Encapsulated and networked regenerated cellulose phase-change fiber and preparation method thereof

A technology of regenerated cellulose and phase change fiber, applied in the field of textile materials, can solve the problems of limited fiber application, easy agglomeration of microcapsules, limited thermal energy storage, etc., and achieve the effects of increasing the proportion, not easy to agglomerate, and uniform in size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

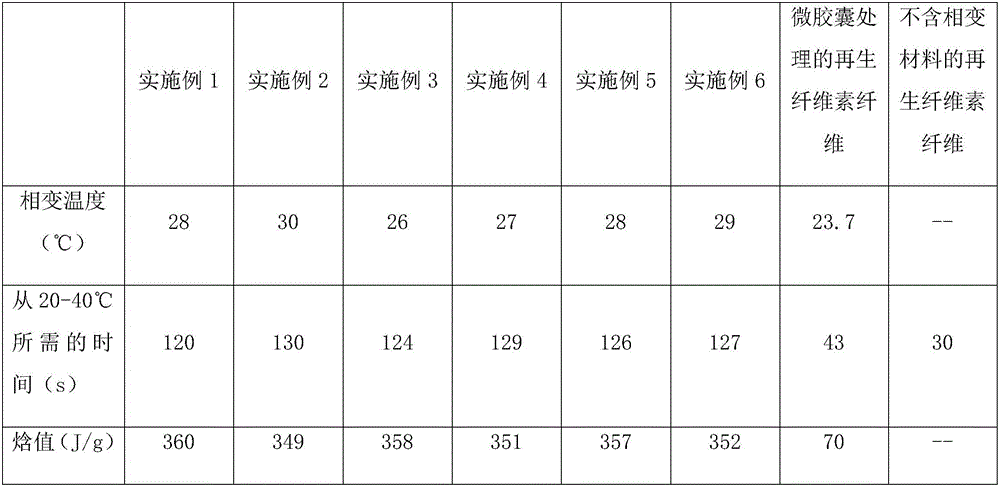

Examples

Embodiment 1

[0028] (1) In parts by mass, 1 part of glyceryl tristearate phase change material is added into 5 parts of chitosan solution with a mass fraction of 2%, fully stirred, and 2 parts of N, N methylenebis Acrylamide cross-linking agent and 0.8 parts of ammonium persulfate initiator are stirred evenly to form a microcapsule solution.

[0029] (2) In parts by mass, add 5 parts of sodium alginate powder and 3 parts of nano-silver powder to 100 parts of regenerated cellulose solution with a mass fraction of 15%, stir well, add 10 parts of glutaraldehyde crosslinking agent, and stirred evenly to form a cellulose spinning matrix.

[0030] (3) In parts by volume, the cross-section of the microcapsule solution packed into the spray hole is circular, and the diameter of the spray hole is a spray device of 25 μm. Under the working pressure of 0.3mPa, the microcapsule solution is evenly sprayed onto the spray hole. 80 parts of the cellulose spinning substrate were rapidly stirred at a speed...

Embodiment 2

[0033] (1) In parts by mass, add 1 part of glyceryl tristearate phase change material into 10 parts of chitosan solution with a mass fraction of 5% and fully stir, add 3 parts of N, N methylenebis Acrylamide crosslinking agent and 1.5 parts of ammonium persulfate initiator are stirred evenly to form a microcapsule solution.

[0034] (2) In parts by mass, add 8 parts of sodium alginate powder and 3-6 parts of nano-silver powder to 100 parts of regenerated cellulose solution with a mass fraction of 25%, stir well, and add 15 parts of glutaraldehyde Cross-linking agent, stir evenly to form cellulose spinning matrix.

[0035] (3) by volume, the cross-section of the microcapsule solution of 20 parts is packed into spray hole is circular, and the diameter of spray hole is the spray device of 100 μ m, under 0.4mPa working pressure, the microcapsule solution is evenly sprayed onto Into 100 parts of cellulose spinning substrate, stir rapidly at a speed of 5000 rpm / min, and at the same...

Embodiment 3

[0038](1) In parts by mass, add 1 part of glyceryl tristearate phase change material into 7 parts of chitosan solution with a mass fraction of 3%, fully stir, add 2.5 parts of N, N methylenebis Acrylamide crosslinking agent and 1.2 parts of ammonium persulfate initiator are stirred evenly to form a microcapsule solution.

[0039] (2) In parts by mass, add 6 parts of sodium alginate powder and 5 parts of nano-silver powder to 100 parts of regenerated cellulose solution with a mass fraction of 20%, stir well, add 15 parts of glutaraldehyde crosslinking agent, and stirred evenly to form a cellulose spinning matrix.

[0040] (3) In parts by volume, the cross section of the microcapsule solution packed into 15 parts of the spray hole is circular, and the diameter of the spray hole is a spray device of 50 μm. Under the working pressure of 0.35mPa, the microcapsule solution is evenly sprayed on the In 90 parts of cellulose spinning substrate, stir rapidly at a speed of 3000rpm / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com