Application of Penicillium oxalicum EU2101 in preparation of cellulase preparation and degradation of cellulose

A EU2101, a technology for degrading cellulose, applied in the direction of enzymes, enzymes, hydrolase, etc., can solve problems such as large gaps in industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] Embodiment 1, the identification of Penicillium oxalicum EU2101

[0157] Penicillium oxalicum EU2101 is among the original fungal strains in the laboratory of the inventor of the present application. After mutagenesis, the strain with higher cellulase-producing activity was obtained through screening. Using Penicillium oxalicum wild-type strain HP7-1 (CGMCC No.10781) as the starting strain, three rounds of Co 60 - Gamma ray irradiation, obtained a mutant strain TCO7-4 whose filter paper enzyme activity was higher than that of the original strain HP7-1. Then TCO7-4 and its mutant strain EU122 were subjected to combined mutagenesis and screening with ethyl methylsulfonate (EMS) and ultraviolet (ultraviolet, UV) to finally obtain the mutant strain EU2101.

[0158] The specific operation is to carry out Co 60 When γ-rays are irradiated, the spore suspension with a lethal rate of about 85% is selected for large-scale isolation and screening of the mutant strains; while the...

Embodiment 2

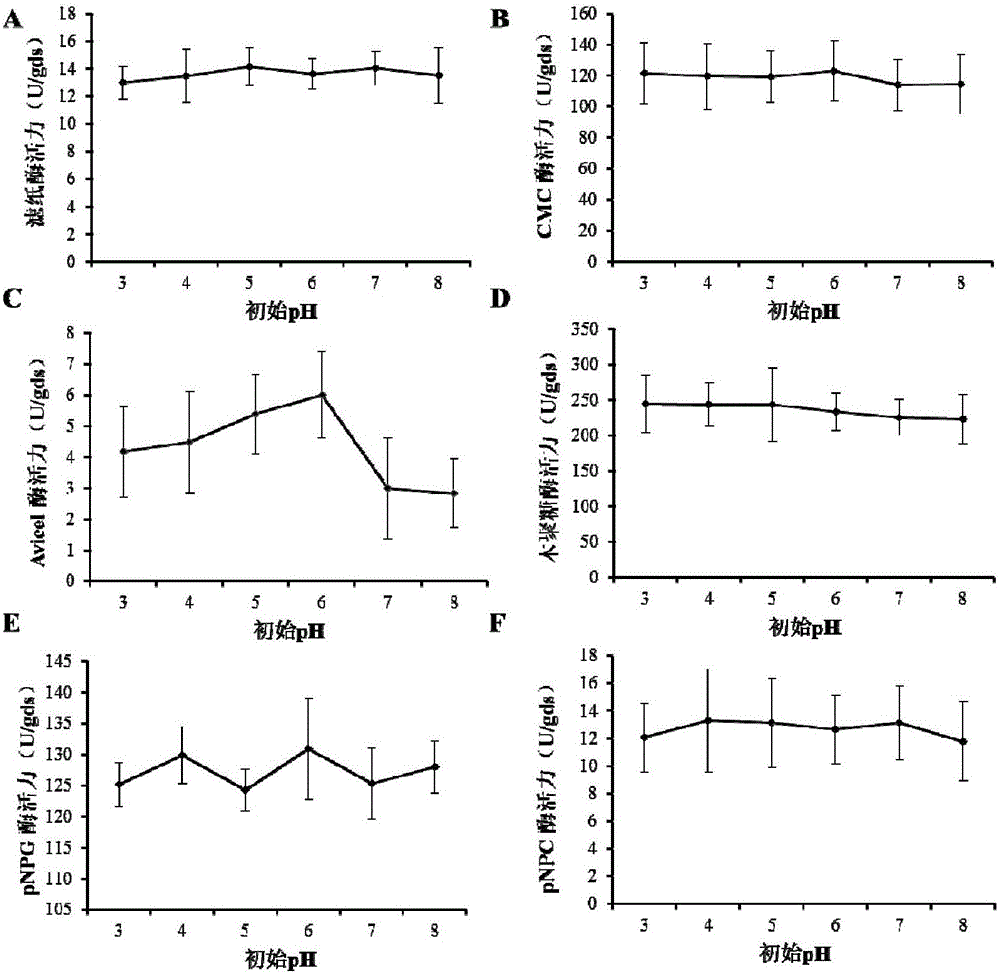

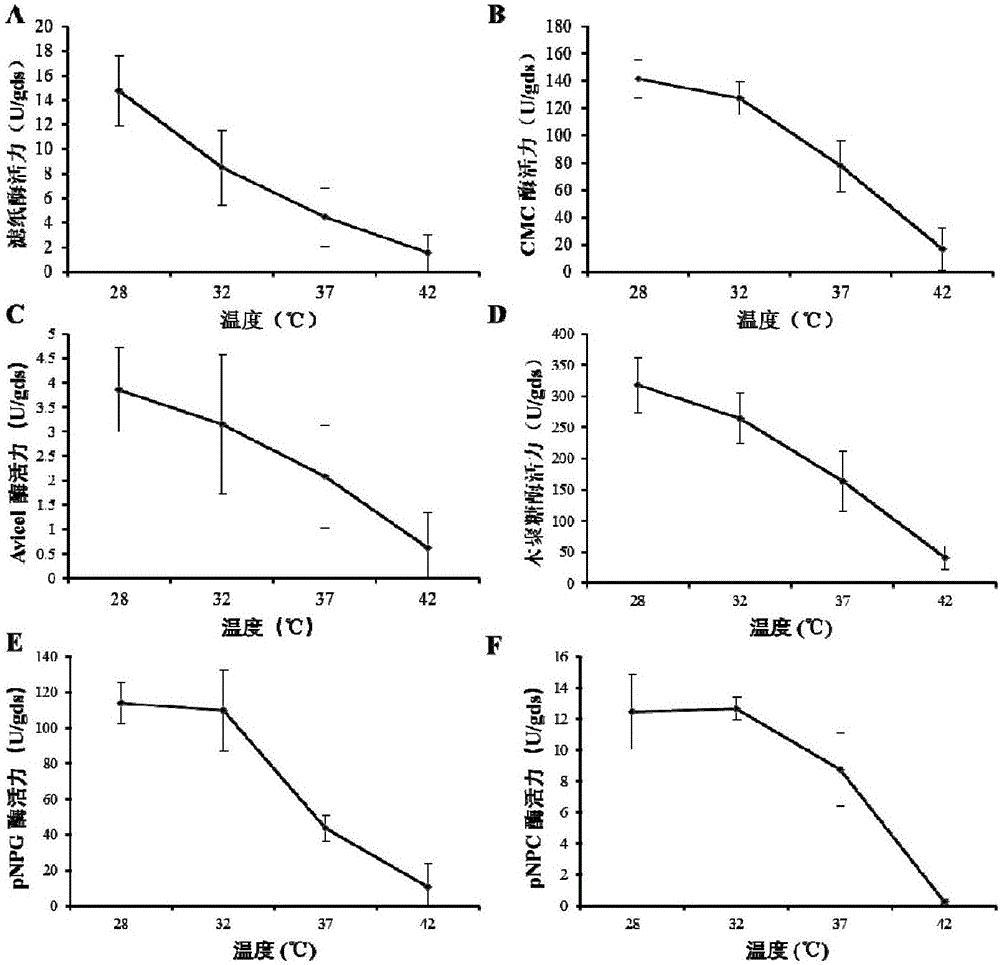

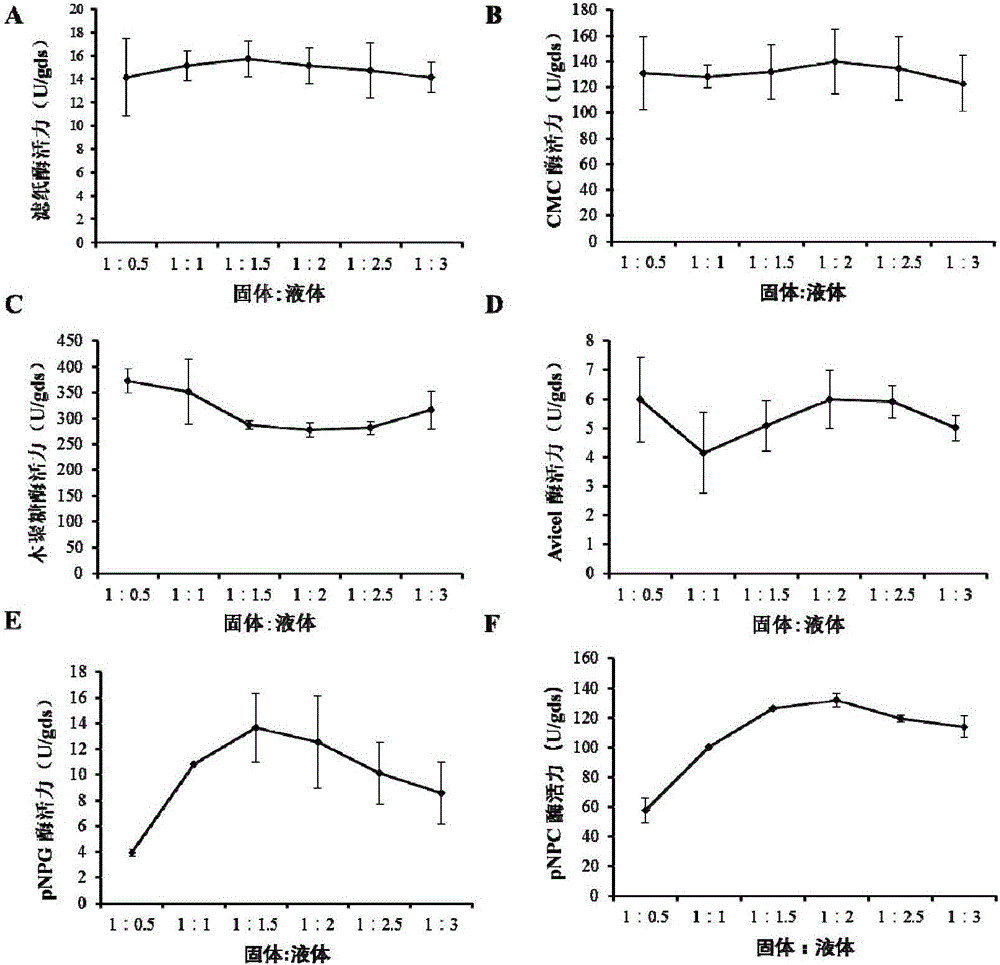

[0160] Example 2, Optimization of Cellulase Production Conditions by Penicillium oxalicum EU2101 Solid-state Fermentation

[0161] The experiment was repeated three times, and the specific steps of each repeated experiment were as follows:

[0162] 1. Preparation of spore suspension

[0163] 1. Sterilize the PDA solid medium at 115°C for 30 minutes to obtain a PDA plate.

[0164] 2. Wash the Penicillium oxalicum EU2101 spores cultivated on the PDA plate for 5 days with 0.1% (v / v, volume percentage concentration) Tween 80 aqueous solution, and the preparation concentration is 1×10 8 per mL of spore suspension.

[0165] 2. Optimization of the initial pH of the medium

[0166] 1. Preparation of fermentation media with different pH

[0167] Preparation of basic medium: the basic medium is composed of wheat bran and salt solution, wherein the proportion of wheat bran and salt solution is 10.0g:20mL. Salt solution consists of water, KH 2 PO 4 , (NH 4 ) 2 SO 4 , MgSO 4 ·7H...

Embodiment 3

[0230] Embodiment 3, utilize Penicillium oxalicum EU2101 to prepare cellulase preparation

[0231] 1. Preparation of fermentation medium

[0232] Prepare the optimal culture medium in Step 9 of Example 2.

[0233] 2. Preparation of spore solution

[0234] (1) Sterilize the PDA solid medium at 115° C. for 30 minutes to obtain a PDA plate.

[0235] (2) Penicillium oxalicum EU2101 was inoculated on a PDA solid plate, and placed in a constant temperature incubator at 28° C. for 5 days. The Penicillium oxalicum EU2101 spores cultivated on the PDA plate for 5 days were washed with 0.1% (volume percentage concentration) Tween 80 aqueous solution, and transferred to a 50 mL centrifuge tube containing several glass beads. Under the microscope, count the hemocytometer and adjust the spore concentration to 10 8 cells / mL, inoculated into the optimal medium above at an inoculum size of 10% (v / w).

[0236] 3. Preparation of cellulase preparation

[0237] (1) The fermentation medium in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com