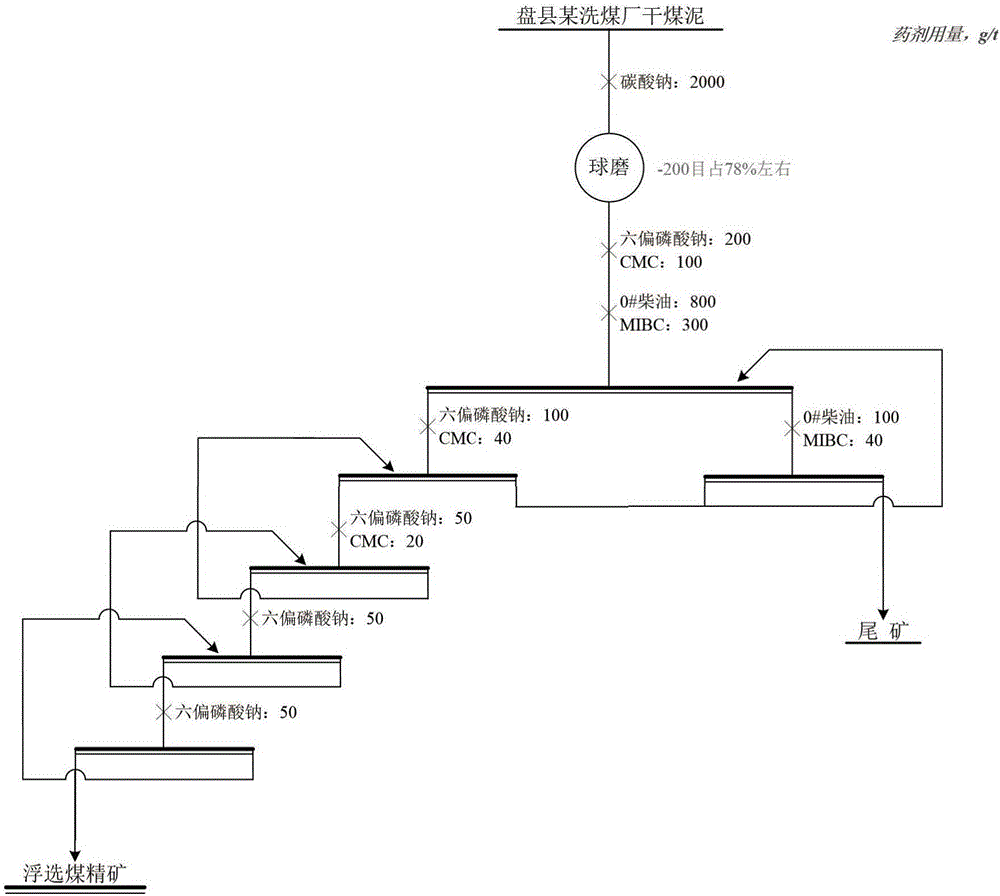

[0086] Step (2): the ore pulp of step (1) is adjusted with water, makes the solid content in the selected ore pulp obtained be 25%, press subsequently image 3 The "one rough - one sweep - four fine" deep flotation process is shown. During the flotation process, after roughing, the roughing concentrate is subjected to 5-stage series selection, and the roughing tailings are subjected to 2-stage series selection;

[0087] Described flotation agent is sodium carbonate (flotation regulator), sodium hexametaphosphate, CMC (inhibitor), 0...

Embodiment 3

[0094] Compared with Example 2, the difference is that in step (4), 300 g / t of dispersant polycarboxylate (commercially available polycarboxylate water-reducer) is added to the coal fines filter cake, and a twin-shaft agitator is used to pre-stir for 60 min , and then vigorously stirred for 180 min at a stirring speed of 800 rpm to form a slurry with a certain fluidity (viscosity of 1120 mPa·s).

[0095] In step (5), 100 g / t of polyvinyl alcohol as a stabilizer is added to the slurry obtained in step (4), and the stirring and homogenization are continued for 30 minutes to obtain the final coal water slurry product. After testing, the concentration of the coal-water slurry product is 65.7%, the ash content of the coal-water slurry base is 5.35%, the sulfur content is 0.45%, the fluidity is good, the viscosity of the coal-water slurry is 1120mPa·s, and no hard precipitation occurs after standing for 72 hours. According to calculations, 1 ton of coal slurry with a water content o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com